Automatic box sealing gripper for robot

A robot and box-sealing technology, applied in the direction of manipulators, packaging, chucks, etc., can solve the problems of large space occupation, low work efficiency, complex system, etc., and achieve the effect of saving the space occupied by the device, easy operation and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

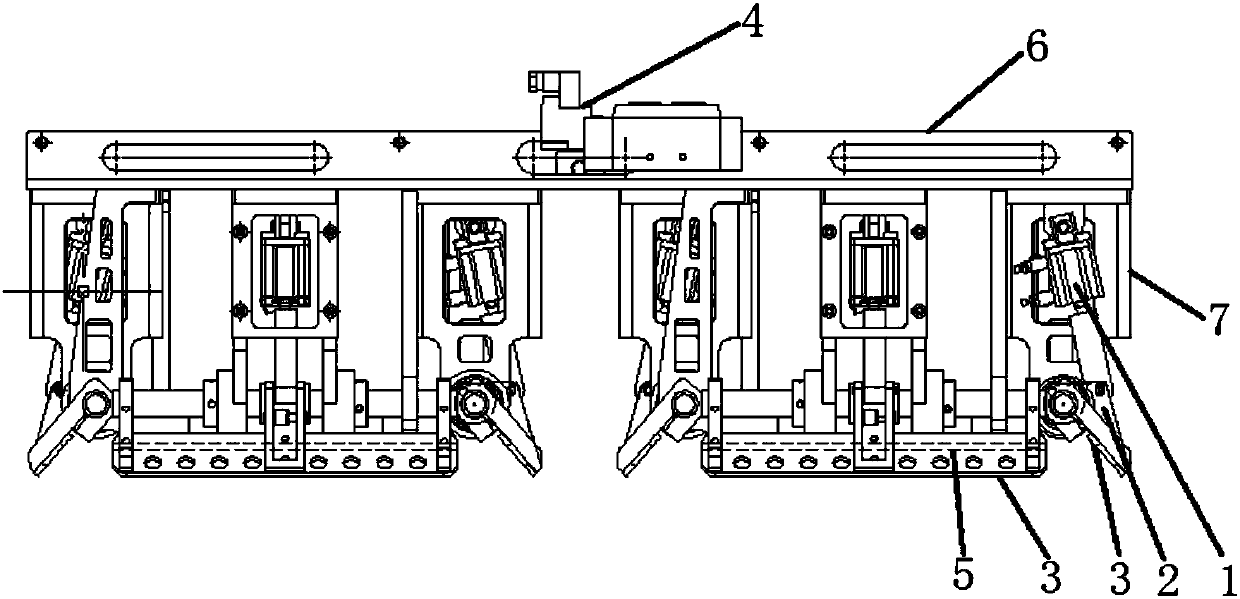

[0025] like Figure 1-2 The shown automatic box-sealing gripper for a robot is arranged at the end of the robot arm 4, and the gripper includes a gripper connecting frame 6 arranged at the end of the robot arm 4 and a pair of symmetrically arranged gripper joints. The four-side sealing unit at both ends of the bottom of the frame 6, the four-side sealing unit simultaneously seals the front, rear, left and right sides of the carton. The four-sided box sealing unit includes a pressing plate 5 arranged at one end of the bottom of the handle connecting frame 6 and four cylinder sealing mechanisms evenly arranged around the pressing plate 5 . The cylinder sealing mechanism comprises a support 7 arranged at the bottom of the handle connecting frame 6, a cylinder 1 arranged at the top of the support 7, and a box sealing plate 3 arranged at the bottom of the support 7 and hinged with the support 7. The sealing plate 3 is connected to the cylinder 1. piston drive connection. A connec...

Embodiment 2

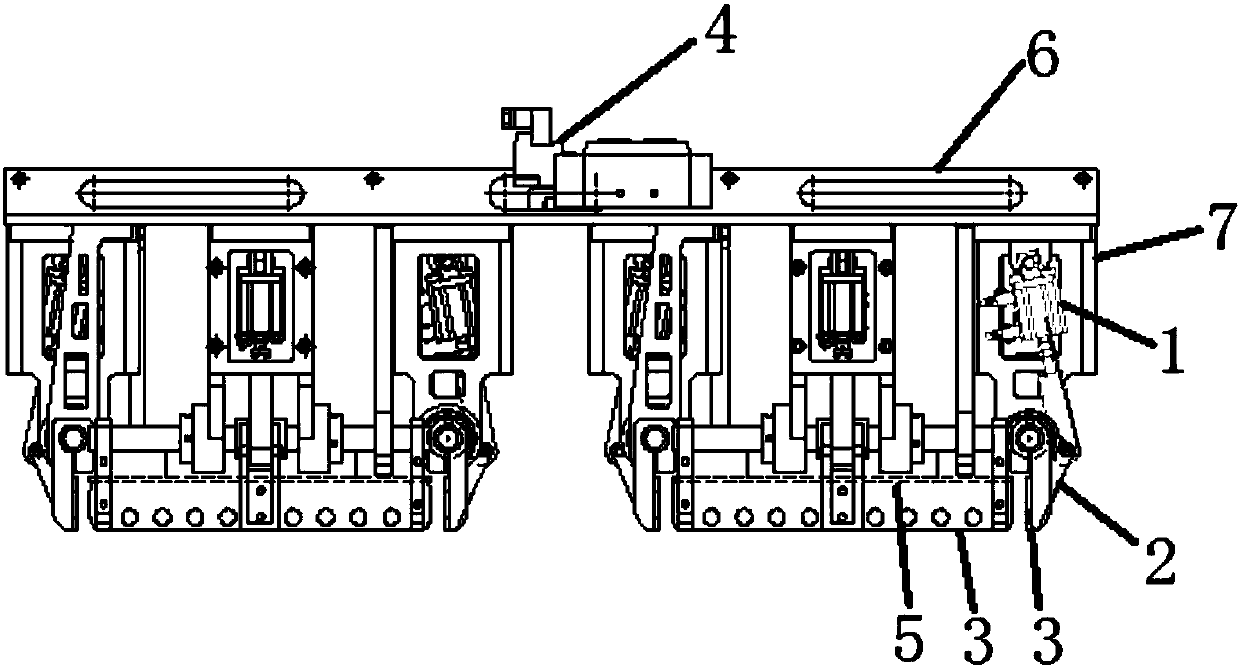

[0029] An automatic box-sealing gripper for a robot, the gripper is arranged at the end of the robot arm 4, and the gripper includes a gripper connecting frame 6 arranged at the end of the robot arm 4 and a four-sided seal arranged at the bottom of the gripper connecting frame 6 Box unit, the four-side sealing unit seals the front, back, left and right sides of the carton at the same time. The four-sided box sealing unit includes a pressing plate 5 arranged at the bottom of the handle connecting frame 6 and four cylinder sealing mechanisms evenly arranged around the pressing plate 5 . The cylinder sealing mechanism comprises a support 7 arranged at the bottom of the handle connecting frame 6, a cylinder 1 arranged at the top of the support 7, and a box sealing plate 3 arranged at the bottom of the support 7 and hinged with the support 7, the sealing plate 3 and the cylinder 1 piston drive connection. Cylinder 1 is hinged with support 7. A pressure plate support rod is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com