Winding mechanism for pulling adhesive tape

A sticky tape and sticky tape technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as uneven pulling force by manpower, performance that cannot meet the design requirements, and difficulty in guaranteeing the quality of sticky tapes, etc. , to achieve the effect of improving work efficiency and sticky tape quality, concise structure, and easy design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

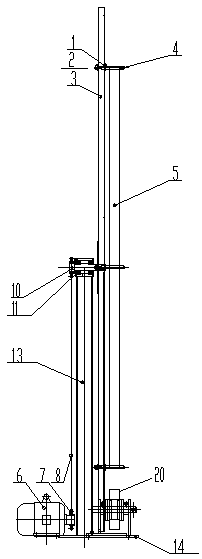

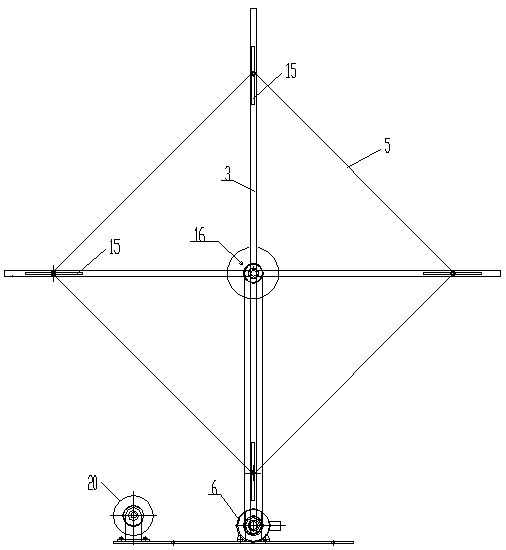

[0024] Accompanying drawing is a kind of embodiment of the present invention.

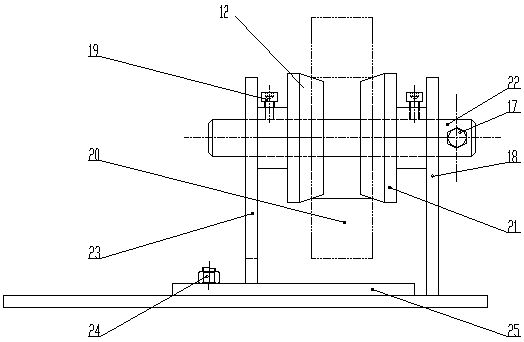

[0025] The adhesive tape winding mechanism of the present invention includes a frame, and a motor 6, a transmission device and a winding device installed on the frame and sequentially connected, and also includes an adhesive tape taking device installed on the frame;

[0026] The rack is fixed on the ground;

[0027] Winding device comprises cross support 3, and the intersection of cross support is connected transmission device, and a strut 4 is all installed on the four arms of cross support, and four struts form the four corners of a square, and the sticky tape that disc adhesive tape 20 emits follows The rotation of the cross bracket is wound on a square formed by four struts, and the adhesive tape is wound into an annular adhesive tape 5 with a certain thickness and a suitable size;

[0028] The adhesive tape taking device adopts an adhesive tape reel support frame, and the disc adhesive tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com