Rack drive type crawler bogie

A drive-type, rack-driven technology, applied in the field of rack-driven crawler trolleys, can solve problems such as high cost and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

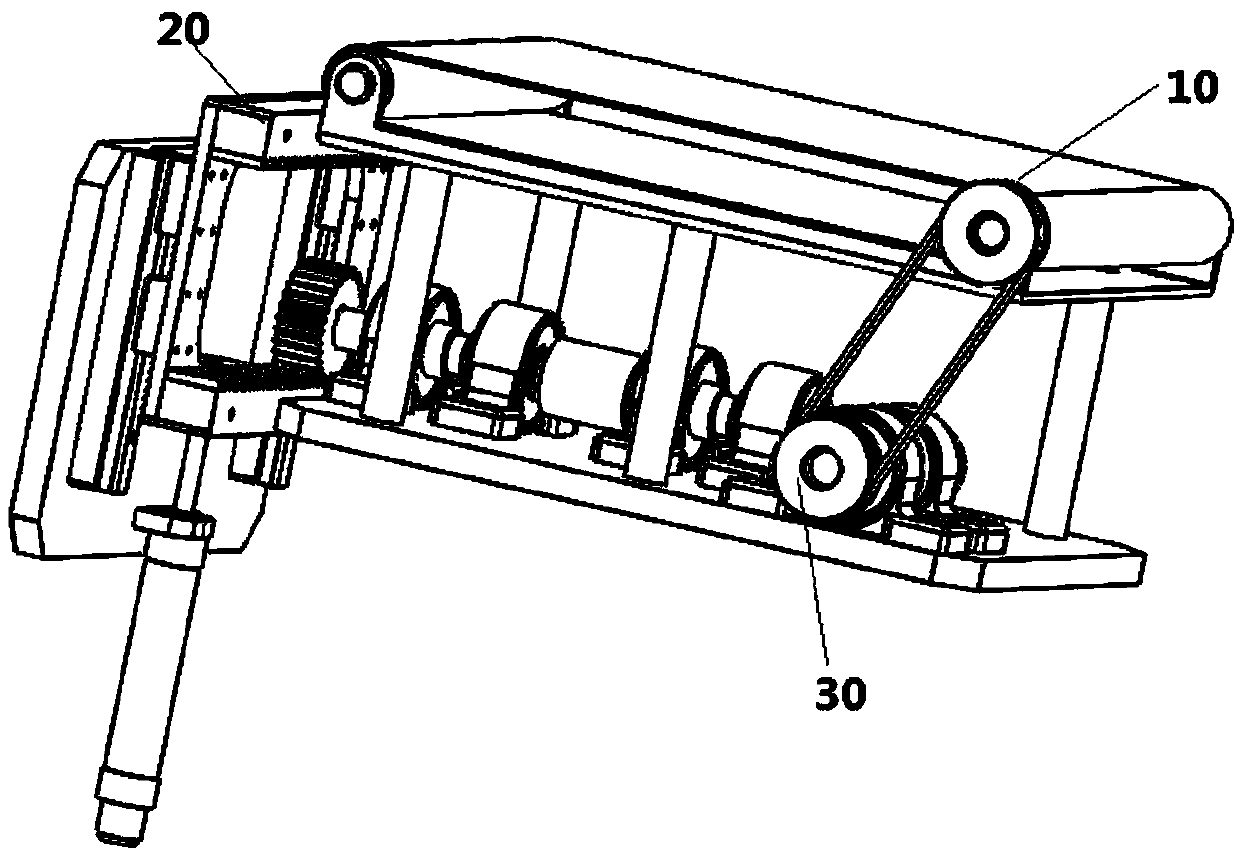

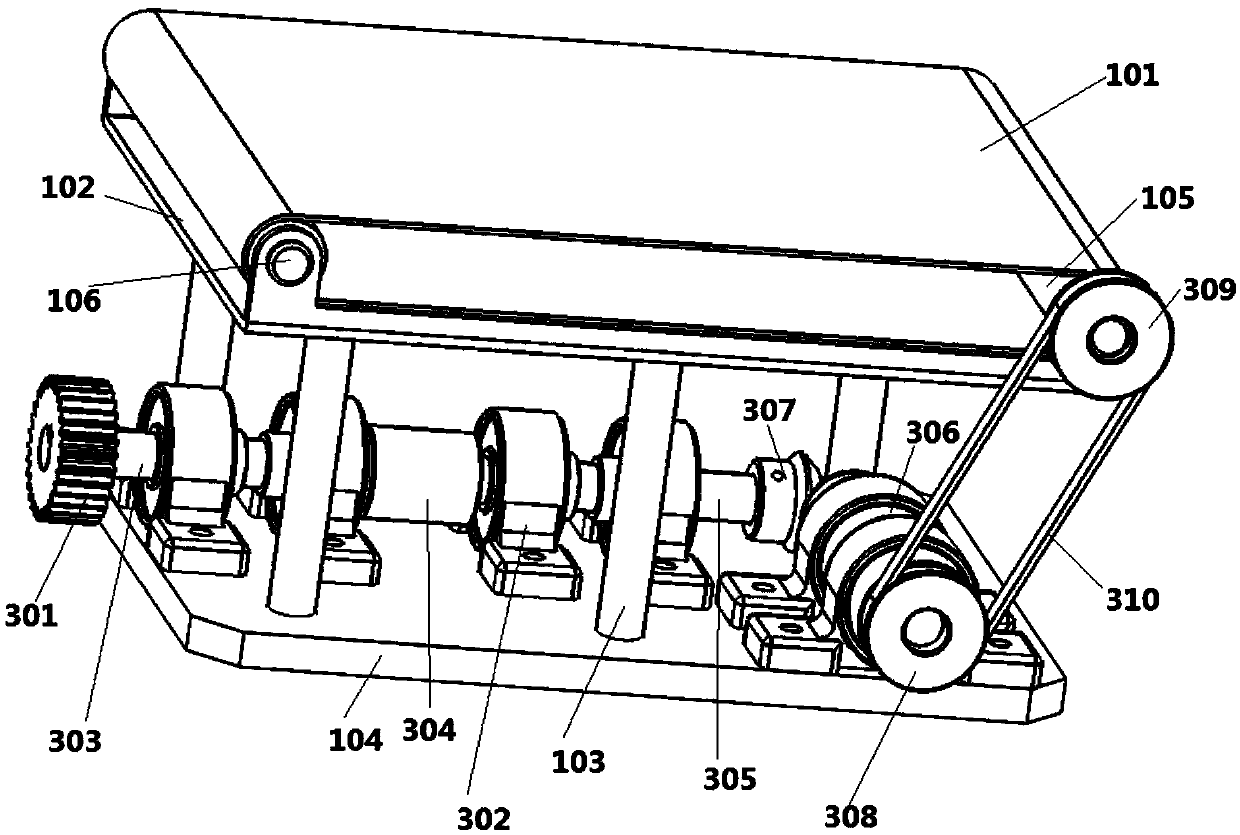

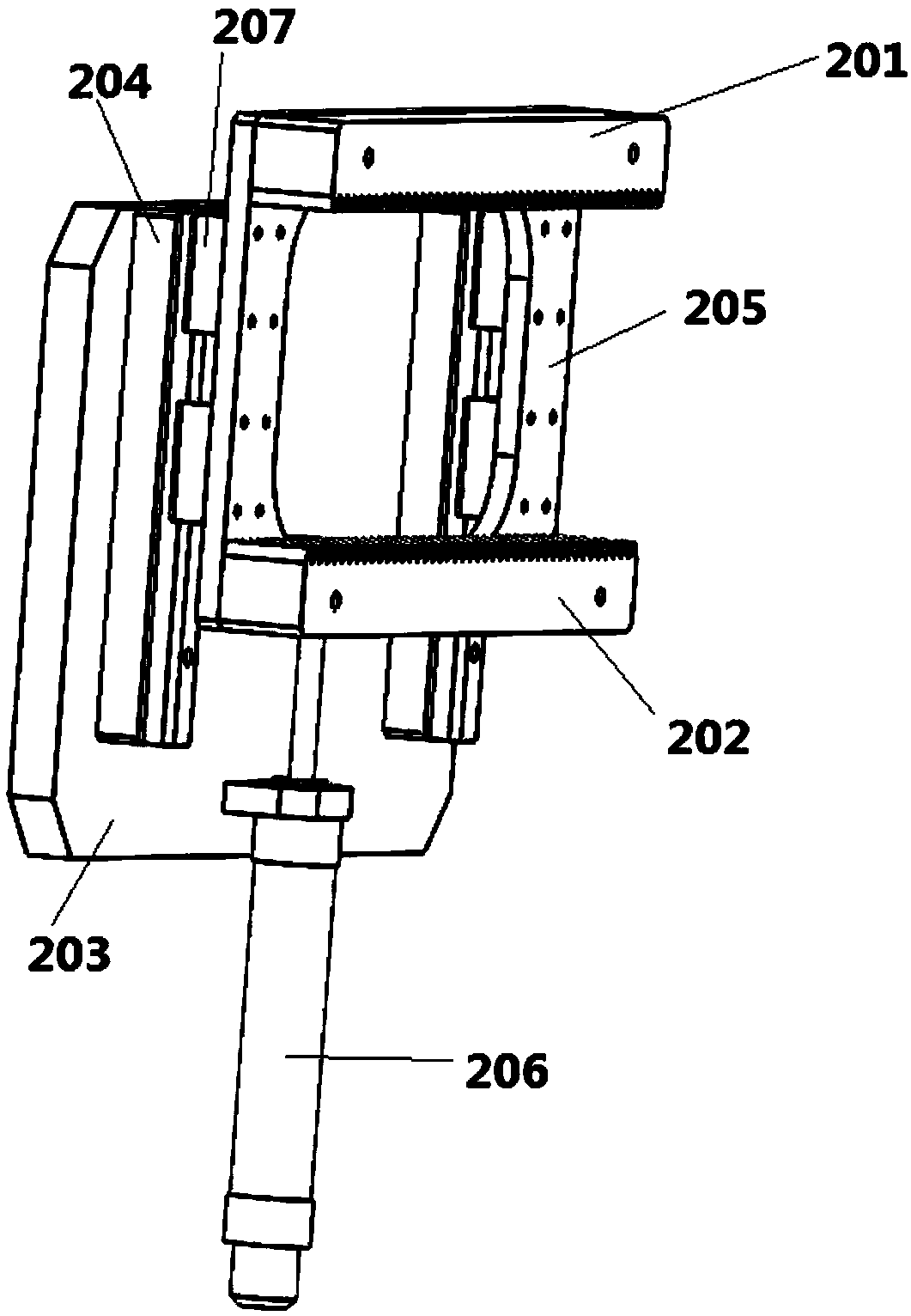

[0019] A rack driven crawler trolley comprises: a trolley main body 10 , a rack support 20 and a transmission device 30 .

[0020] The trolley main body 10 is provided with a crawler belt 101 for carrying and transporting goods, and the transport direction of the crawler belt 101 is perpendicular to the traveling direction of the trolley;

[0021] The trolley main body 10 includes a base plate 102, a connecting column 103 and a mounting plate 104. The top of the base plate 102 is provided with a driving roller 105 and a driven roller 106. The crawler belt 101 is sleeved on the driving roller 105 and the driving roller. The mounting plate 104 is disposed below the base plate 102 , the top of the connecting column 103 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com