Intelligent centrifuge monitoring system

A monitoring system and centrifuge technology, applied in the field of centrifuges, can solve problems such as construction period affecting production, waste of time, and inability to understand equipment operation in real time, so as to avoid failures, improve stability and safety, and save inspection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

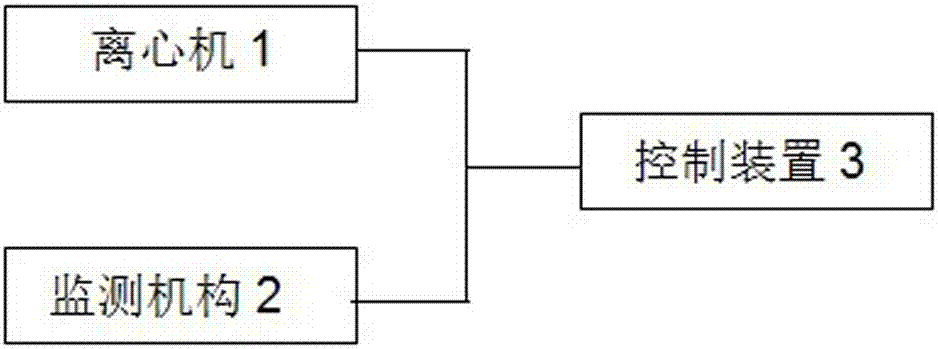

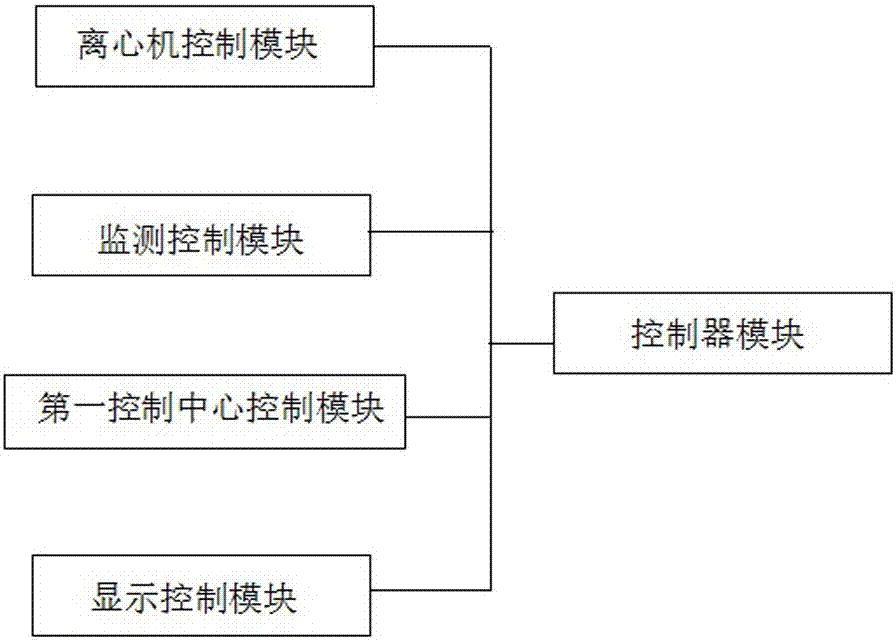

[0020] Such as figure 1 and figure 2 The shown intelligent centrifuge monitoring system includes: a centrifuge 1, a monitoring mechanism 2 and a control device 3, and the monitoring mechanism 2 is provided with a detection module and a conversion module;

[0021] The relationship between the above components is as follows:

[0022] The detection module is provided with a vibration sensor, a pressure sensor, a speed proximity switch and a temperature sensor, the detection module is connected to the conversion module, the vibration sensor is used to detect the vibration frequency of the centrifuge, and the speed proximity switch is used to control the centrifuge. The rotating speed of the machine 1; the input and output ends of the monitoring mechanism 2 are respectively connected with the centrifuge 1 and the control device 3, and the first control center and the second control center are arranged in the control device 3, and the first control center There are transmitters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com