Double-layer liquid-transferring gun frame

A pipette rack and double-layer technology, applied in the field of pipette racks, can solve the problems of large footprint, corrosion, waste of space, etc., and achieve the effect of flexible and convenient use and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

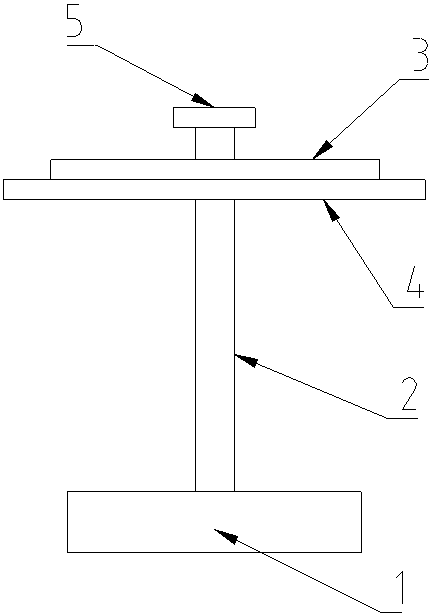

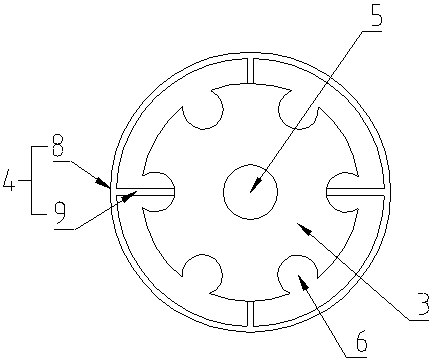

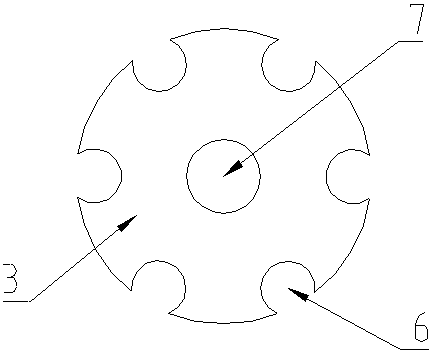

[0023] Embodiment 1, the base 1 and the bottom end of the telescopic support column 2 are connected by rotation. At this time, the telescopic support column 2 and the upper gun frame seat 3 are of an integrated structure, and the telescopic support column 2 and the lower layer of the gun frame seat 4 are integrated. Structure, that is, the telescopic support column 2 can rotate on the base 1, and the telescopic support 2 rotates to drive the upper gun rack seat 3 and the lower gun rack seat 4 to rotate, and the telescopic support column 2 is connected to the upper gun rack seat 3 and the lower gun rack seat 4 respectively. The pedestal 4 is set as an integrated structure, which can be more durable; in addition, the rotating connection structure between the base 1 and the telescopic support column 2 can be realized through various implementation methods, which are not described here. Specifically defined, among them, the rotating structure is preferably a self-locking rotating s...

Embodiment 2

[0024] Embodiment 2: The upper gun rack seat 3 is connected in rotation with the telescopic support column 2, and the gun rack seat 4 in the lower layer is connected in rotation with the telescopic support column 2. At this time, the bottom ends of the base 1 and the telescopic support column 2 are fixedly connected to the Together and as an integrated structure, that is, the upper gun rack seat 3 and the lower gun rack seat 4 can rotate independently with the central axis of the telescopic support column 2 as the rotation axis, while the base 1 and the telescopic support column 2 are fixedly connected structure, and at this time it is preferred to set the base 1 and the telescopic support column 2 as an integrated structure, which can make the whole device more stable and durable; The rotating structure between the gun rack seat 4 and the telescopic support column 2 can be realized through various implementation methods, and is not specifically limited here. Among them, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com