Aeroengine blisk disintegrating device

An aero-engine and integral blisk technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of unfavorable decomposition of loosening force, occupying a large space, and requiring a crane, shortening decomposition time, improving production efficiency, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

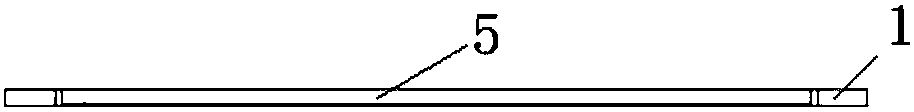

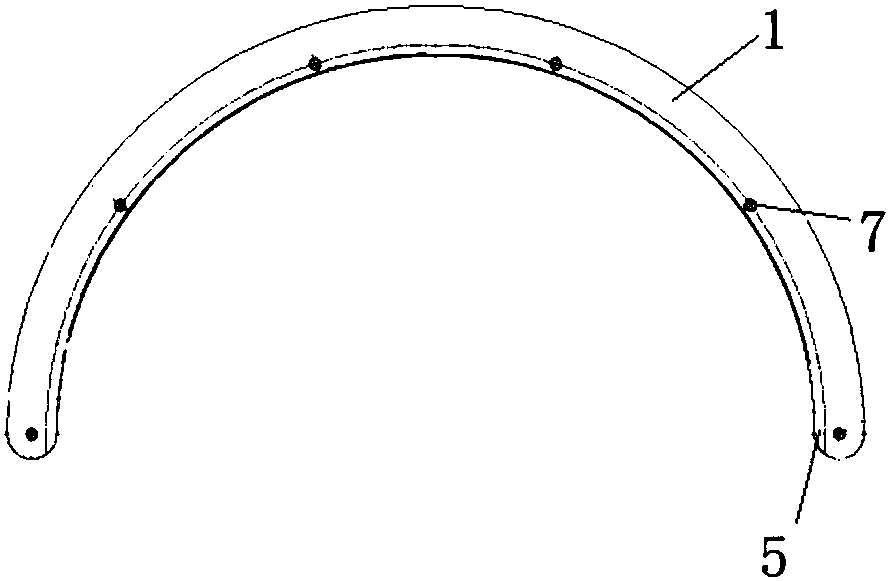

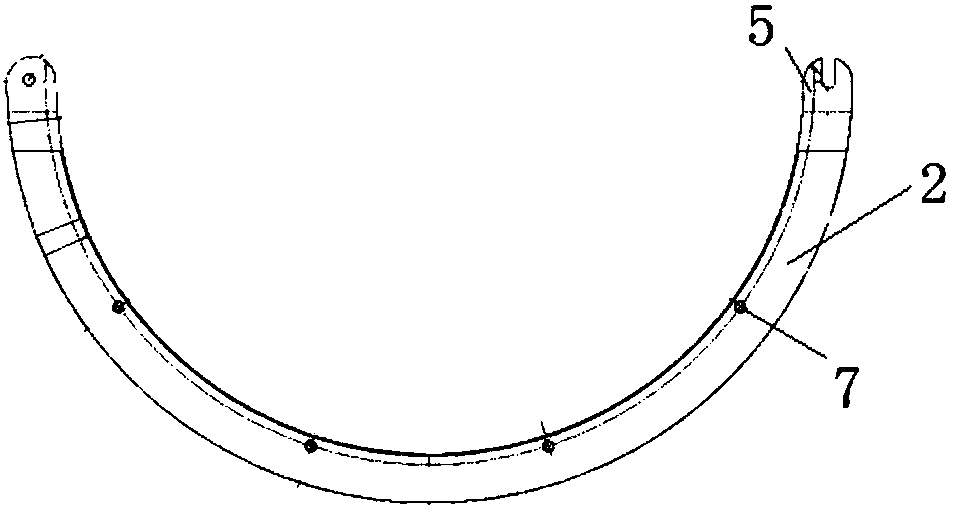

[0034] refer to Figure 1 to Figure 7, the whole blisk decomposition device of aero-engine includes left half ring 1 and right half ring 2, the diameter and thickness of left half ring 1 and right half ring 2 are the same, the thickness of left half ring 1 and right half ring 2 is according to two phases The distance between the adjacent blisks, the height of the studs and the smooth pressure block 4 is determined, the thickness of the left half ring 1 and the right half ring 2 meet the requirement that the fixed stud 3 does not unscrew the left and right half rings during the height adjustment process, and is The tool for rotating the nut of the fixed stud 3 leaves enough room for operation. There are 4 evenly arranged M8 threaded holes 7 on the left half ring 1 and the right half ring 2 respectively, which can be adjusted according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com