Multi-angle supporting bearing

A support bearing, multi-angle technology, applied in sliding contact bearings and other directions, can solve problems such as poor reliability, achieve good compression resistance and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

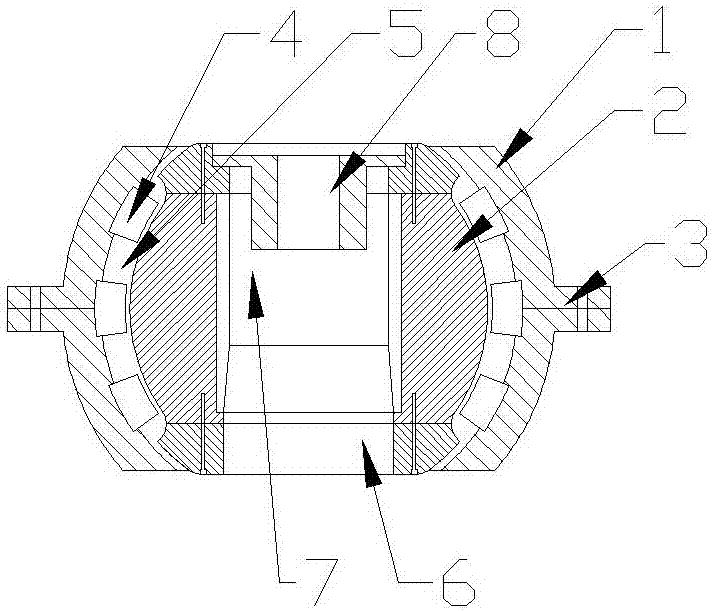

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] Such as figure 1 As shown, the present invention is a multi-angle supporting bearing, including a supporting frame, and a rotating cavity with upper and lower openings is arranged in the supporting frame, and the supporting frame is divided into The upper and lower parts are symmetrical. Two fixing flanges are arranged on the outer wall of the supporting frame corresponding to the separation line of the two parts. The upper and lower parts of the supporting shell are fixedly connected by fixing flanges, and the Screws are fixedly connected, the section of the side wall of the rotating cavity is arc-shaped, and a spherical rotating block is embedded in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com