LED display suite

A technology of LED display screen and LED lamp, which is applied in the direction of instruments, identification devices, etc., can solve the problems of large quantity of screws and nuts, inconvenient operation, high cost, etc., and achieve the effect of reducing labor intensity, saving cost, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

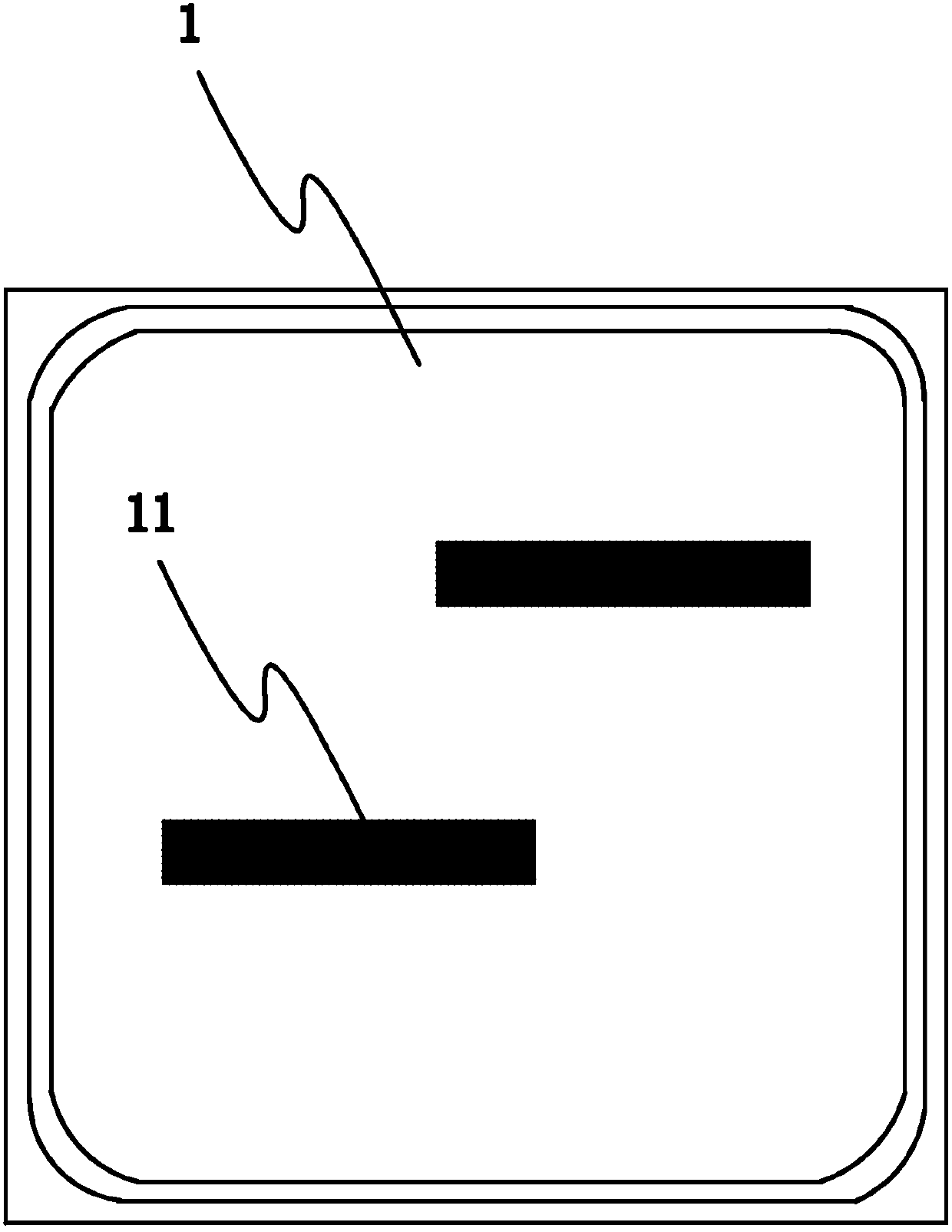

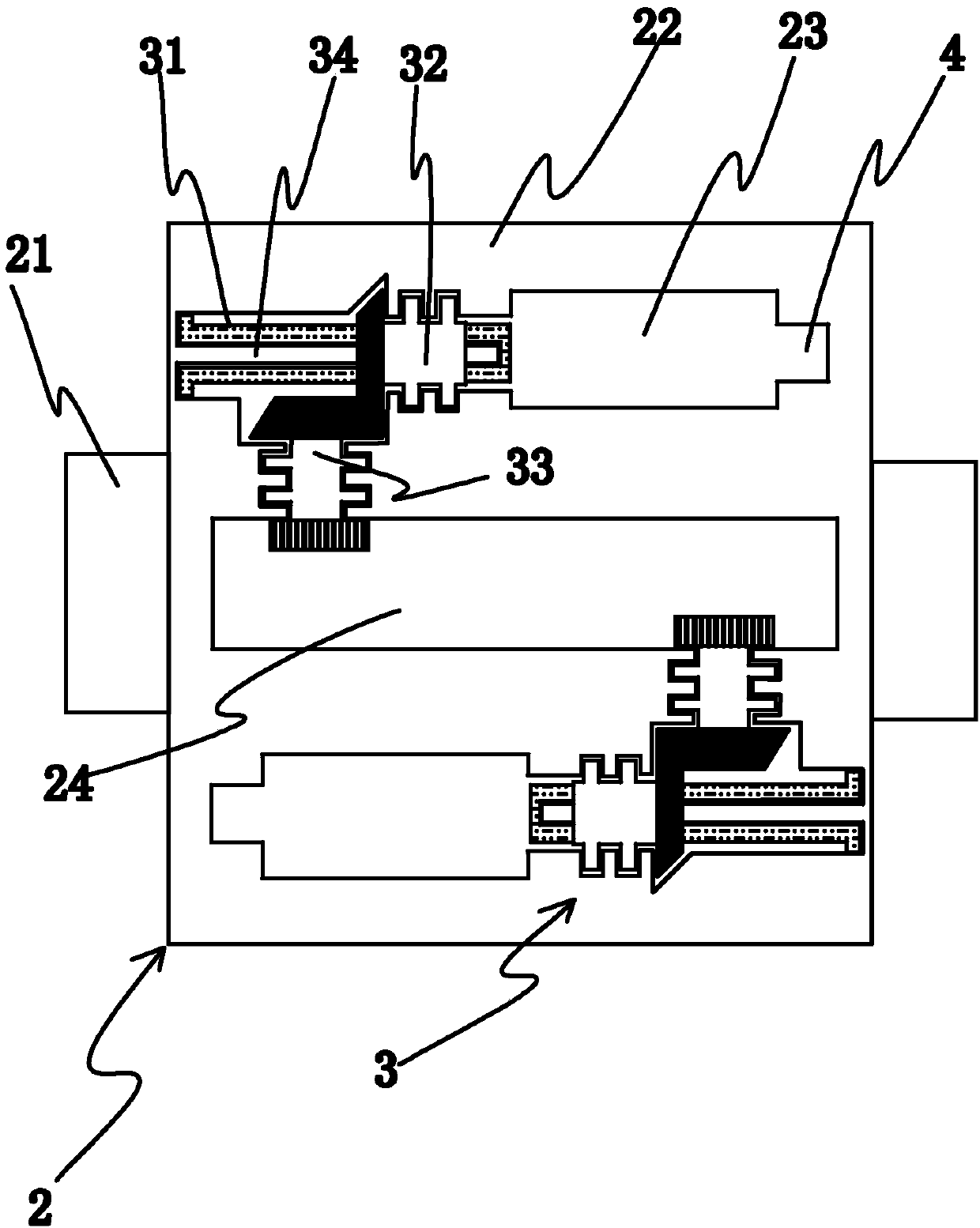

