Construction method for reinforced carbon fiber cloth composite layer and pipeline crack arrester applying same

A carbon fiber cloth and construction method technology, applied in the field of oil and gas transmission pipeline fracture control, can solve the problems of high time-consuming and economical cost, inability to mass-produce, secondary damage to pipelines, etc., achieving low construction environment requirements, easy on-site installation, The effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

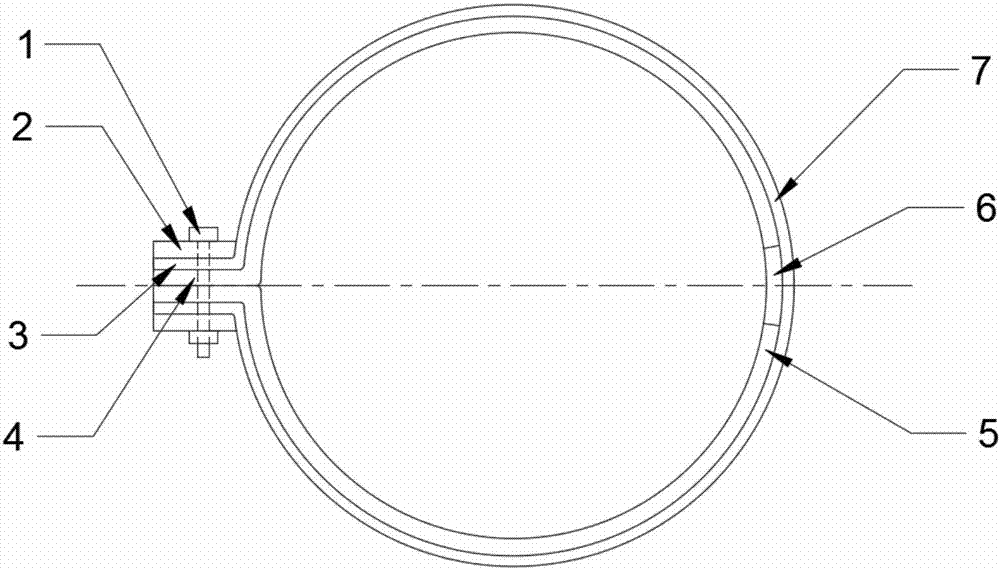

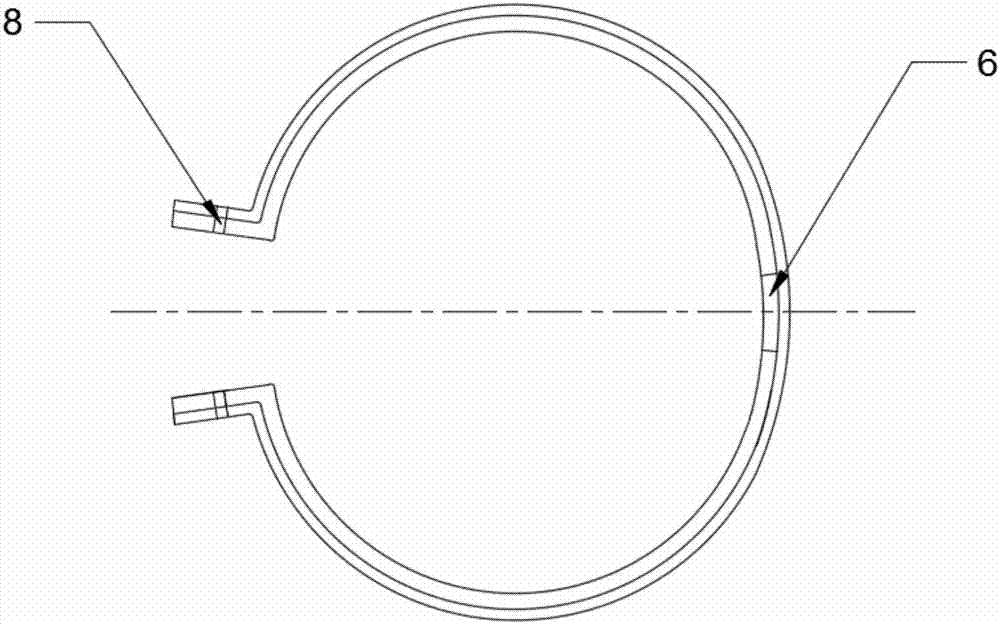

[0035] The present invention will be further described below in conjunction with accompanying drawing:

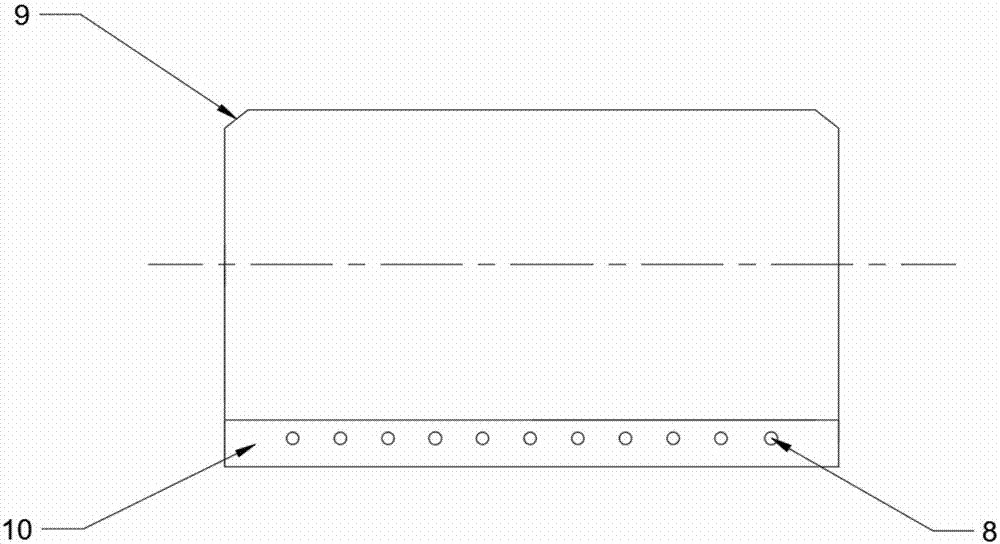

[0036] First, the construction method of the reinforced carbon fiber cloth composite layer for making this kind of crack stopper is given. The method is: at least four layers of reinforced carbon fiber cloth with the same shape are stacked, and the reinforced carbon fiber is cured after being impregnated with a binder. Cloth composite layer; the tensile directions of each layer of reinforced carbon fiber cloth alternately have included angles in the order from top to bottom, and the range of the included angle is 15 o ~60 oBetween; the reinforced carbon fiber cloth at each angle is formed by stacking at least two reinforced carbon fiber cloths with the same main fiber direction. In addition, in order to realize the activities of the reinforced carbon fiber cloth composite layer, it is necessary to leave a non-cured belt without binder impregnation in the middle section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com