One-way clutch

A technology of one-way clutches and clutches, which is applied to one-way clutches, clutches, mechanical equipment, etc., and can solve problems such as the inability to control the reverse rotation of the output part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The terms or words used in this specification and the scope of the claims should not be limited to the usual or dictionary meanings to be interpreted, but the inventor should consider the best way to explain his own invention and properly define the terms and concepts, and interpret them as meanings and concepts consistent with the technical ideas of the present invention. concept.

[0035] Therefore, the embodiment shown in this description and the structure in the accompanying drawings are only one of the preferred embodiments of the present invention, and cannot represent the technical idea of the present invention. equivalents or modifications.

[0036] Describe in detail below in conjunction with accompanying drawing:

[0037] The one-way clutch of the present invention transmits both the reverse and forward rotational forces of the input part to the output part.

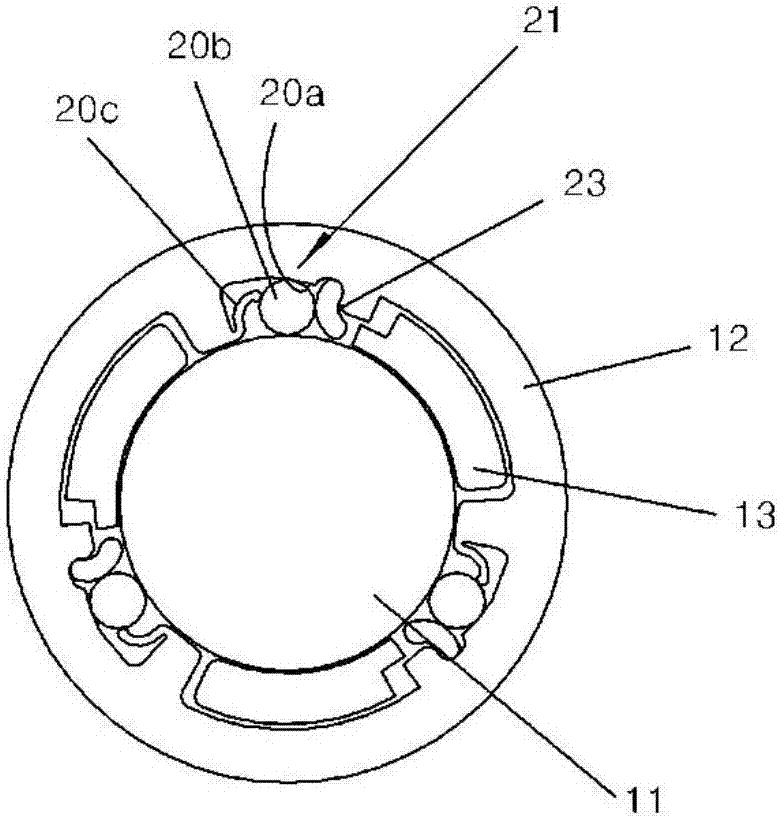

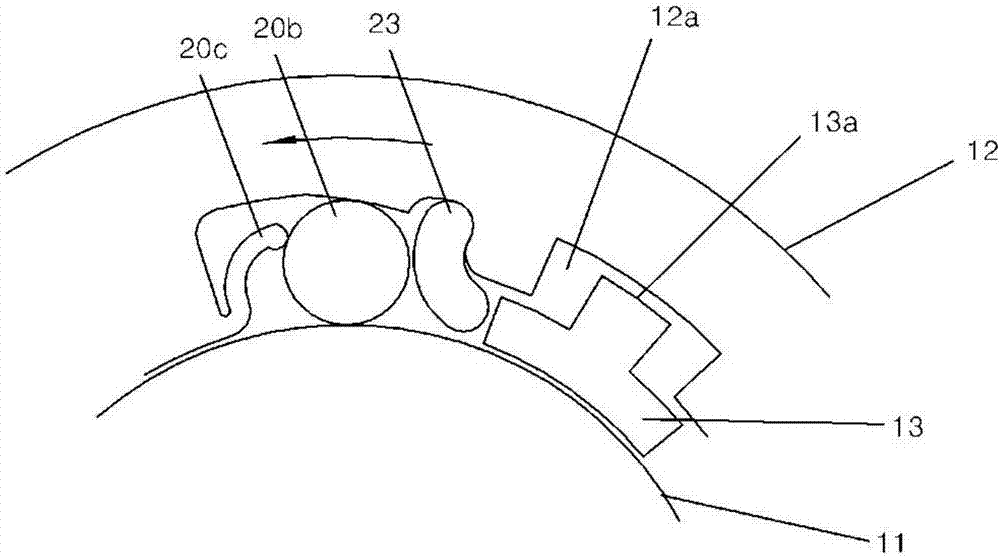

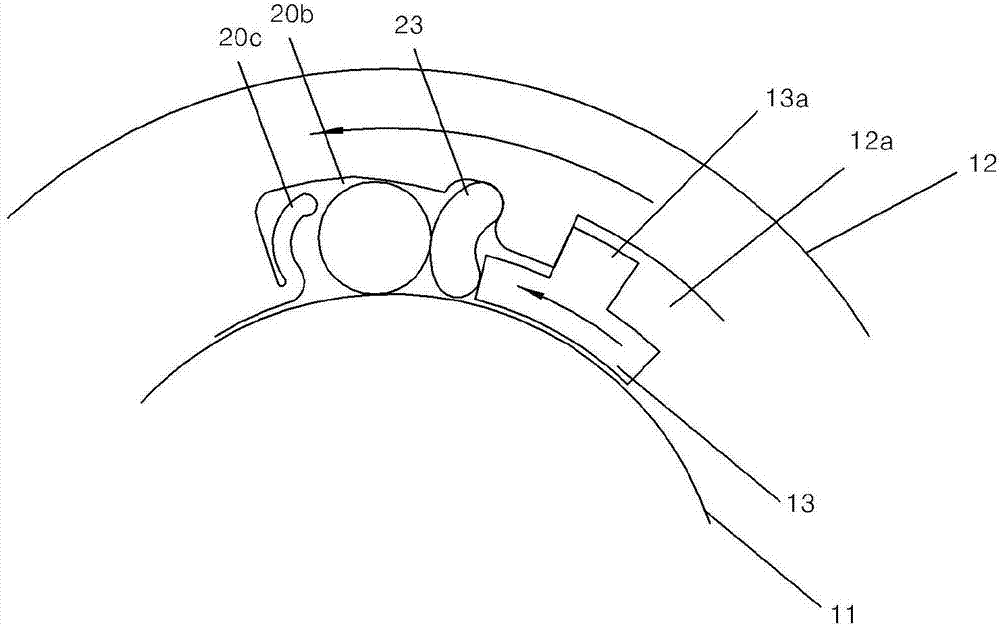

[0038] That is, the one-way clutch of the present invention includes a fixed part 11 located on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com