Permanganate index analyzer and permanganate index analysis method

A permanganate index and analyzer technology, which is applied in the direction of chemical analysis by titration method, can solve the problems of low precision and low efficiency, and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

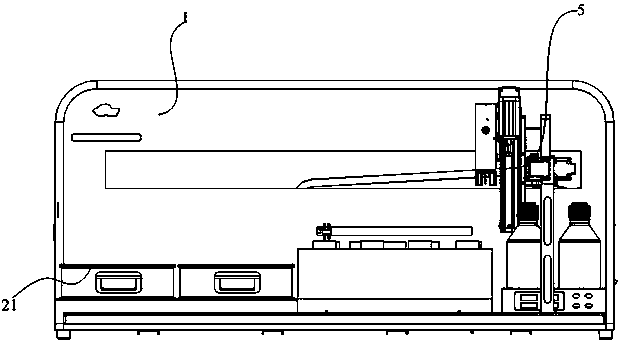

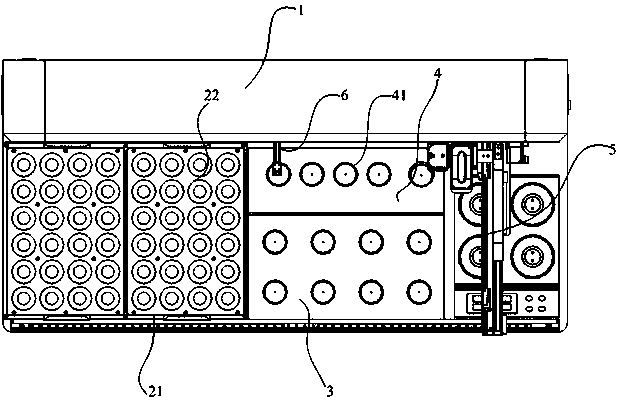

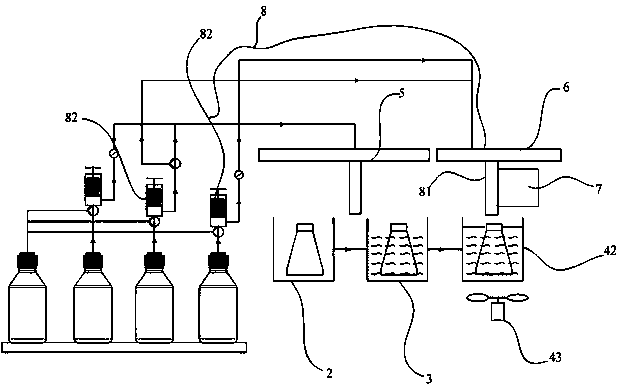

[0024] The technical scheme of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The present invention provides a permanganate index analyzer. Figure 1-3 As shown, it includes the base 1. As the basis of the entire device, it is the carrier substrate of the entire device. The controller is mainly used for communication between various electronic components, receiving or sending signals to each electronic component, and realizing communication with each electronic component. Information interaction between each other and sending signals to each electronic component to control its further actions. Further, in this embodiment, a human-computer interaction system can also be provided, which is connected to the controller to realize control and signal transmission and display.

[0025] Specifically, in this embodiment, the sample area to be tested 2, the water bath heating and digestion area 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com