Flow and pressure divided cavity coordinated control load simulation method

A technology of coordinated control and load simulation, which is applied in the field of simulation, can solve problems such as failure to meet high dynamic load simulation requirements, low energy utilization efficiency, and large excess force interference, etc., to achieve good excess force suppression effect, flexible optional types, and elimination of The effect of forced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

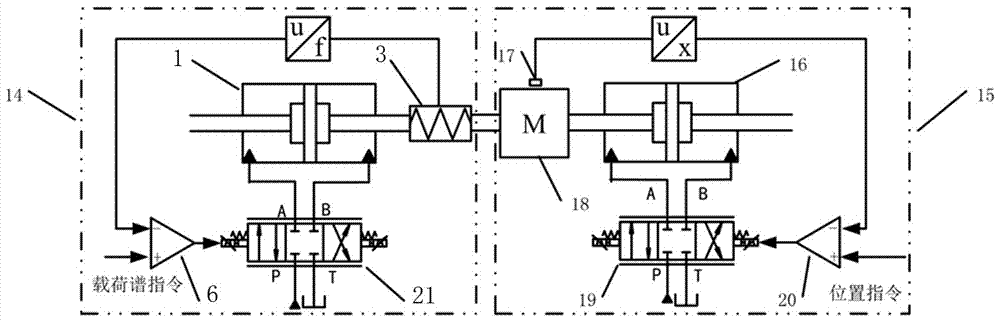

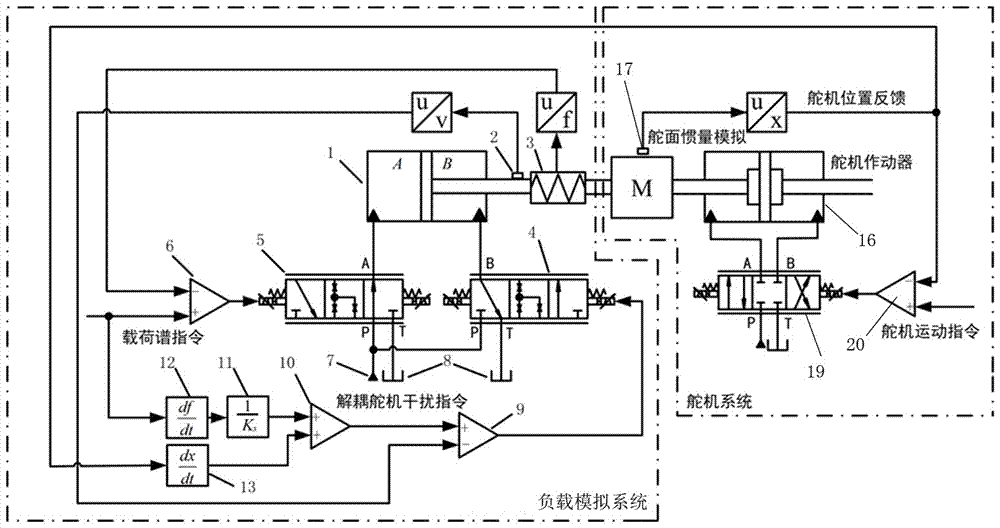

Method used

Image

Examples

Embodiment

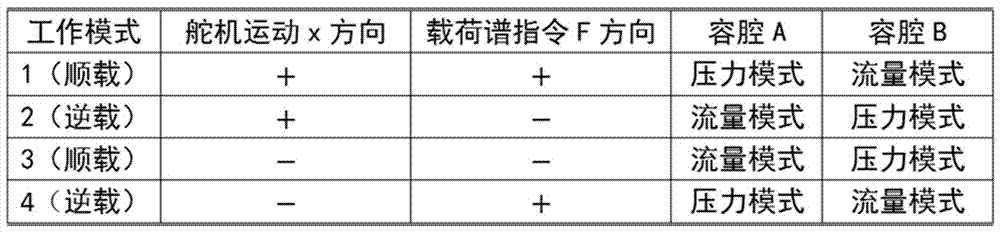

[0028] According to the direction of movement of the steering gear system and the size of the load spectrum command, the working modes of the negative loading device can be divided into four types. In order to facilitate the analysis, first define the movement direction X of the steering gear and the sign of the load spectrum command F as follows: It is stipulated that when the direction of X and F is consistent with the positive direction of the horizontal axis of the Cartesian coordinate system, it is positive, and when it is opposite, it is negative.

[0029] Such as figure 2As shown, when the direction of movement of the steering gear and the command direction of the load spectrum are both positive (working mode 1), the chamber A of the loading actuator works in the pressure mode, and the chamber B works in the flow mode; when the movement direction of the steering gear is positive, When the load spectrum command is negative (working mode 2), the loading actuator chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com