Leak floor separating manure from urine

A slatted floor, manure separation technology, applied in animal houses, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve mutual pollution, increase the COD content of pig farm sewage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

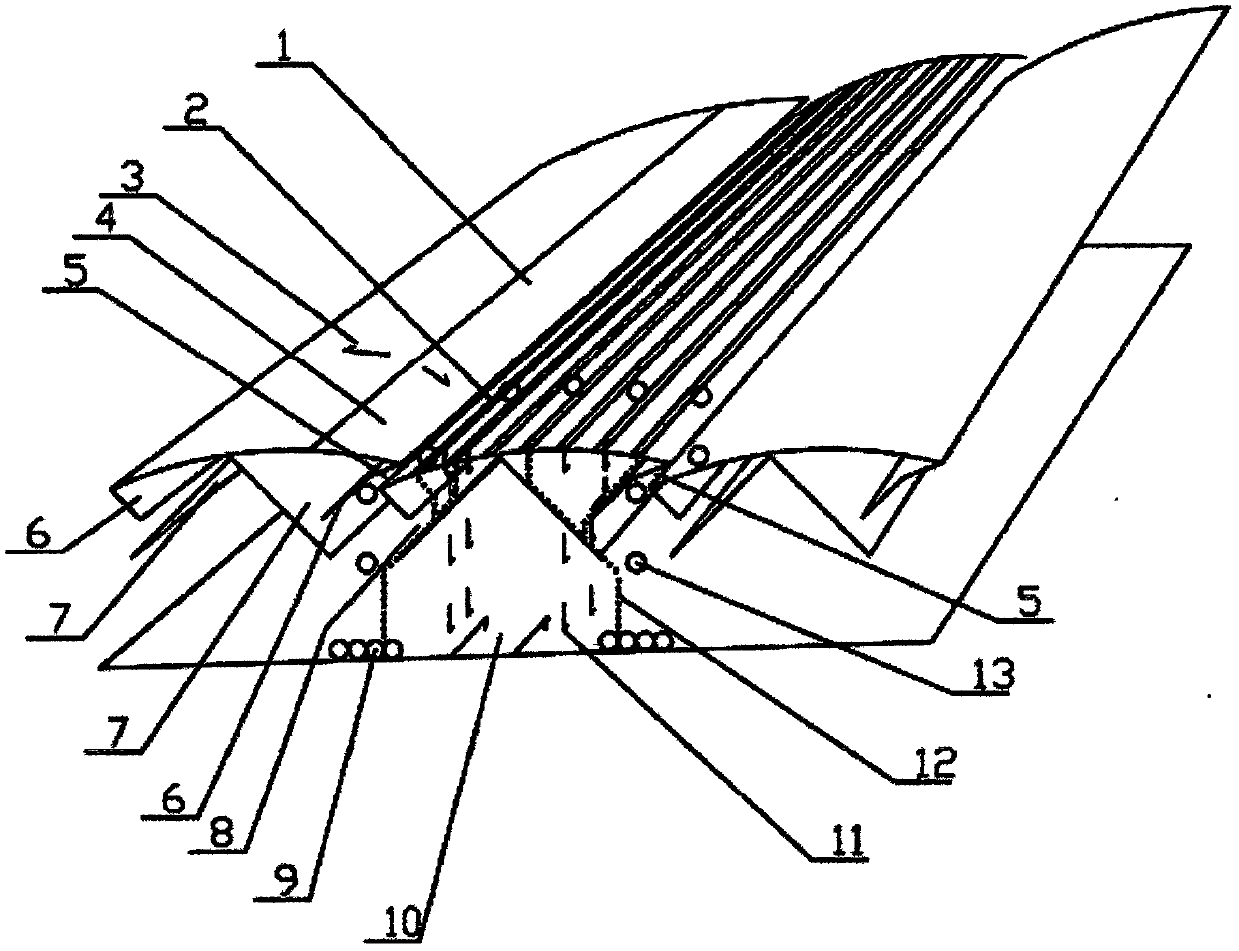

[0011] The excrement and urine separation slatted floor is an arc-shaped slatted floor 1 made of triangular steel or cast iron. The slats 2 of the slatted floor are straight and arranged in an arc shape. 1 is one centimeter wide, and the seam width is less than one centimeter, forming a slatted floor screen. The double slope of the slatted floor is divided into long slope 3 and short slope 4, and a small part of the long slope 3 is located at the bottom of the short slope 4 of the adjacent slatted floor , and leave a gap to form a slatted floor sieve to leak excrement gap 5. The slope of the arc-shaped slatted floor 1 is small, and the placement direction of the slats 2 can prevent slipping, so it does not affect the lying and movement of pigs, and has the function of a general slatted floor. The diameter of normal pig manure is generally greater than one centimeter, so after pig excretion, the pig manure 13 with a diameter greater than one centimeter moves along the double sl...

Embodiment 2

[0013] At the bottom of the curved excrement leakage floor 1, there are two diversion membranes 6 and two filter screens 7, which are at an angle of forty-five degrees to the horizontal plane. The diversion membrane 6 does not leak water, and the filter screen 7 leaks urine and excrement. Fixed on the bottom of the arc-shaped slatted floor 1 through the fixing rod, the diversion film 6 is located at both ends, the filter screen 7 is located in the middle, and a part of the diversion film 6 is on the upper part of the filter screen 7 to form a mesh screen, the diversion film 6 and the filter screen Leave gap between 7, be omentum sieve leakage excrement gap 8. The pig manure 13 with a diameter greater than one centimeter may be broken when moving along the double slope, producing pig manure 12 with a diameter less than one centimeter, which falls through the seams between the slats 2 of the arc-shaped slatted floor 1 and falls to the guide of the omentum sieve. On the flow film...

Embodiment 3

[0015] The manure ditch floor supporting the excrement and urine separation slatted floor has a certain slope, and is divided into a manure ditch floor manure collection area 9 and a manure ditch floor urine collection area 10 . The urine 11 flows away in real time, and the excrement is stored in the excrement collection area 9 on the floor of the excrement ditch, which is regularly removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com