Thread cutting device for column type sewing machine

A sewing machine and thread cutting technology, which is applied to the control device of the sewing machine, the mechanism of cutting the thread in the sewing machine, the components of the sewing machine, etc., and can solve the problem of short surface of the sewing object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

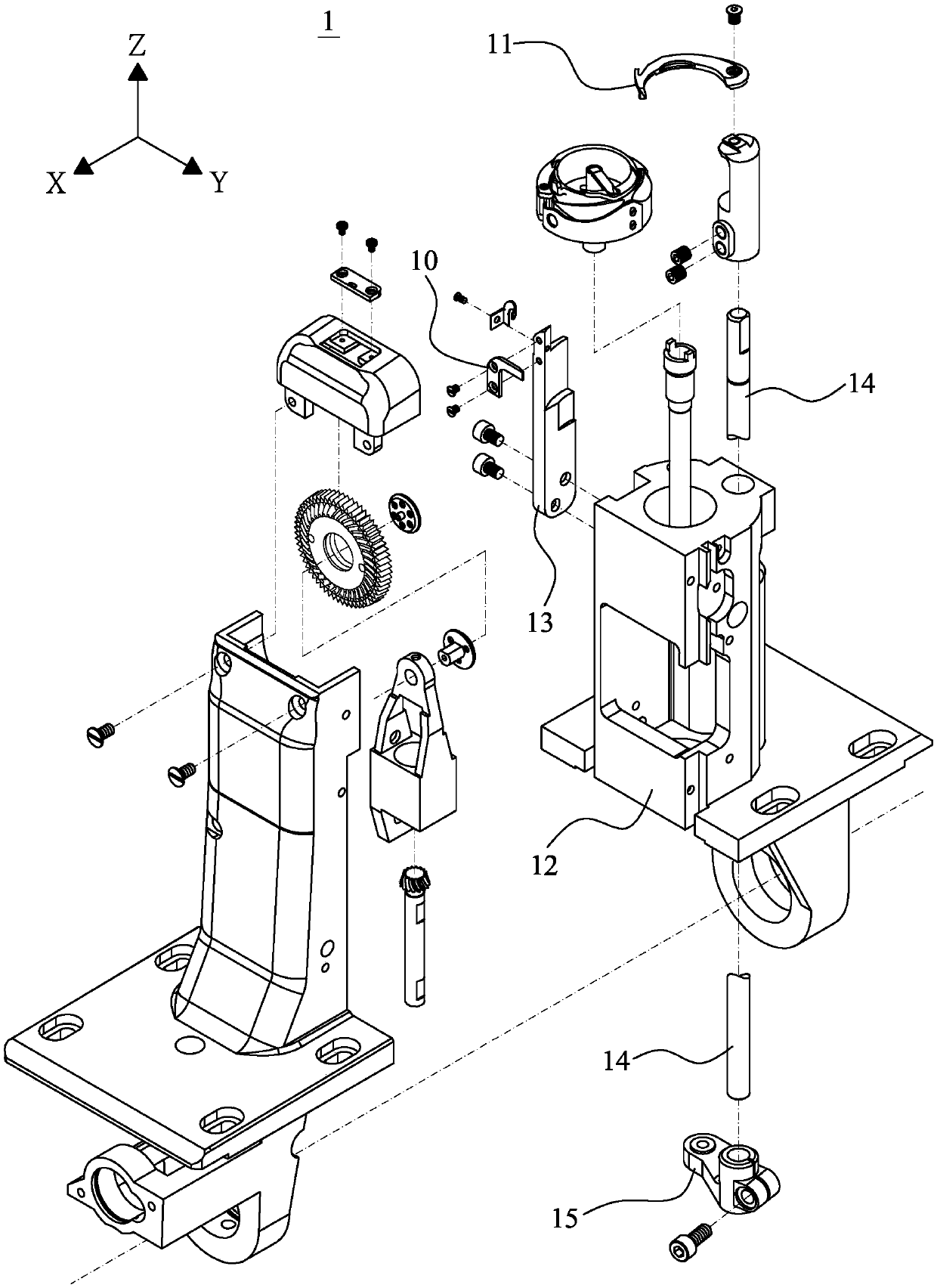