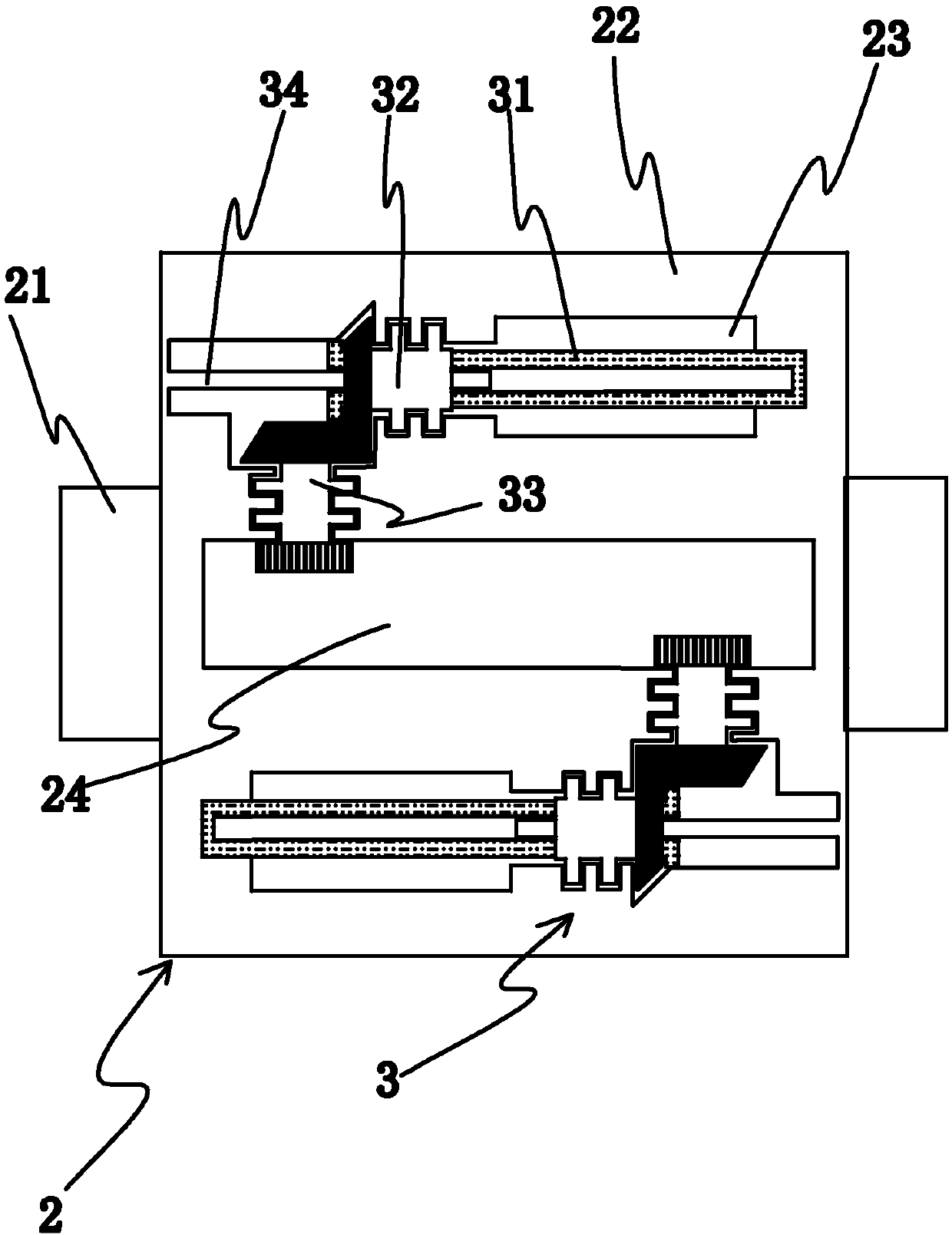

[0021] refer to Figure 1 to Figure 5 , the embodiment of the present invention discloses an LED display kit, comprising a bottom case 1, an LED cover with mounting holes for LED lamps uniformly distributed on the surface of the bottom case, and a fixing frame 2 for fixing and installing the bottom case , the bottom shell 1 is arranged with locking shafts 11 arranged in sequence along the height direction, the locking shafts 11 are provided with shaft holes along the axial direction, and the adjacent locking shafts 11 are arranged in a dislocation distribution;

[0022] The fixed frame 2 includes a fixed base 21, the fixed base 21 is provided with a fixed bracket 22, the fixed bracket 22 is adapted to the shape of the bottom shell, and the fixed bracket 22 is provided with a locking shaft embedded The locking shaft holes 23; the fixed bracket 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com