A sorting method for decommissioned battery modules

A battery module and battery technology, which is applied in the repair/maintenance of secondary batteries, can solve the problem of high sorting costs, and achieve the effects of avoiding rapid capacity decay, saving costs, and improving sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

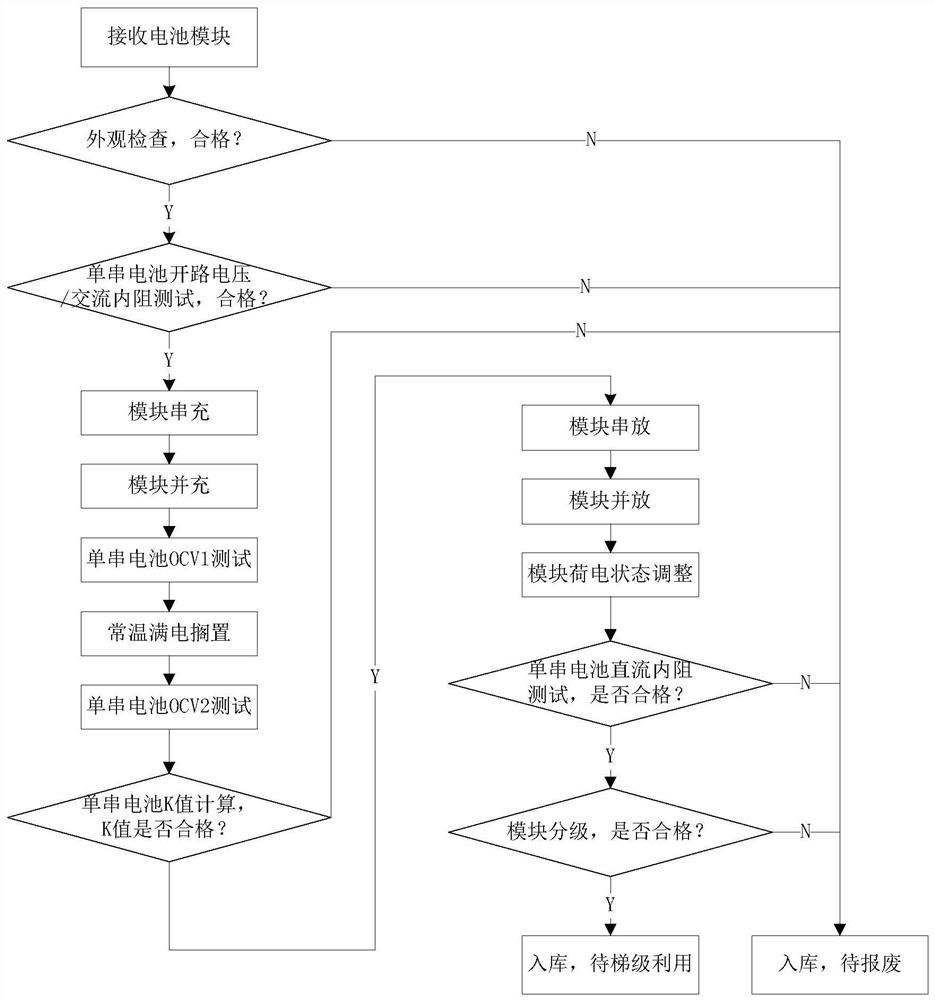

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

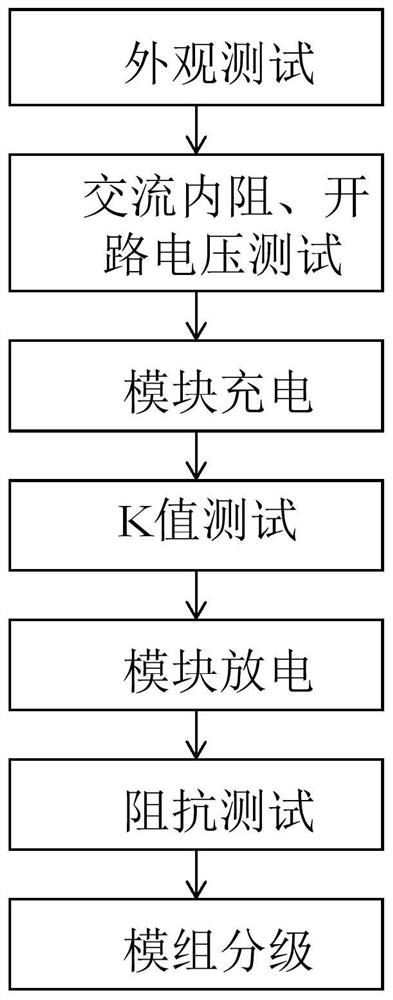

[0027] The decommissioned battery module of the present invention adopts the method of paralleling the single cells first and then connecting them in series. The module sorting method mainly includes the following steps:

[0028] Carry out constant current charging or constant voltage charging to the decommissioned battery module, and stop charging when the voltage of the decommissioned battery module or the voltage of the single cells therein reaches a first set value. Constant current charging or constant voltage charging is performed on each single string of batteries, and the cut-off mode for stopping charging of each single string of batteries is when the voltage of any single battery in the single string of batteries reaches the second set value. After charging is completed, conduct a K value test for each single string of batteries. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com