A method and system for troubleshooting equipment fault components

A technology for equipment failure and components, which is applied in the field of equipment failure component troubleshooting methods and systems, and can solve problems such as waste of time and energy, low efficiency of equipment failure component troubleshooting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

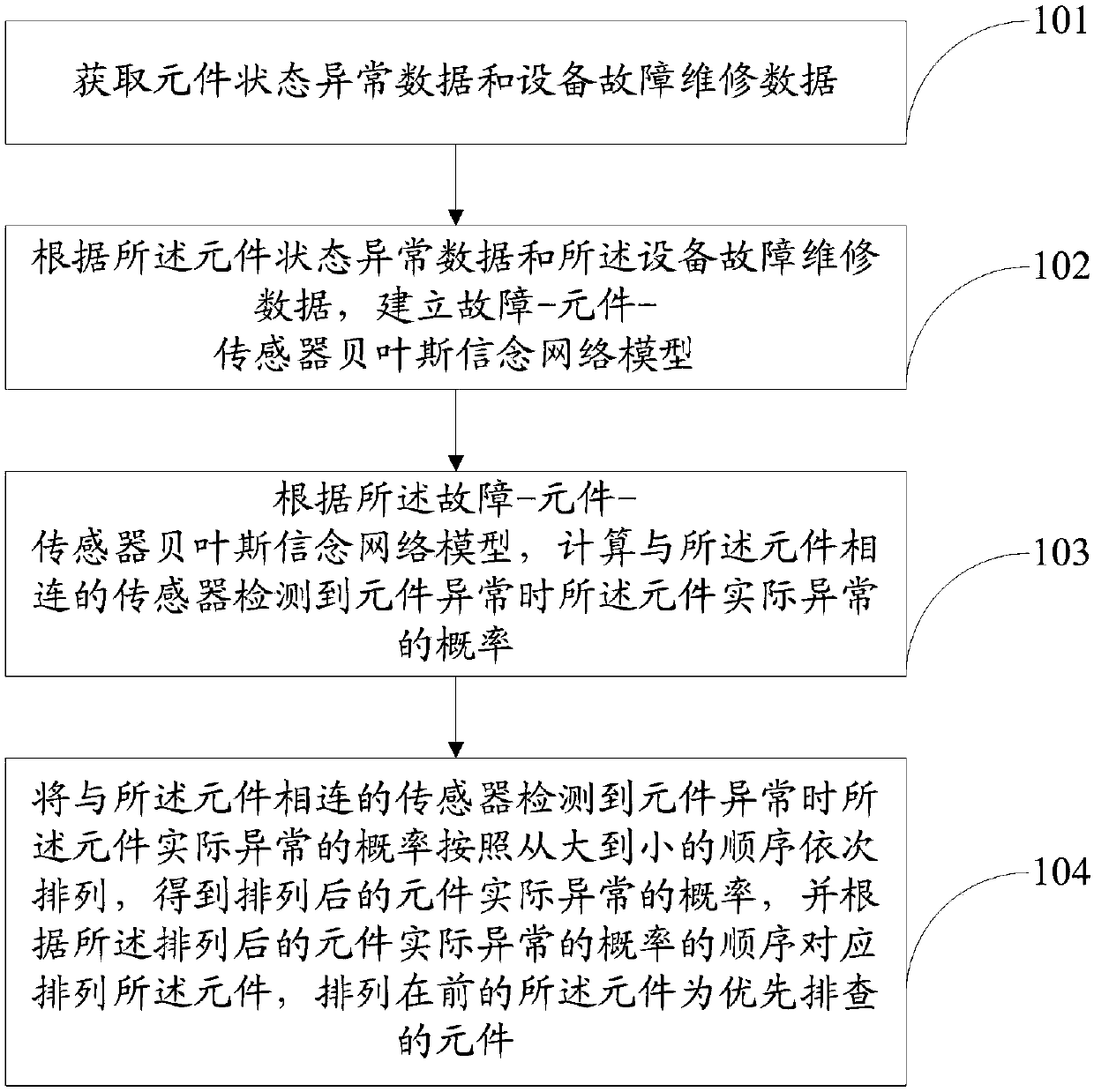

[0066] figure 1 It is a schematic flow chart of the method for troubleshooting equipment fault components in the embodiment of the present invention Figure 1 ,Such as figure 1 As shown, the equipment fault component troubleshooting method provided by the present invention specifically includes the following steps:

[0067] Step 101: Obtain abnormal component status data and equipment failure maintenance data.

