Motor fan heat dissipation hub structure and cooling fan composed of same

A cooling fan and fan wheel technology, applied in the direction of engine cooling, cooling/ventilation devices, electromechanical devices, etc., can solve the problems of high temperature of the motor, affecting the performance of the motor, heat generation and temperature rise, etc., to increase the air flow speed and Effect of air flow and emission efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

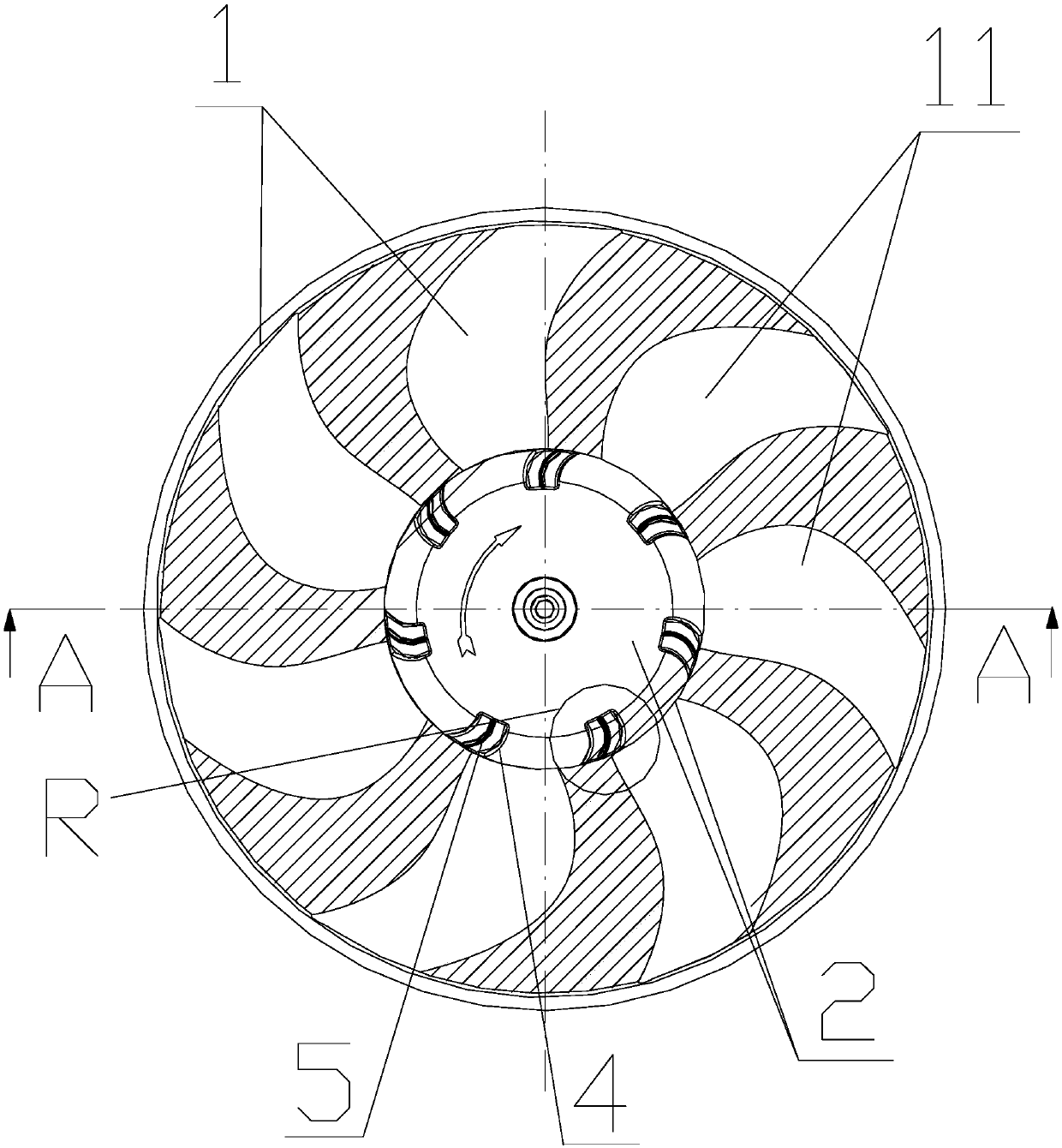

