Pressure sensor test system

A pressure sensor and test system technology, applied in the direction of force/torque/work measuring instrument calibration/testing, instruments, measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

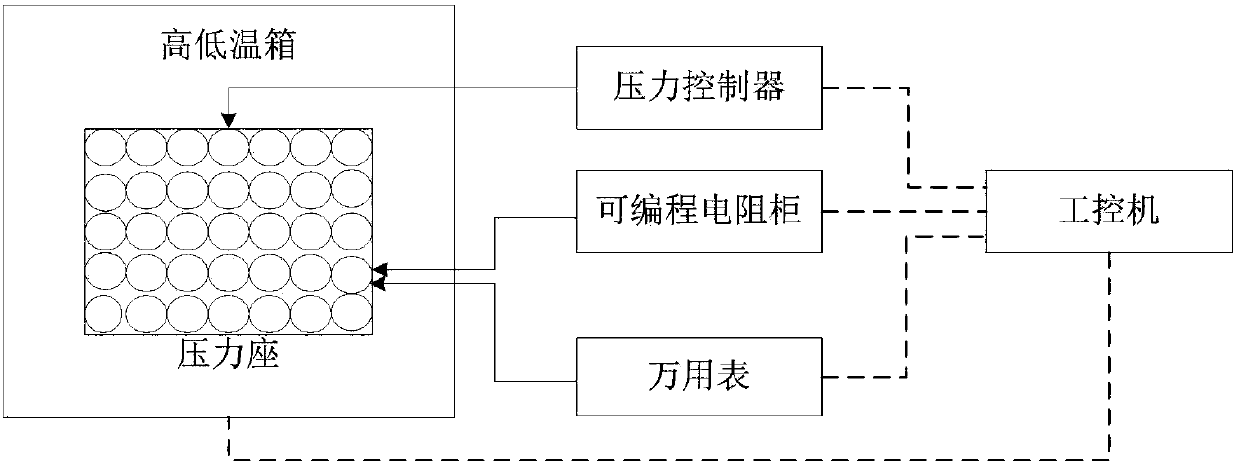

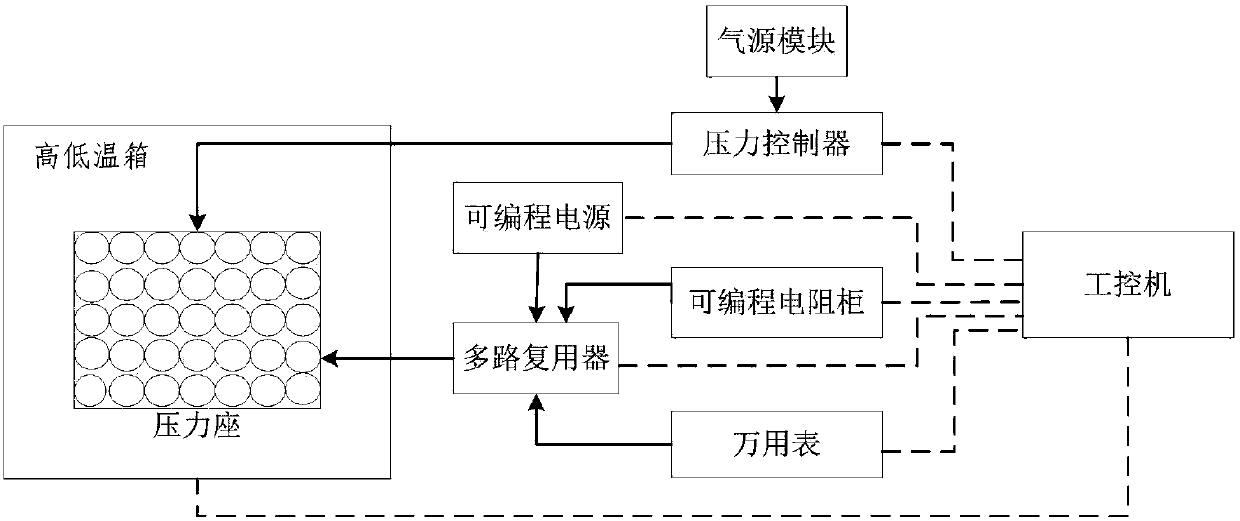

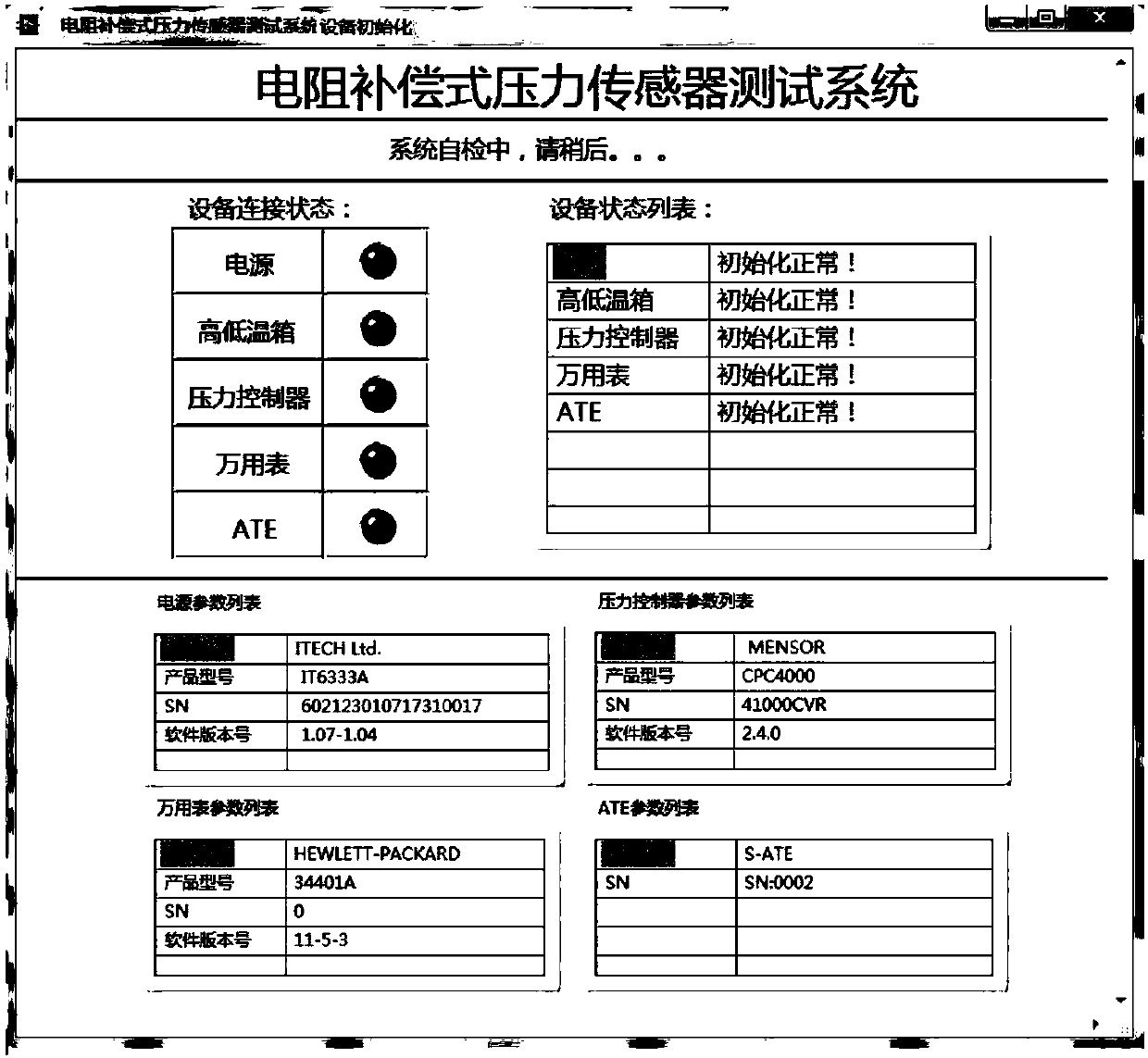

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] Pressure is one of the most basic parameters for measurement and control in production processes and scientific experiments. Pressure sensors become important components for measuring pressure, and can convert pressure into electrical signals through certain rules. It is widely used in In the production and scientific research of industry, petroleum, chemical industry, biomedicine, navigation, aerospace, aviation and other fields. The reliability of the pressure sensor is very important. It is directly related to the performance of the system using the sensor, affects the quality and speed of production and construction, and even brings serious personal safety probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com