Clutch devices

A clutch device and clutch technology, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as inability to prevent wandering and inability to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

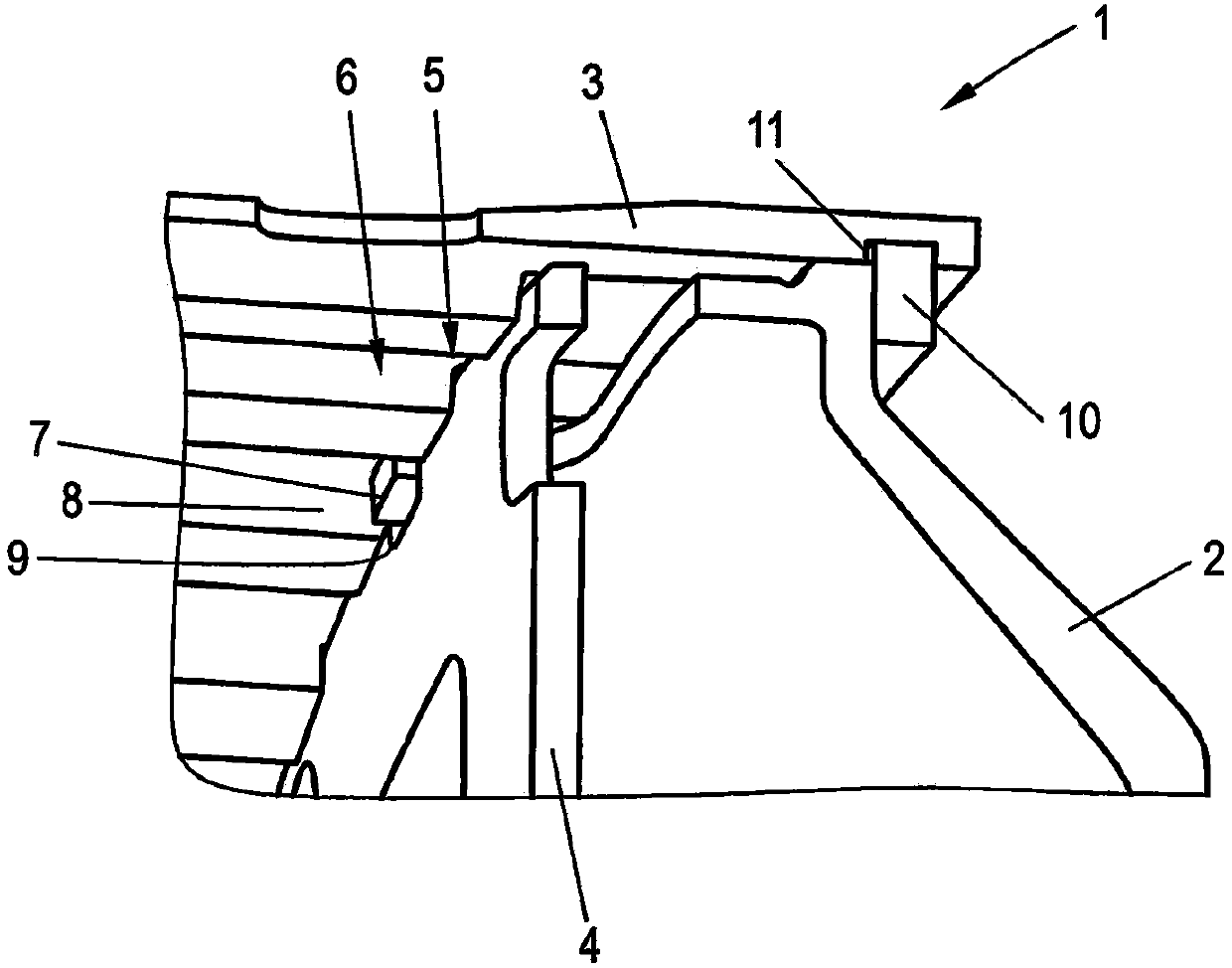

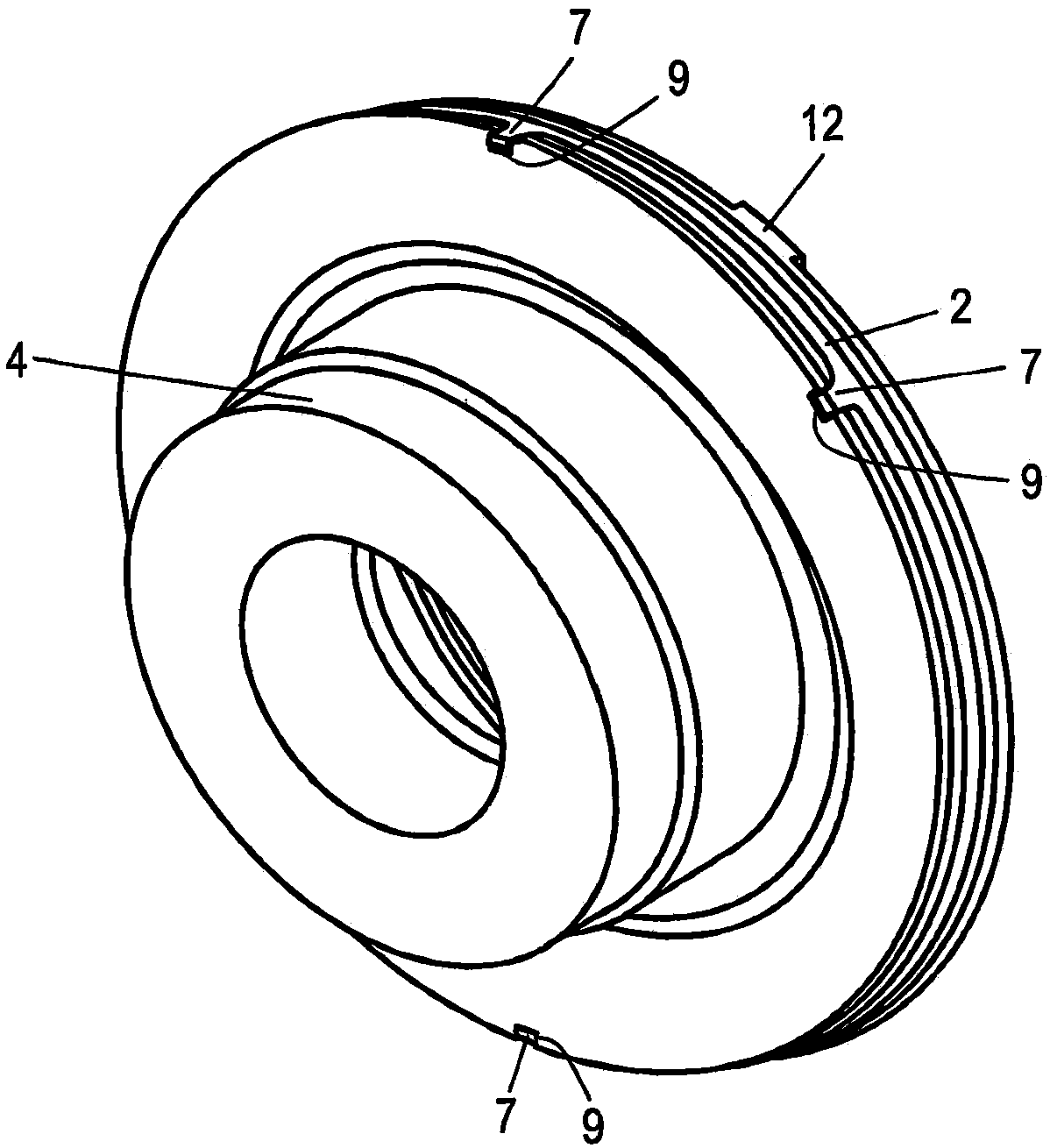

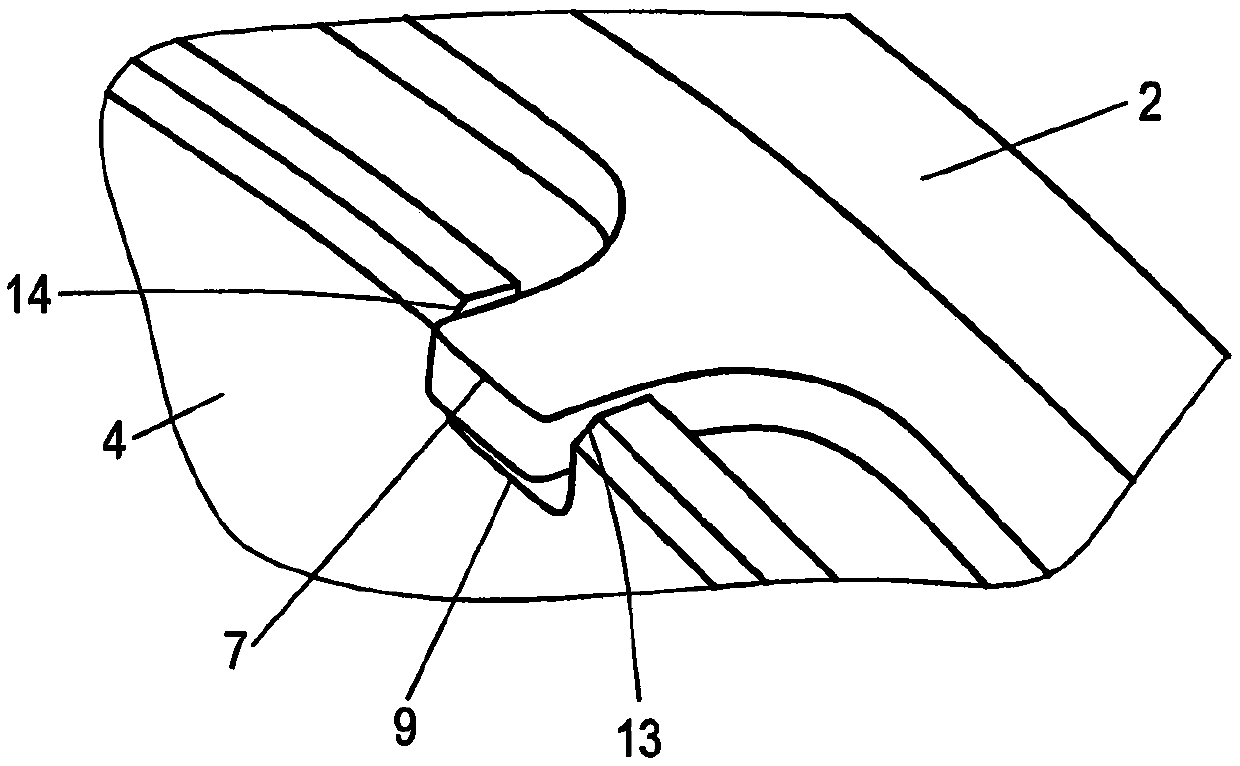

[0030] figure 1 A clutch device 1 is shown, comprising a clutch cover 2 and an outer clutch plate carrier 3 . The outer clutch plate (not shown) is assigned to the outer clutch plate carrier 3 and forms a clutch plate pack with the inner clutch plate (not shown) of the inner clutch plate carrier. Furthermore, a spring support element 4 is formed which has a toothing 5 which cooperates with a toothing 6 of the outer clutch carrier 3 . According to this embodiment, the clutch cover 2 has a first connecting element 7 which fits into a second connecting element 8 of the outer clutch plate carrier 3 . According to figure 1 In the exemplary embodiment shown in , the first connecting element 7 is formed integrally with the clutch cover 2 as a finger protruding from the clutch cover. The second connecting element 8 of the outer clutch carrier is formed by the toothing 6 of the outer clutch carrier. The first connecting element 7 of the clutch cover 2 fits into a corresponding toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com