Spherical carrier roller for material conveying belt

A conveyor belt and spherical technology, which is applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problems of conveyor belt wear and deviation, and achieve the characteristics of not easy to run materials, reasonable force and labor saving, and reduced drag force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

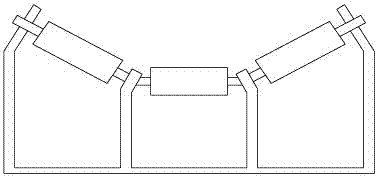

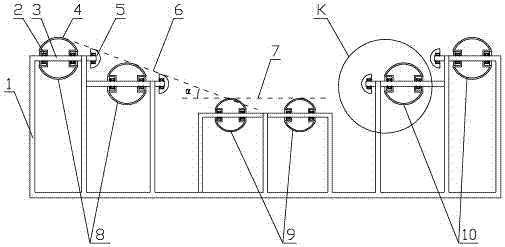

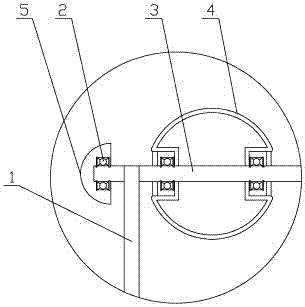

[0023] see figure 2 , image 3 , the present invention is a spherical idler for material conveying belts, which has an idler bracket 1, and the inclined spherical idler group A8, the horizontal spherical idler group B9 and the inclined spherical idler are successively arranged on the idler bracket from left to right. The roller group C10, the inclined spherical idler group A and the inclined spherical idler group C are symmetrically arranged. The inclined spherical idler group A is formed by a number of roller balls 4 arranged from high to low, and the horizontal spherical idler Group B is composed of several idler balls arranged horizontally, inclined spherical idler group C is formed by several idler balls arranged from low to high, and each of the idler balls passes through a roller ball The horizontal main shaft 3 of the center is connected with the roller support, and the roller ball and the horizontal main shaft are connected by the bearing 2. The position of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com