Rail butt joint structure

A kind of rail, relative sliding technology, applied in the direction of rail system, load hanging components, transportation and packaging, etc., can solve the problems of affecting safety, larger gaps, wheel jamming, etc., to ensure installation and docking accuracy, and improve safety. and reliability, the effect of avoiding wheel sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

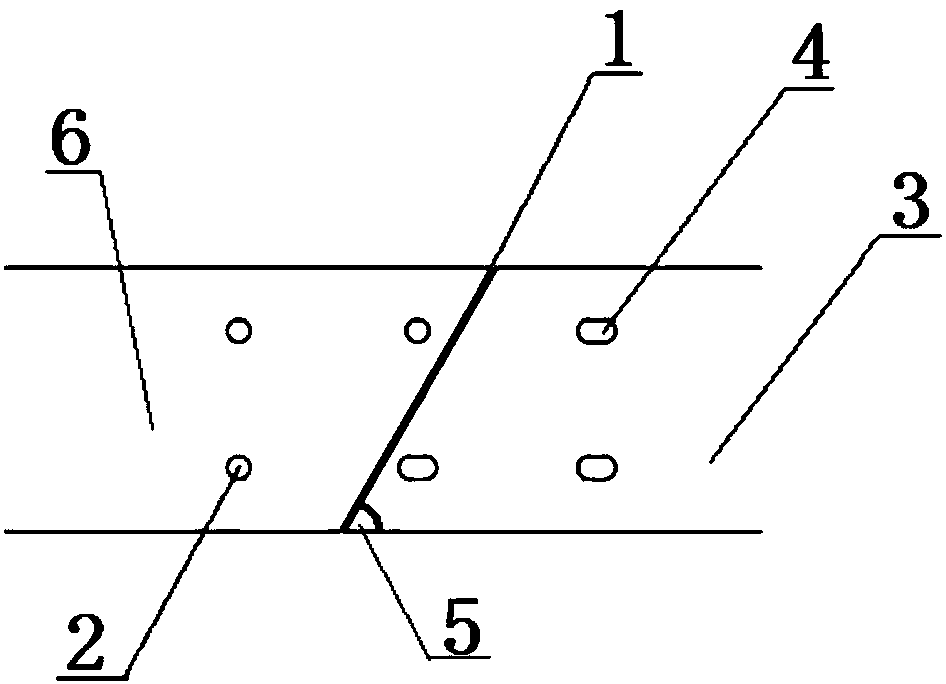

[0018] A track docking structure is specifically provided in conjunction with the accompanying drawings, including the first track 6 and the second track 3; there is a reserved seam between the end of the first track and the end of the second track; the extension direction of the reserved seam and the track It is at an inclination angle, and the inclination angle 5 is greater than 0° and less than 90°; the end of the first track is fixed through the round hole 2 of the bolt, and the end of the second track is fixed through the long hole 4 of the bolt. When the ambient temperature changes, the bolt and the long Relative sliding is formed between the holes; the other end of the first track has a long bolt hole, and the other end of the second track has a bolt round hole; the reserved seam is inclined at an angle of 45° to the extending direction of the track; the reserved The seam width is 2 to 3mm.

[0019] When the two rails are docked end to end, one side is a round hole for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com