Cleaning system of photovoltaic panels of solar power station and arrangement method therefor

A clean system and photovoltaic panel technology, applied in the field of solar photovoltaic power generation, can solve the problems of low customer assembly willingness, high installation cost, and affecting the power generation efficiency of photovoltaic modules, so as to improve the level of automation management and reduce investment and operation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

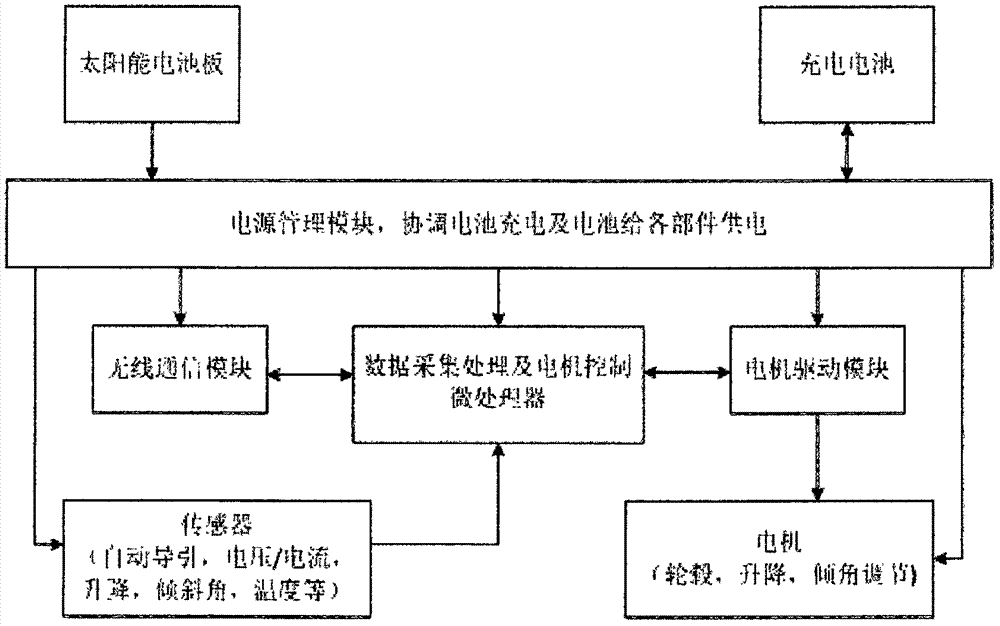

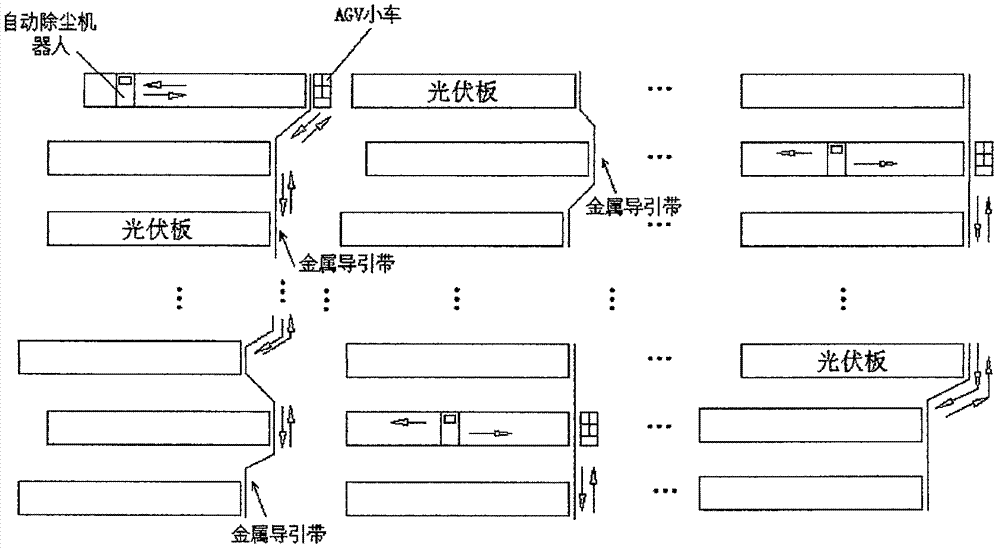

[0026] In order to adapt to the daily cleaning and maintenance of solar power station photovoltaic panel components arranged in various complicated situations, the present invention provides a cleaning system for solar power station photovoltaic panels, which does not need to be configured one by one, which significantly reduces the cost of input and operation. The specific structure is as follows figure 1 with figure 2 shown. The cleaning system is mainly composed of an automatic dust removal robot responsible for cleaning the photovoltaic panel components and an AGV trolley that transports the automatic dust removal robot. Among them, the automatic dust removal robot used to clean the photovoltaic panel assembly has many structures in the prior art, and any device that can realize the automatic cleaning function of the photovoltaic panel assembly can be applied to the cleaning system provided by the present invention, so the present invention The invention does not explain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com