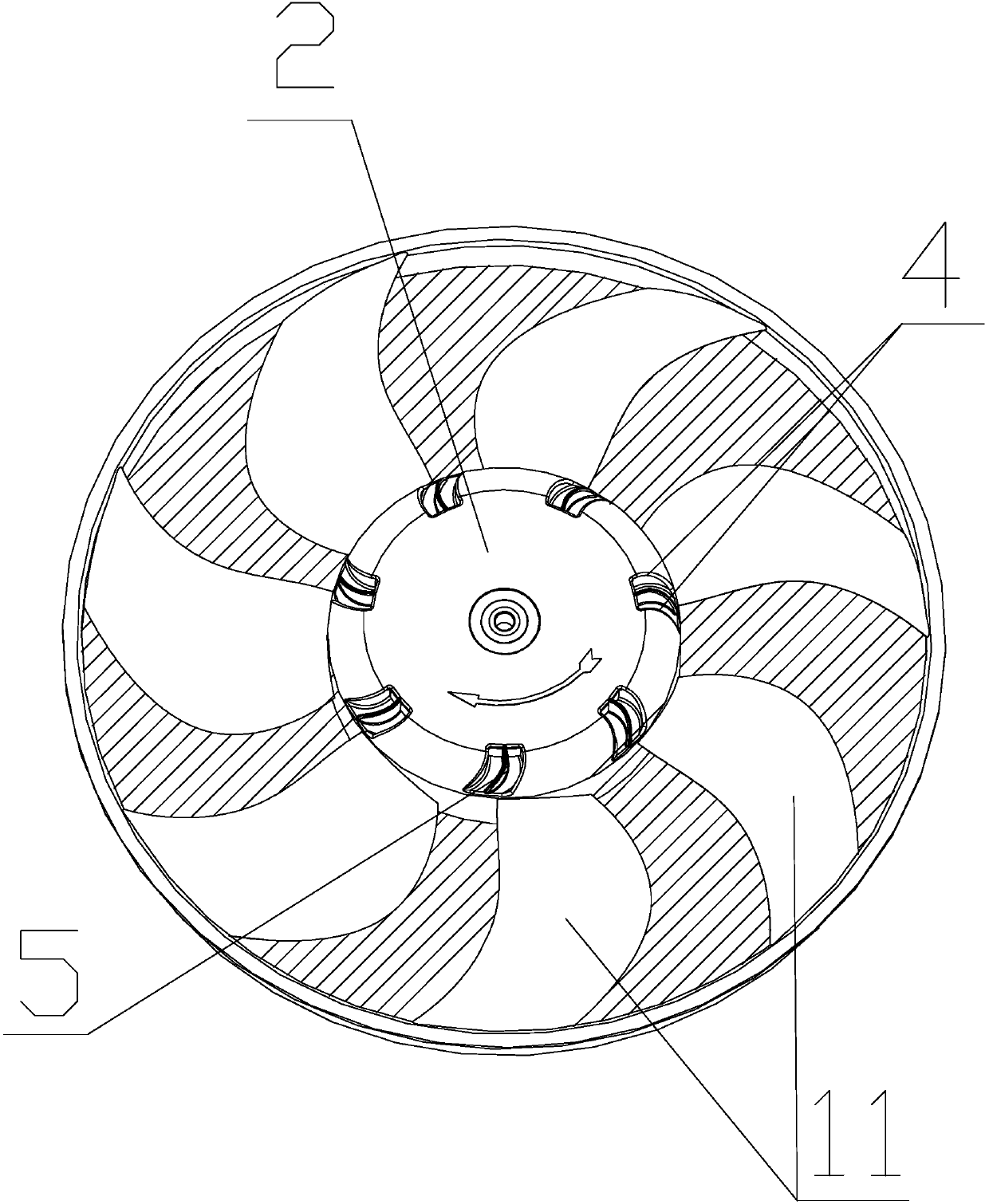

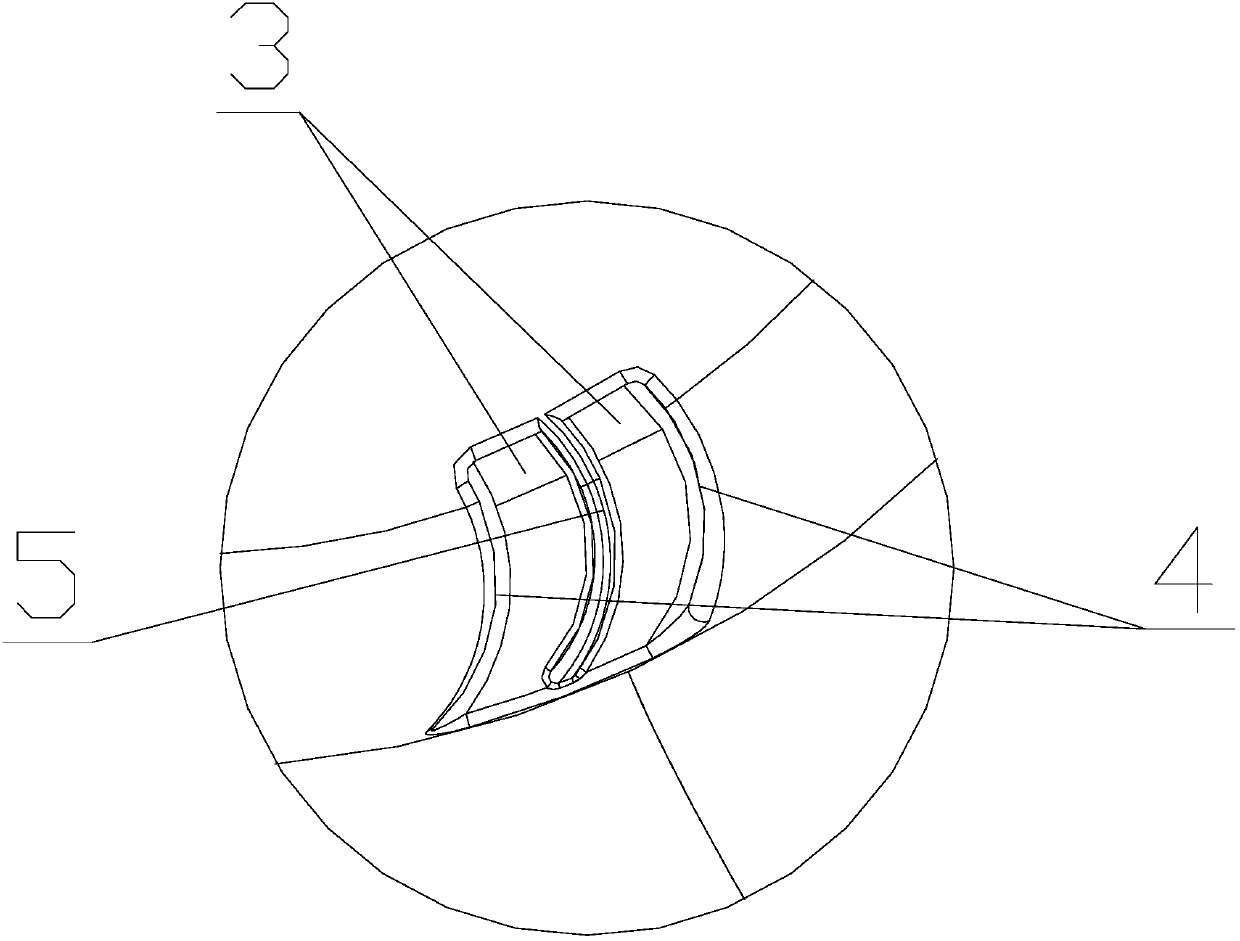

[0027] Such as Figure 1 ~ Figure 3 As shown, a motor fan heat dissipation hub structure includes a fan hub 2, the fan hub 2 has a motor accommodating cavity inside, and the fan hub 2 is provided with several ventilation grooves 4 along the edge, as figure 1 , figure 2 As shown, the preferred fan hub 2 of the present invention is provided with 6-10 ventilation slots 4 evenly distributed along the edge. The fan hub 2 is provided with a ventilation hole 3 corresponding to the ventilation slot 4, and the ventilation slot 4 communicates with the motor accommodation cavity through the ventilation hole 3; the ventilation hole 3 of the present invention is provided correspondingly near the fan hub 2 motor accommodation cavity, such as image 3 As shown, all the ventilation holes 3 of the present invention are close to the center of the motor accommodating cavity (that is, the inside of the ventilation groove 4 away from the outer edge of the fan hub 2). At least one vane 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com