Laying method for waterproof plates in tunnel

A technology of tunnel waterproof board and laying method, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as difficult detection and inspection of water leakage holes, limitation of waterproof board width, and welding scars of waterproof boards, so as to reduce hidden dangers of water leakage, Reduce the workload and eliminate the effect of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

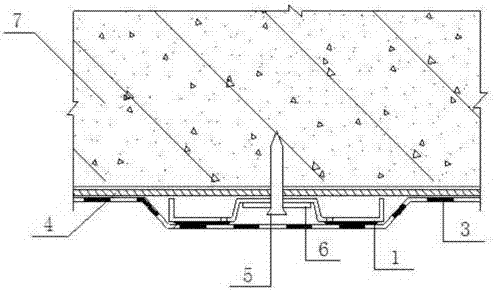

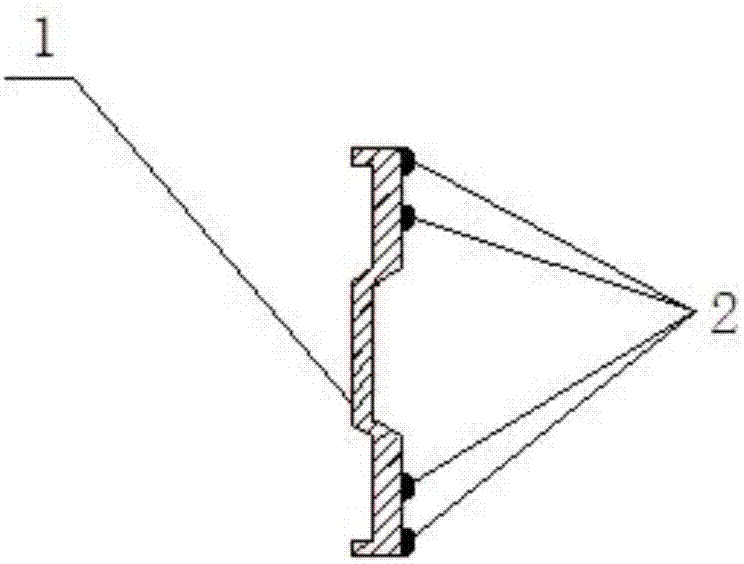

[0039] Such as figure 1 and figure 2 As shown, the invention provides a method for laying a tunnel waterproof board, comprising the steps of:

[0040] Step 1. Treat the base surface of initial support 7

[0041] Remove the exposed bolt head and steel mesh head on the base surface of the initial support 7 at the same root, and smooth it with cement mortar. For the concave and convex parts on the surface of the initial support, select supplementary spraying concrete and plaster mortar according to the size of the leveling range 1. The method of partially hanging the molded concrete is leveled to prevent the local unevenness of the waterproof board from being pulled when the concrete is poured;

[0042] Step 2. Laying geotextile 4

[0043] The geotextile 4 is laid on the base surface of the initial support 7, and the geotextile 4 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com