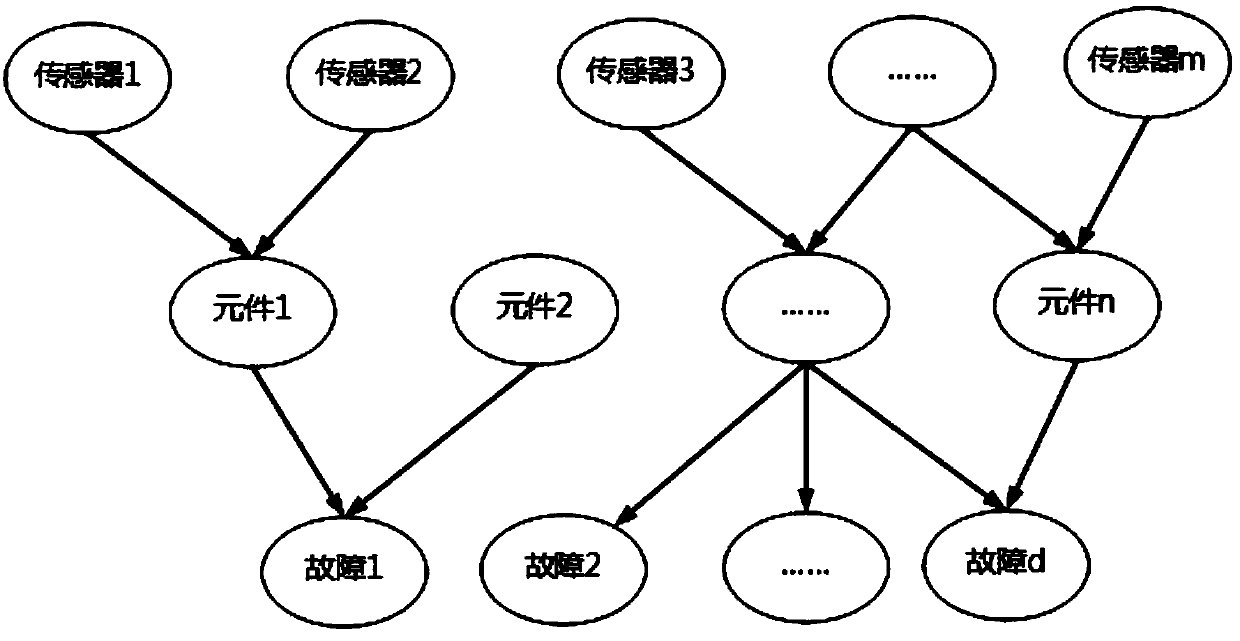

[0068] Step 102: Establish a fault-component-sensor Bayesian belief network model according to the component status abnormal data and the equipment fault maintenance data; the fault-component-sensor Bayesian belief network model includes: sensors, components and Equipment setting failure; in the failure-component-sensor Bayesian belief network model, the sensor is connected to the component, and the component is connected to the equipment setting failure; the sensor is connected to the component Indicates that the sensor detects whether the component is abnormal; th...

