Method for controlling condensate gas reservoir mist retrograde condensation

A technology for condensate gas reservoirs and control methods, which is applied in the field of foggy reverse condensate control in condensate gas reservoirs, can solve the problems of large investment and low condensate oil recovery, and achieve high recovery and good recovery Condensation effect, reduce the effect of anti-condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

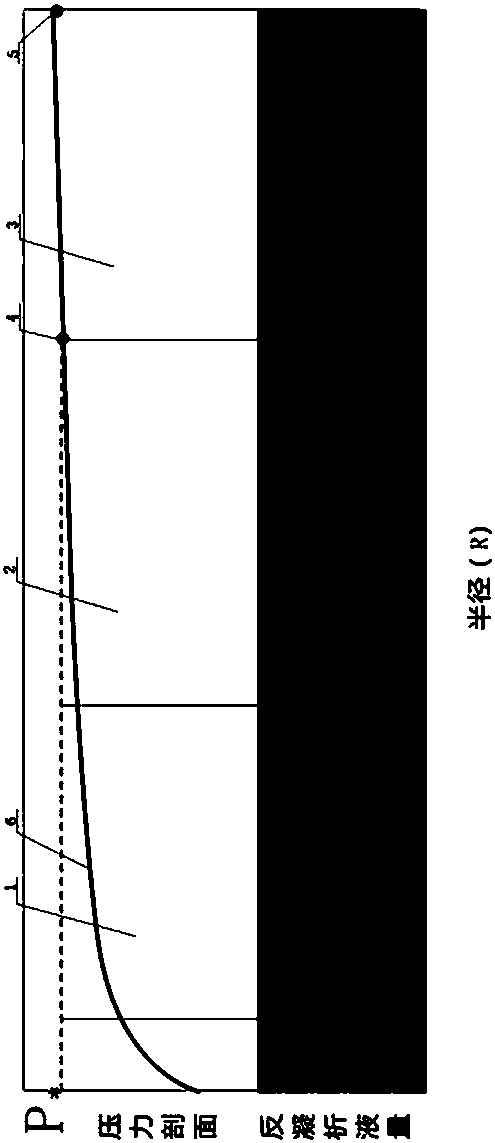

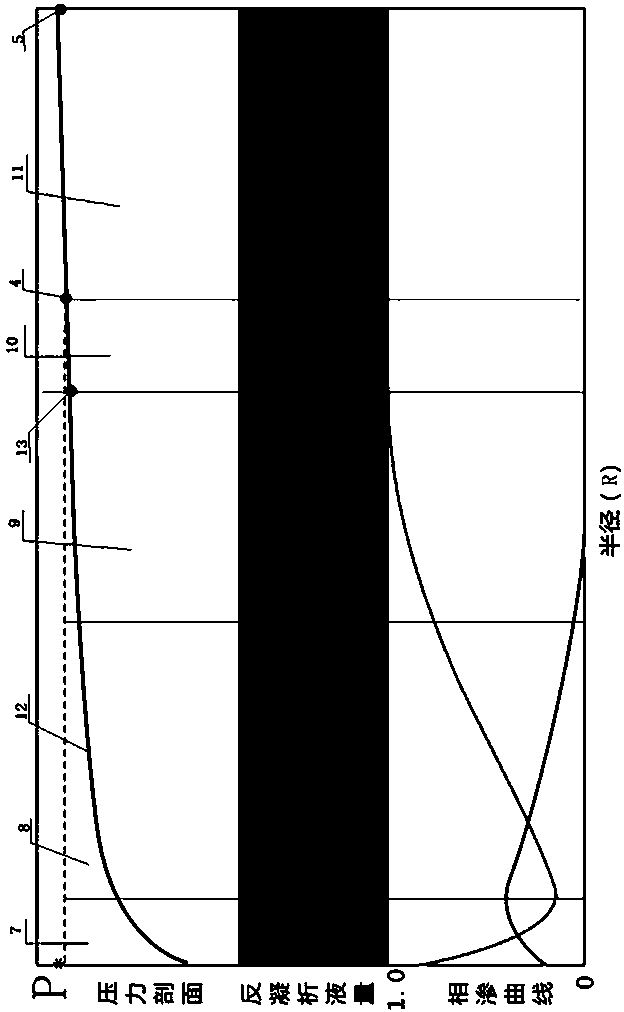

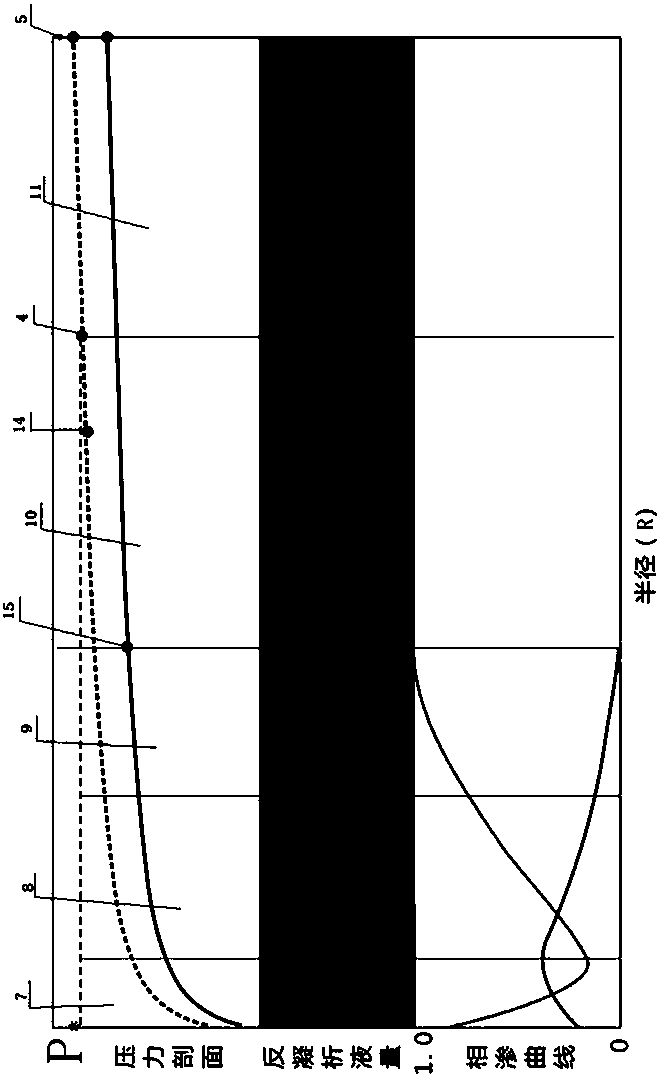

[0027] Embodiment 1: The control method of foggy reverse condensate in the condensate gas reservoir is controlled according to the following method: the gas production rate is 3% to 8%, the well spacing is 400m to 1400m, and the production pressure difference is 0.5MPa to 2.2 MPa.

[0028] Through the control of gas production speed, well spacing and production pressure difference, it is possible to control the reverse condensate oil in the gas reservoir to always be in the form of mist (dispersion), and to form and recover at any time, so as to achieve foggy reverse condensate and foggy reverse condensate Oil flow output, reduce retrocondensation.

[0029] Since the method of the present invention is not a development method of gas injection and pressure maintenance, there is no need to build corresponding gas injection supporting facilities, so that no corresponding investment funds are required. The method requires less investment.

[0030] There are three control paramet...

Embodiment 2

[0036] Embodiment 2: The control method of misty retrocondensation in the condensate gas reservoir is controlled according to the following method: the gas production rate is 3% or 8%, the well spacing is 400m or 1400m, and the production pressure difference is 0.5MPa or 2.2 MPa.

Embodiment 3

[0037] Embodiment 3: As an optimization of the above embodiment, when the gas reservoir is a high-porosity and high-permeability condensate gas reservoir, the well spacing of vertical wells is 900m to 1250m, and the well spacing of horizontal wells is 1300m to 1400m.

[0038] For condensate gas reservoirs in high-porosity and high-permeability reservoirs, the vertical well spacing and horizontal well spacing are set so that the control ranges of each well overlap and can realize foggy reverse condensation in condensate gas reservoirs in high-porosity and high-permeability reservoirs. Reduce the occurrence of retrocondensation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com