Frozen Meat Skewer Production and Cleaning Equipment

A technology for cleaning equipment and meat skewers, applied in the field of meat making machines, can solve the problems of being difficult to clean, sticking to the side wall of the knife, and different sizes of meat pieces, so as to improve efficiency and quality, improve cutting quality, and reduce labor effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

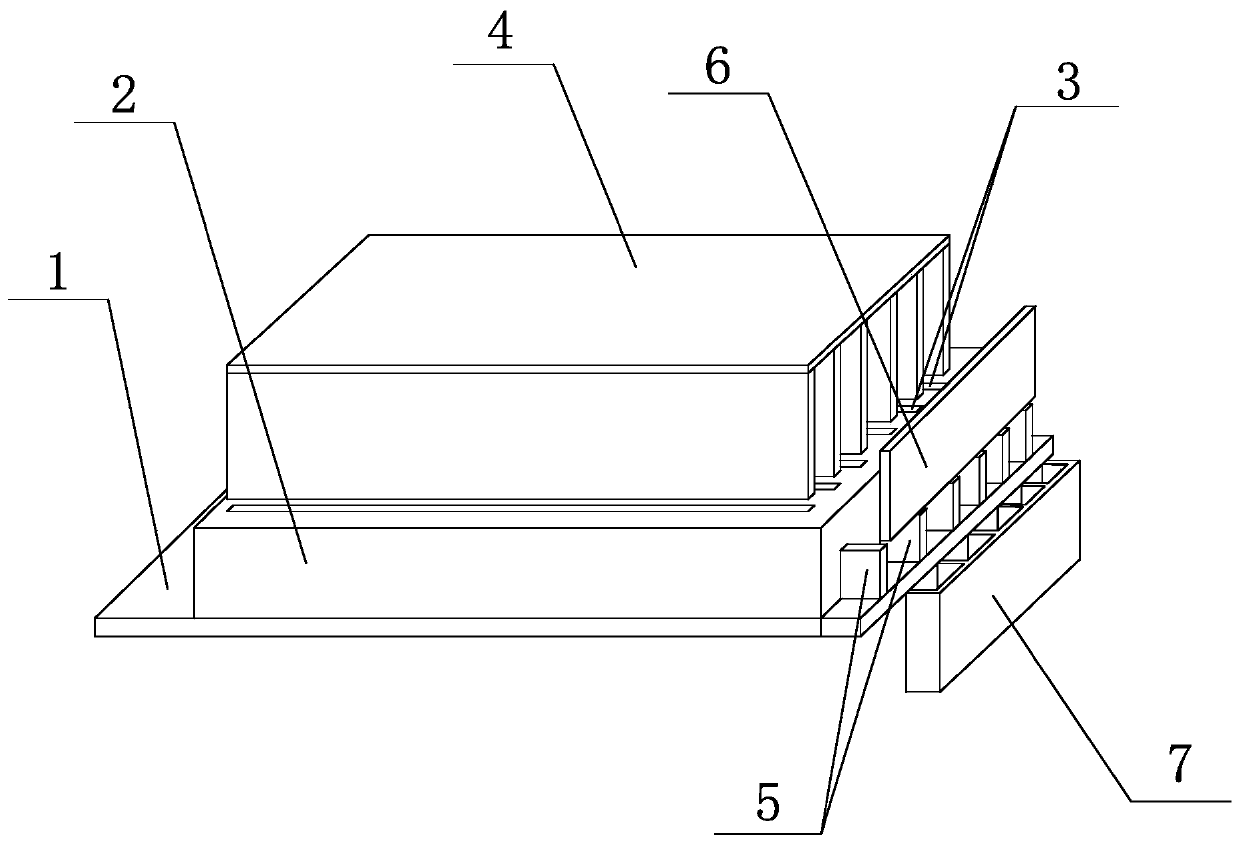

[0023] Such as figure 1 As shown, a kind of skewer production and cleaning equipment of frozen meat of the present invention comprises workbench 1, and described workbench 1 is provided with meat cutting box 2, and the two end faces of meat cutting box 2 are open, and meat cutting box 2 and working Table 1 forms a channel with openings at both ends, and the top surface of meat cutting box 2 is provided with a plurality of knife-entry openings 3 arranged in parallel, and the knife-entry openings 3 are arranged in parallel with the passage; Group 4 comprises a plurality of cutters whose thickness matches the width of the knife edge 3; an open end of the channel is vertically provided with a plurality of parallel meat partitions 5, and the distance between adjacent meat partitions 5 is the same as that between the knife inlet 3. The spacing is the same, and the meat partition 5 is provided with a cutting tool 6 at an end face far away from the meat cutting box 2, and the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com