Manufacturing method of multilayer circuit board

A technology of a multilayer circuit board and a manufacturing method, which is applied in the field of communication and can solve the problems of double-sided circuit diagram damage, circuit diagram deformation, unusability of the multilayer circuit board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In practical applications, when receiving the customer's demand for making a multi-layer circuit board, according to the customer's needs, the technicians will analyze the stack structure of the multi-layer circuit board to be produced, including substrate materials, prepreg materials, buried drilling, blind drilling and other information, so as to determine the number of layers of the multilayer circuit board to be made, and pre-design the design engineering design circuit diagram, MI instruction (Manufacturing Instruction, production instruction) and CAM (computer Aided Manufacturing, computer-aided Production) data, you can control the production process of multi-layer circuit boards through pre-set MI instructions and CAM data.

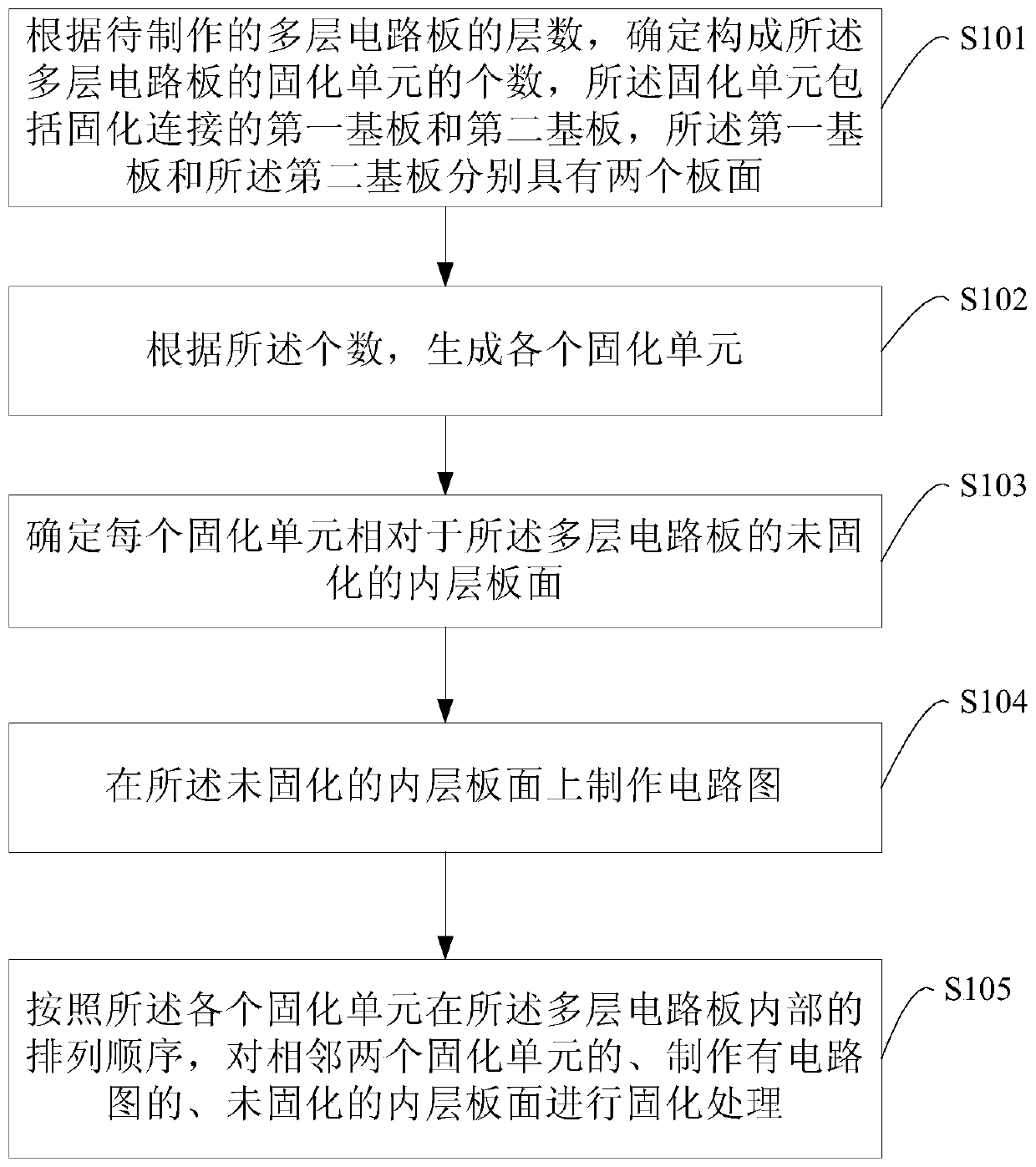

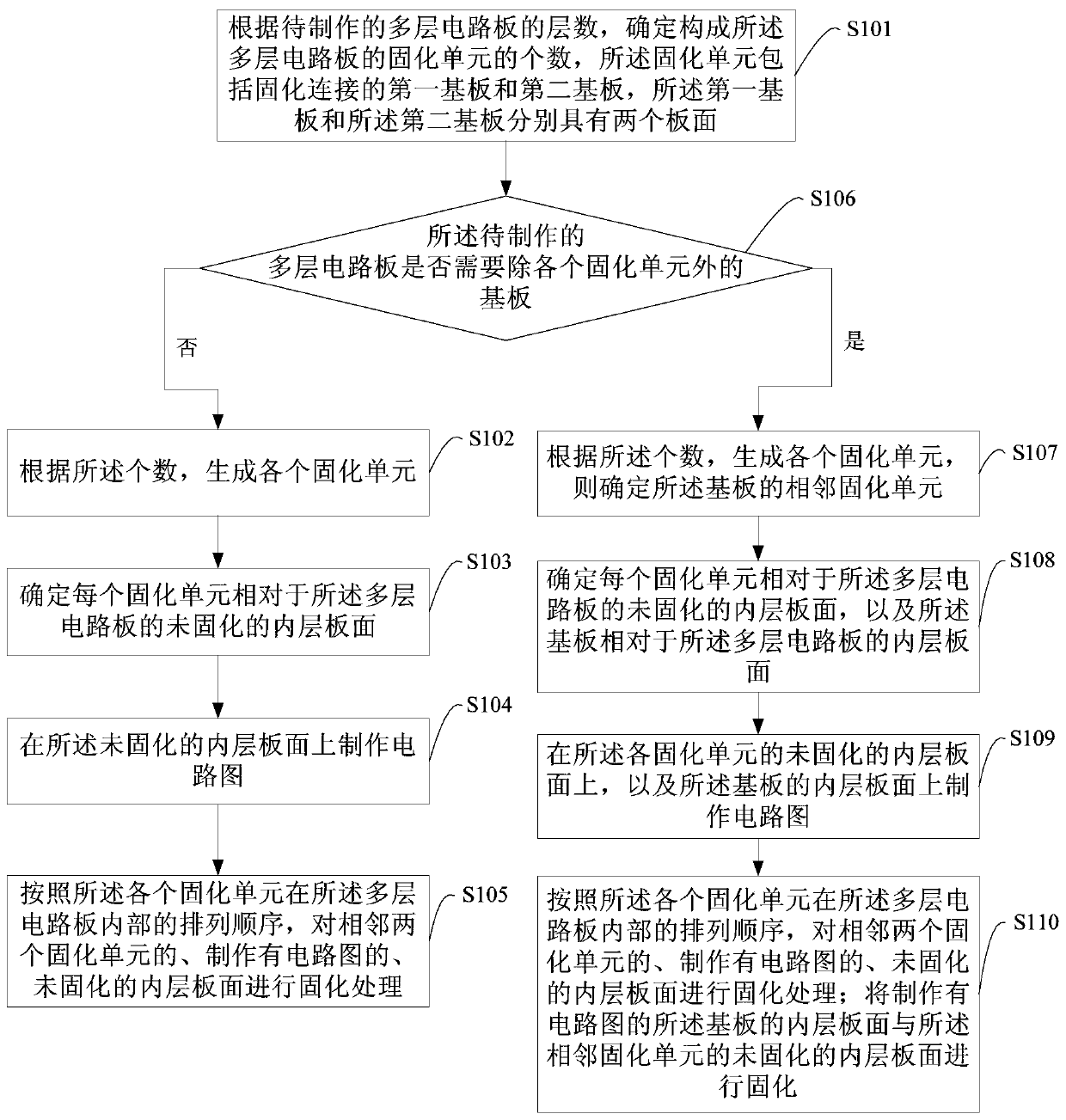

[0016] figure 1 It is a flow chart of the manufacturing method of the multilayer circuit board provided by Embodiment 1 of the present invention. The embodiment of the present invention aims at the fact that in the manufacturing process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com