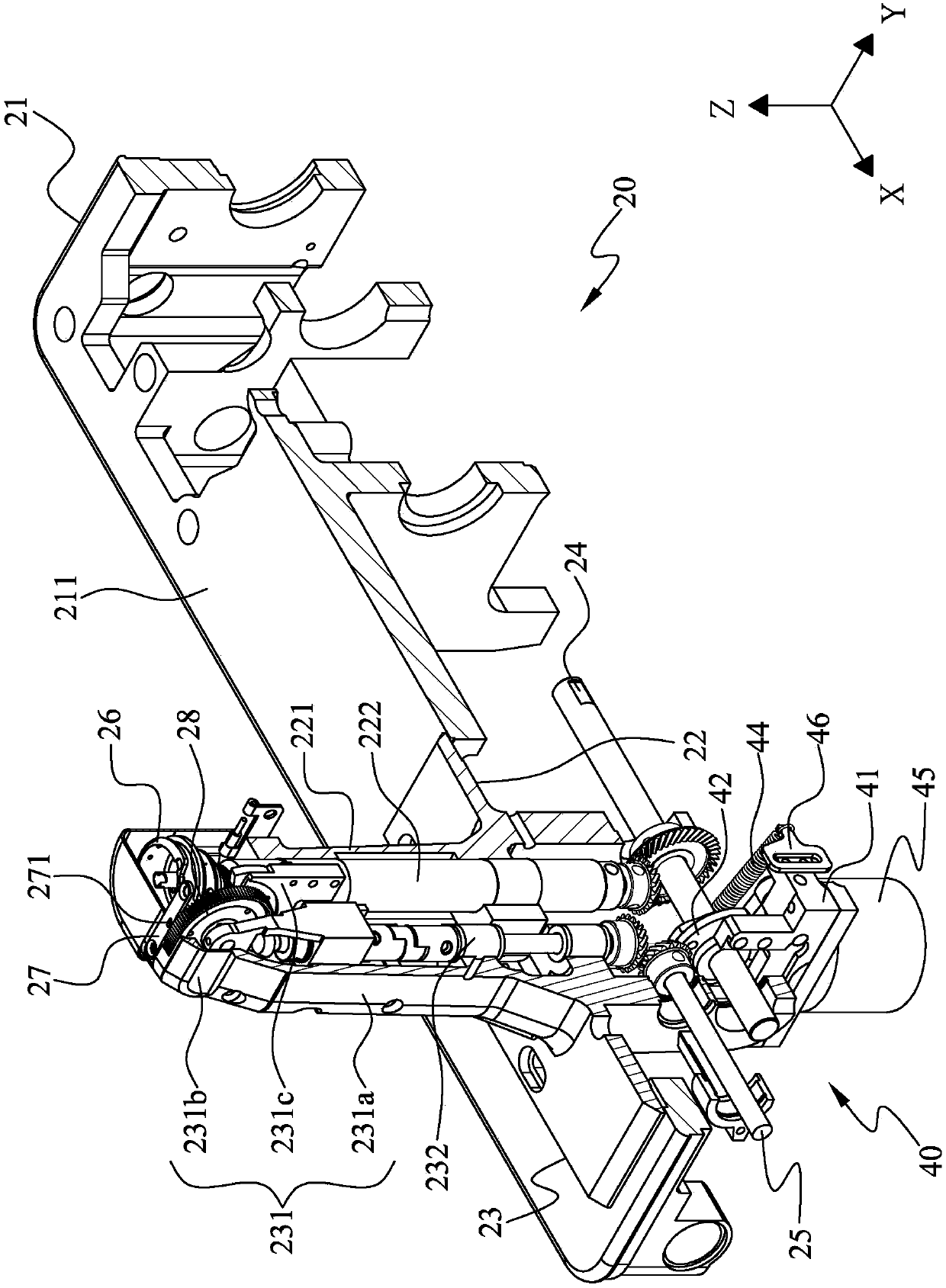

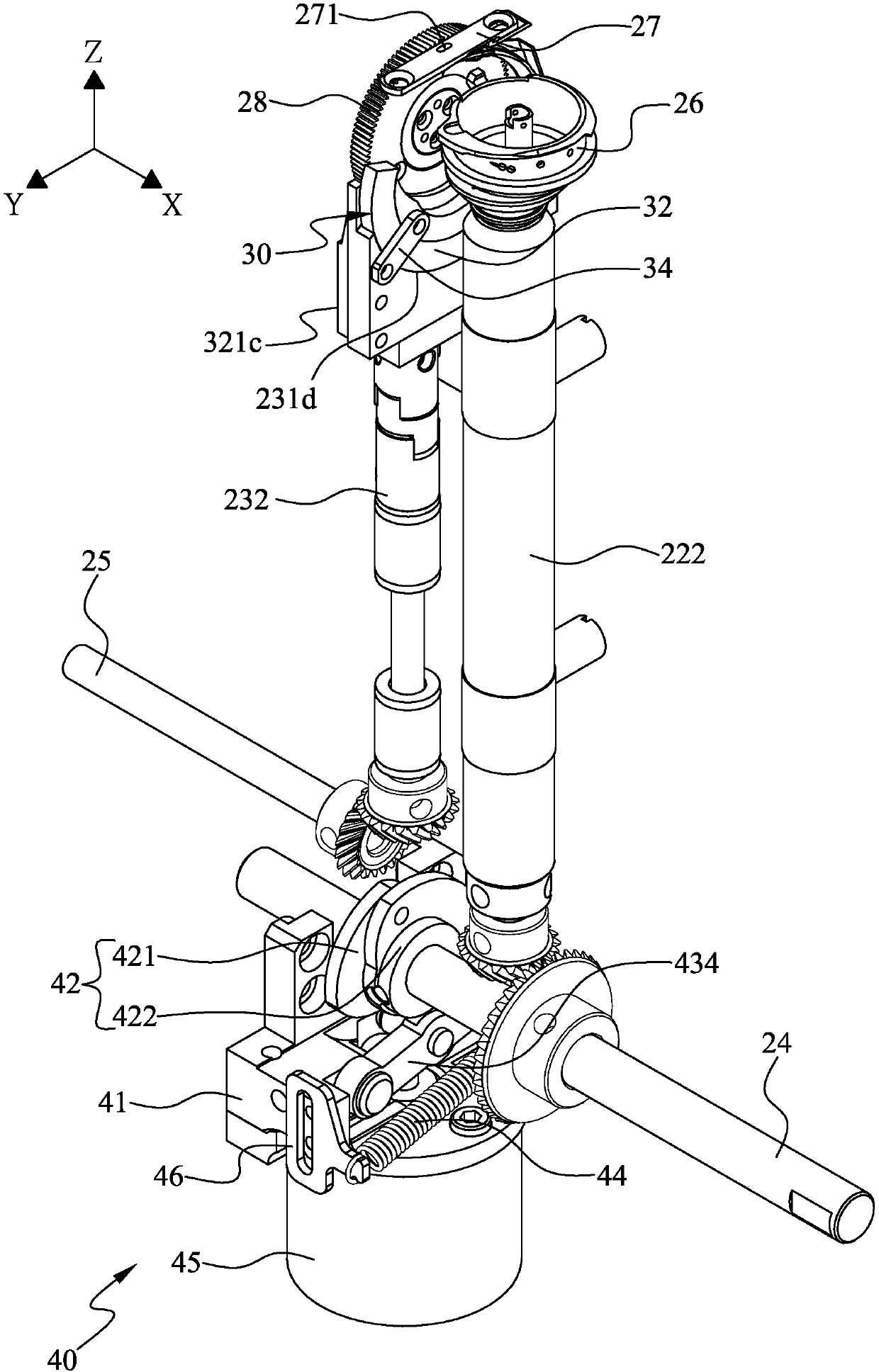

[0046] see figure 2As shown, the thread cutting device 2 of the present invention is mainly applied to a column type sewing machine 20. The column type sewing machine 20 has three parts: a head (not shown), a pillar (not shown) and a base 21, wherein the The base 21 forms a worktable 211, and the worktable 211 is equipped with a kettle shaft seat 22 that can be moved and adjusted along the X-axis direction and a side seat 23 on one side of the kettle shaft seat 22. The kettle shaft seat 22 It can selectively change the relative position with the machine needle on the head.

[0047] Please refer to figure 2 and image 3 As shown, the base 21 is provided with a lower shaft 24 and a lower feeding shaft 25, both of the lower shaft 24 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com