ball screw

A technology of ball screw and lead screw, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problem of unrealized load distribution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

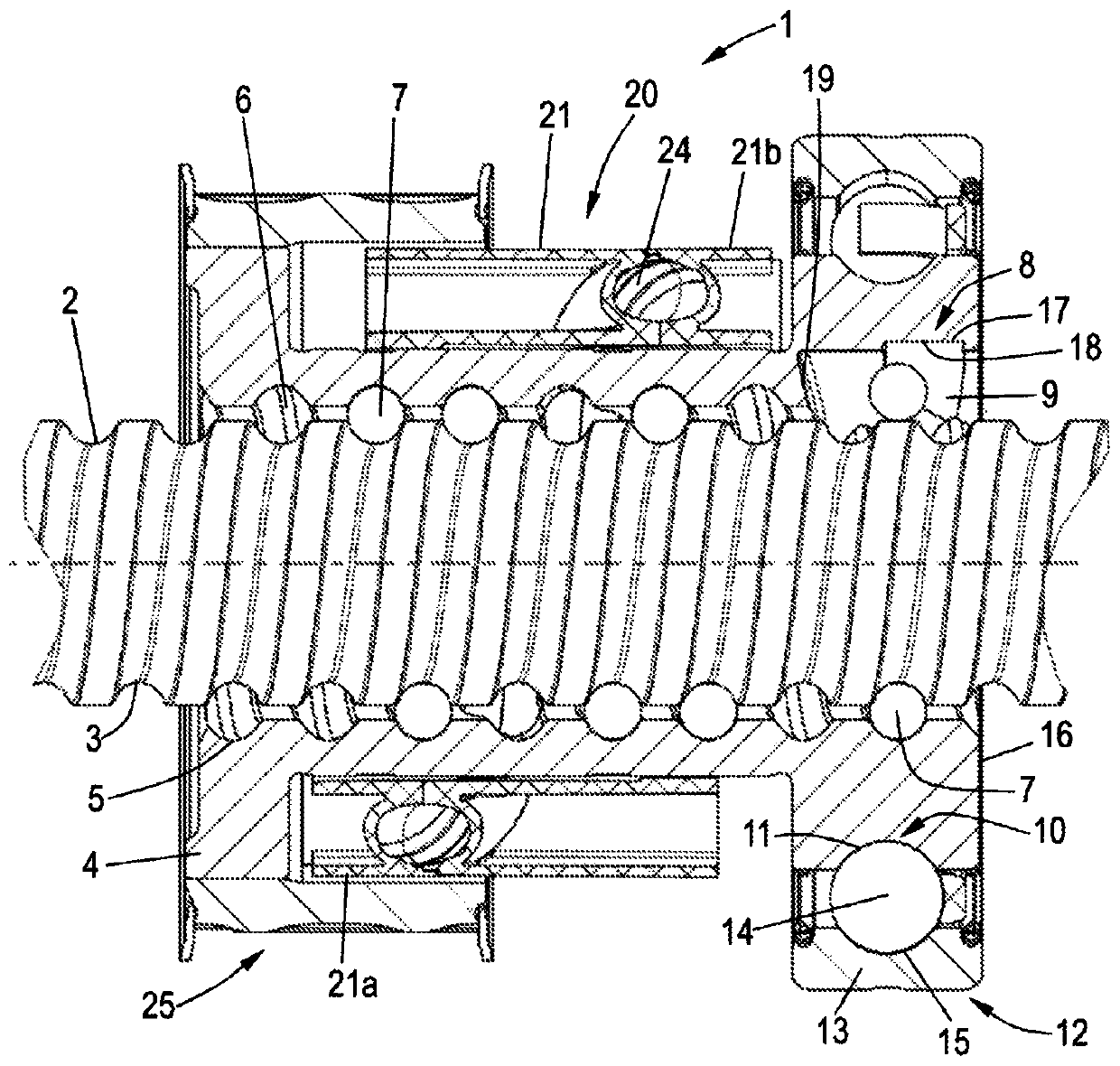

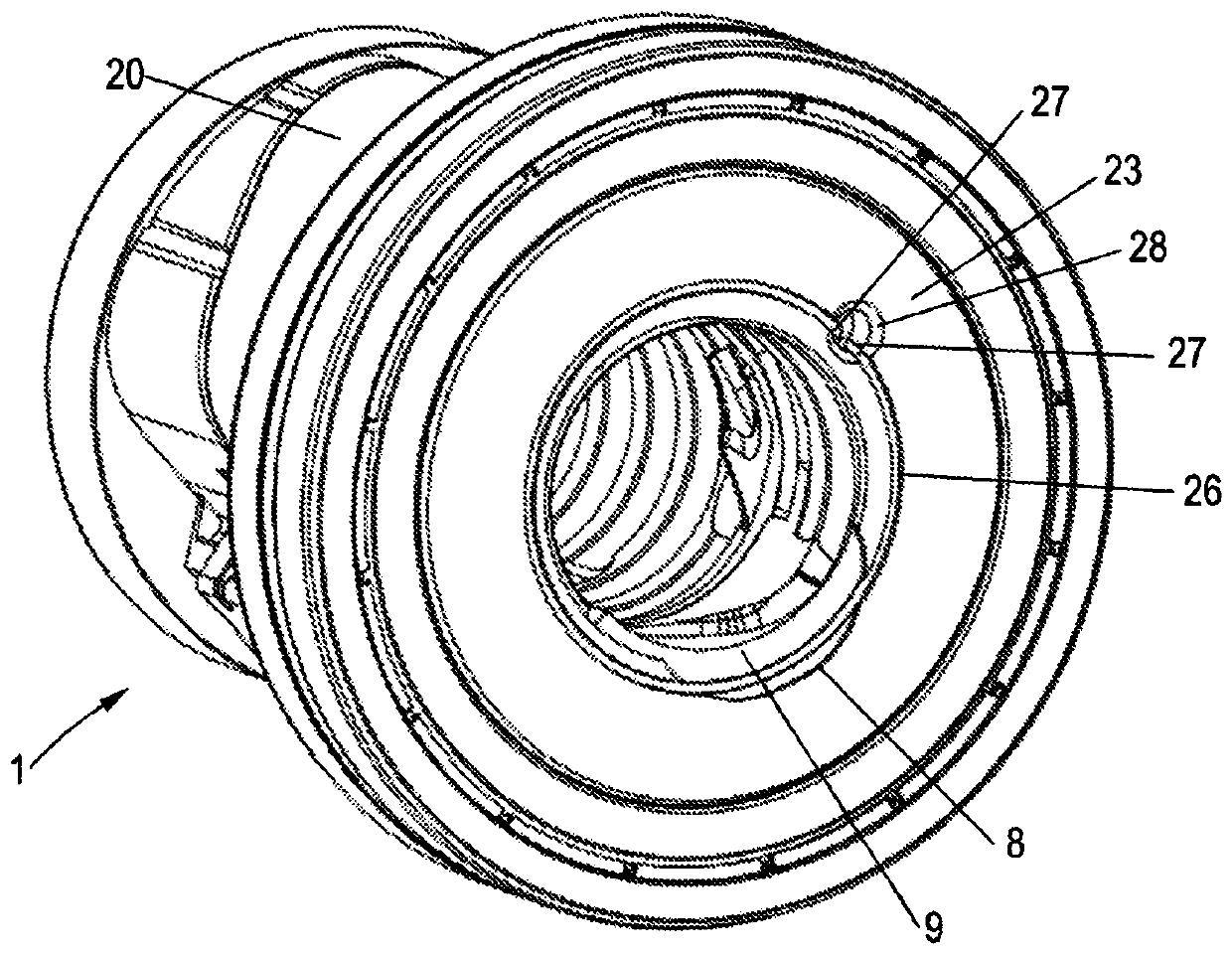

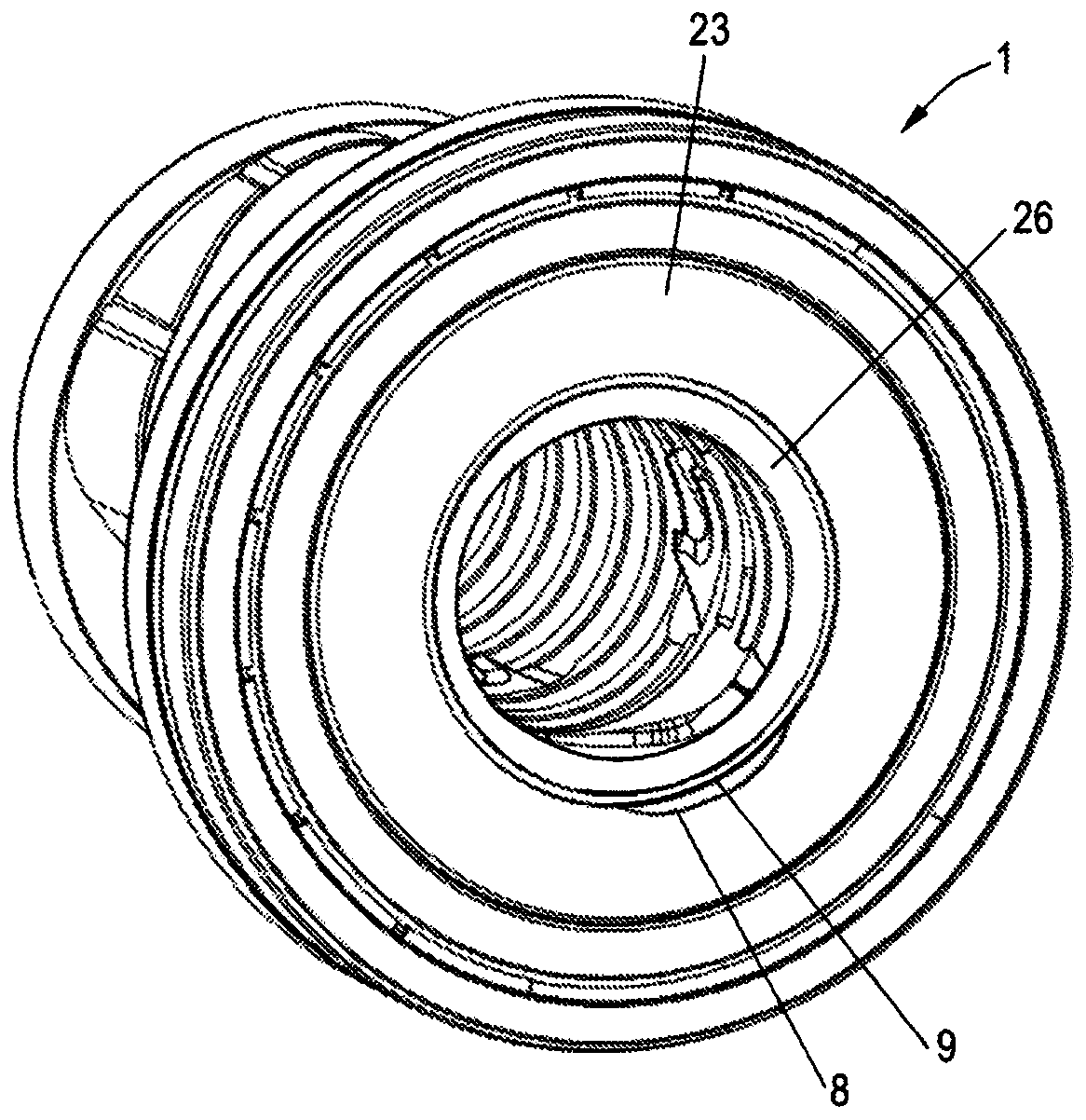

[0031] figure 1 Shows the ball screw 1 according to the present invention, the ball screw comprising: a screw 2 having a ball groove 3 formed on the outer side thereof; and a nut 4, the nut 4 being cut away here It is shown that the nut has a ball groove 5 formed on its inner side. The ball grooves 3 and 5 are supplemented in a known manner as a surrounding ball channel 6 in which the ball 7 travels.

[0032] On the inner side of the nut 4, namely in the ball groove 5, a groove 8 is formed in which a steering element 9 is housed, and the steering element is used to steer the ball 7 from one channel section to the adjacent In the channel section, a surrounding closed ball row is formed. The steering element 9 is formed as a single steering element by means of which the ball 7 is displaced from one channel section via a threaded shoulder into the directly adjacent channel section.

[0033] The groove 8 is closed radially. This makes it possible to form an integrated bearing geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com