Double-rod pressing strip fixer

A fixer and beading technology, which is applied in the field of double-rod beading fixers, can solve problems such as: the wooden pile will be pulled up by the branches of the mother plant in rainy days, the beating operation process is laborious and time-consuming, and it will affect the germination of buds on the branches, etc. Achieve the effects of shortening the production cycle of seedlings, saving labor time and funds, and facilitating promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

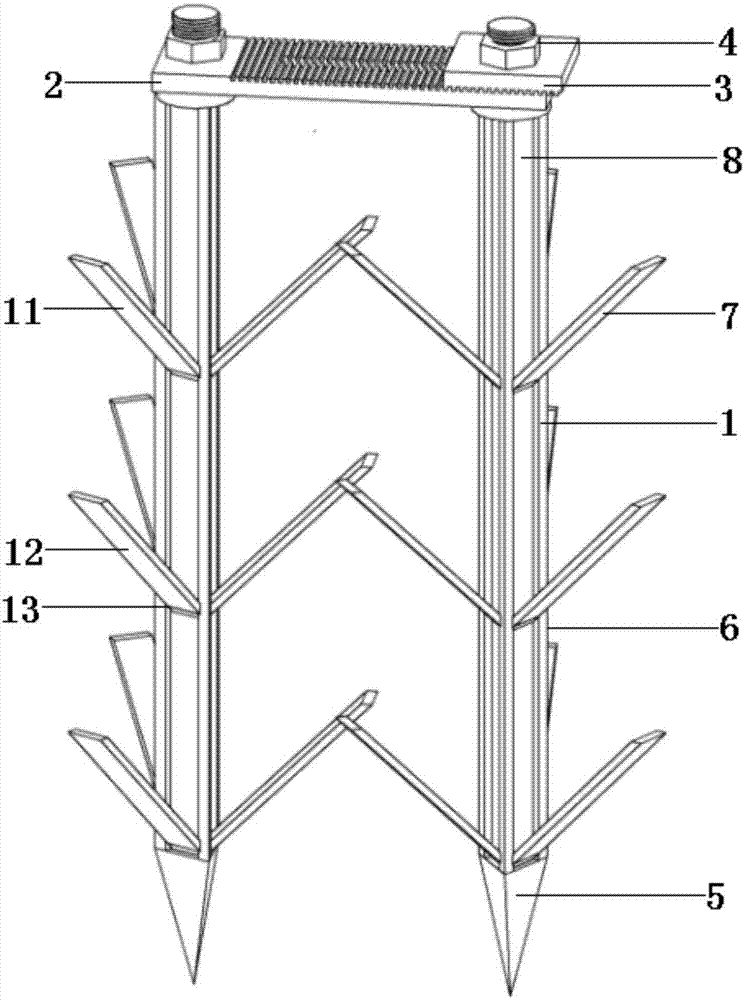

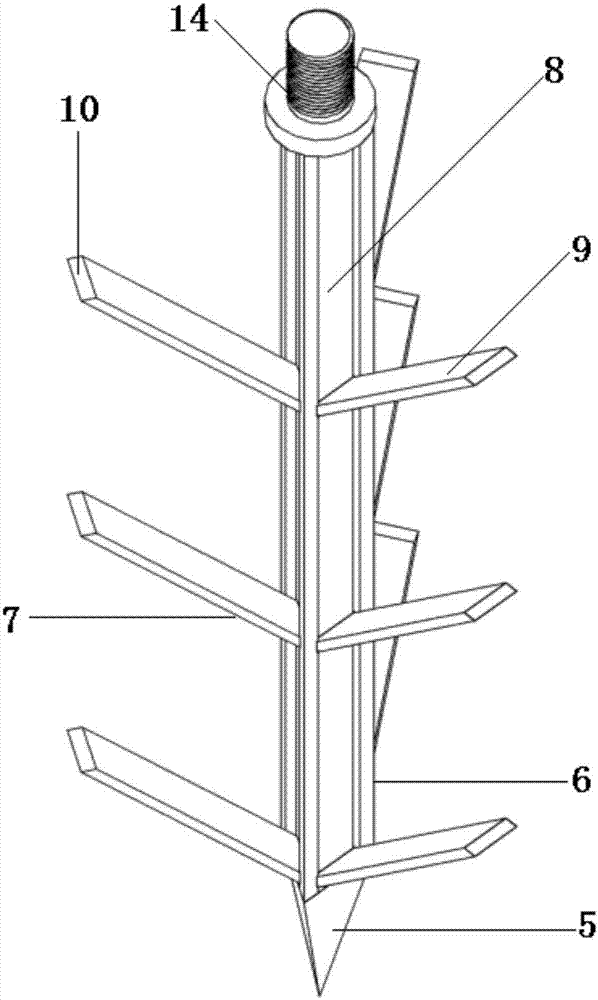

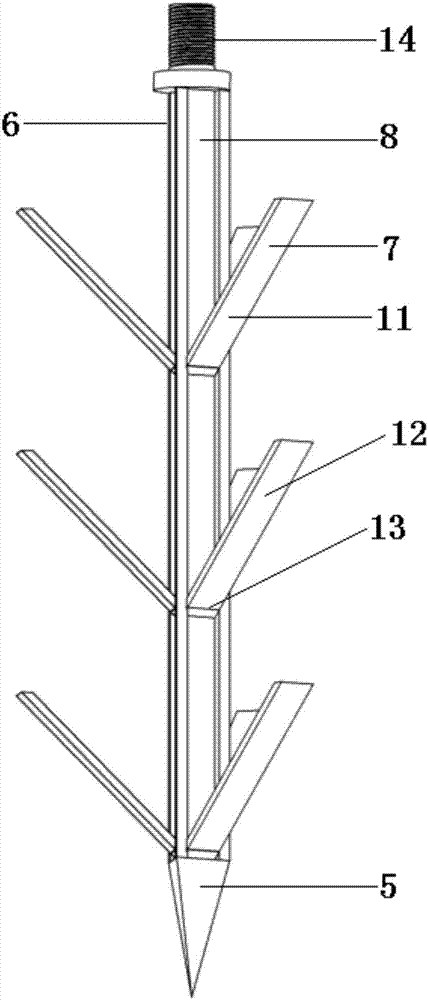

[0030] As another embodiment of the present invention, the rod tip 5 is in the shape of a regular triangular pyramid, and this kind of rod tip 5 is most likely to enter the soil.

[0031] As another embodiment of the present invention, every three wing plates 7 surround the fifteenth prism 6 of the shaft, and at the same height, each wing plate 7 is connected to a concave side of the fifteenth prism 6 of the shaft 8; On the same concave side 8 of the 15-prism prism 6 of the shaft, there is a distance between the upper and lower adjacent wing plates 7 . This is beneficial for the wing plate 7 to play a fixing role.

[0032] As another embodiment of the present invention, when the double-rod bead holder stands in the air, the dihedral angle formed by the concave side 8 of the 15-prism prism 6 of the shaft and the inner side 9 of the connected wing plate 7 is 45°. °. The dihedral angle formed by the upper inclined surface 10 of the wing plate 7 and the outer surface 11 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com