Drilling machine capable of controlling depth of crack-arresting holes in process of repairing cracks of steel box girder

A technology for drilling depth and steel box girder, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, measurement of positioning in boring machine/drilling machine, etc. It can solve the problems of precise control of drilling depth and achieve easy disassembly with the effect of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

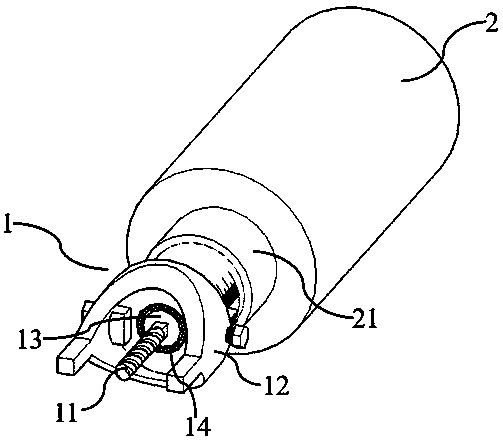

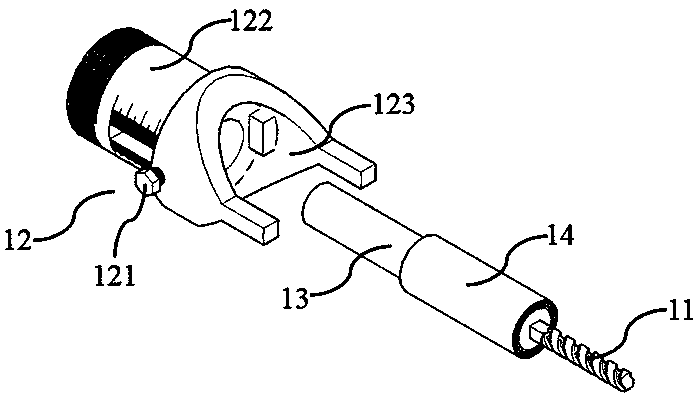

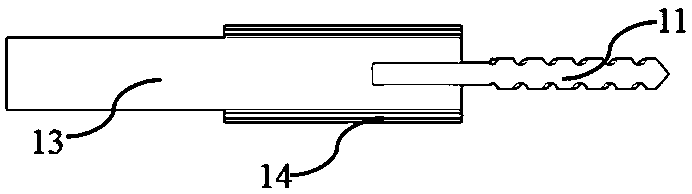

[0025] The steel box girder crack repairing drilling machine that can control the depth of drilling crack hole in this embodiment is as follows: Figure 1-Figure 4 As shown, it includes a drilling device 1 and a drilling machine body 2 . The drilling device 1 mainly includes a drill bit 11 , a drilling depth control device 12 , a transmission shaft 13 and a roller bearing 14 . One end of the transmission shaft 13 is connected to the internal driving device of the drilling body 2, and the other end is connected to the drill bit 11; the drilling depth control device 12 is sleeved on the periphery of the transmission shaft 13 through the roller bearing 14, and is connected to the drilling body through the threaded port. 2 connections.

[0026] One end of transmission shaft 13 is connected with the driving device inside the drilling body 2, and the other end then offers a square clamping hole for installing the required drill bit 11 for drilling.

[0027] The drilling depth cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com