Embodiment 2

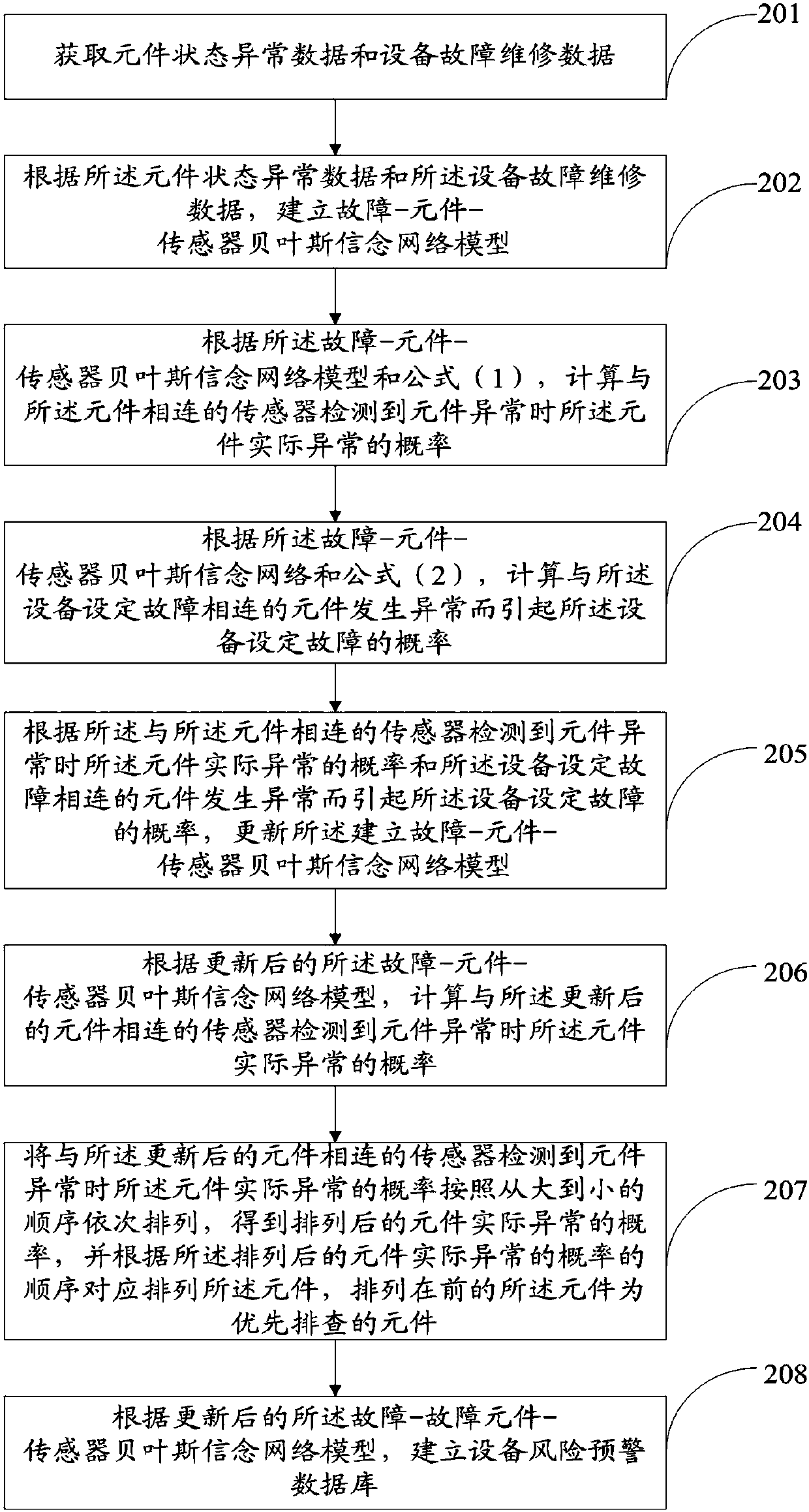

[0080] figure 2 It is a schematic flow chart of the method for troubleshooting equipment fault components in the embodiment of the present invention Figure II ,Such as figure 2 As shown, the equipment fault component troubleshooting method provided by the present invention specifically includes the following steps:

[0081] Step 201: Obtain component state abnormality data and equipment failure maintenance data.

[0082]Step 202: Establish a fault-component-sensor Bayesian belief network model according to the component state abnormal data and the equipment fault maintenance data; the fault-component-sensor Bayesian belief network model includes: sensors, components and Equipment setting failure; in the failure-component-sensor Bayesian belief network model, the sensor is connected to the component, and the component is connected to the equipment setting failure; the sensor is connected to the component Indicates that the sensor detects whether the component is abnormal;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com