Trajectory Planning Method for Grinding Workpieces Supported by Robots Based on Offline Programming

An offline programming and trajectory planning technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., to reduce the difficulty of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

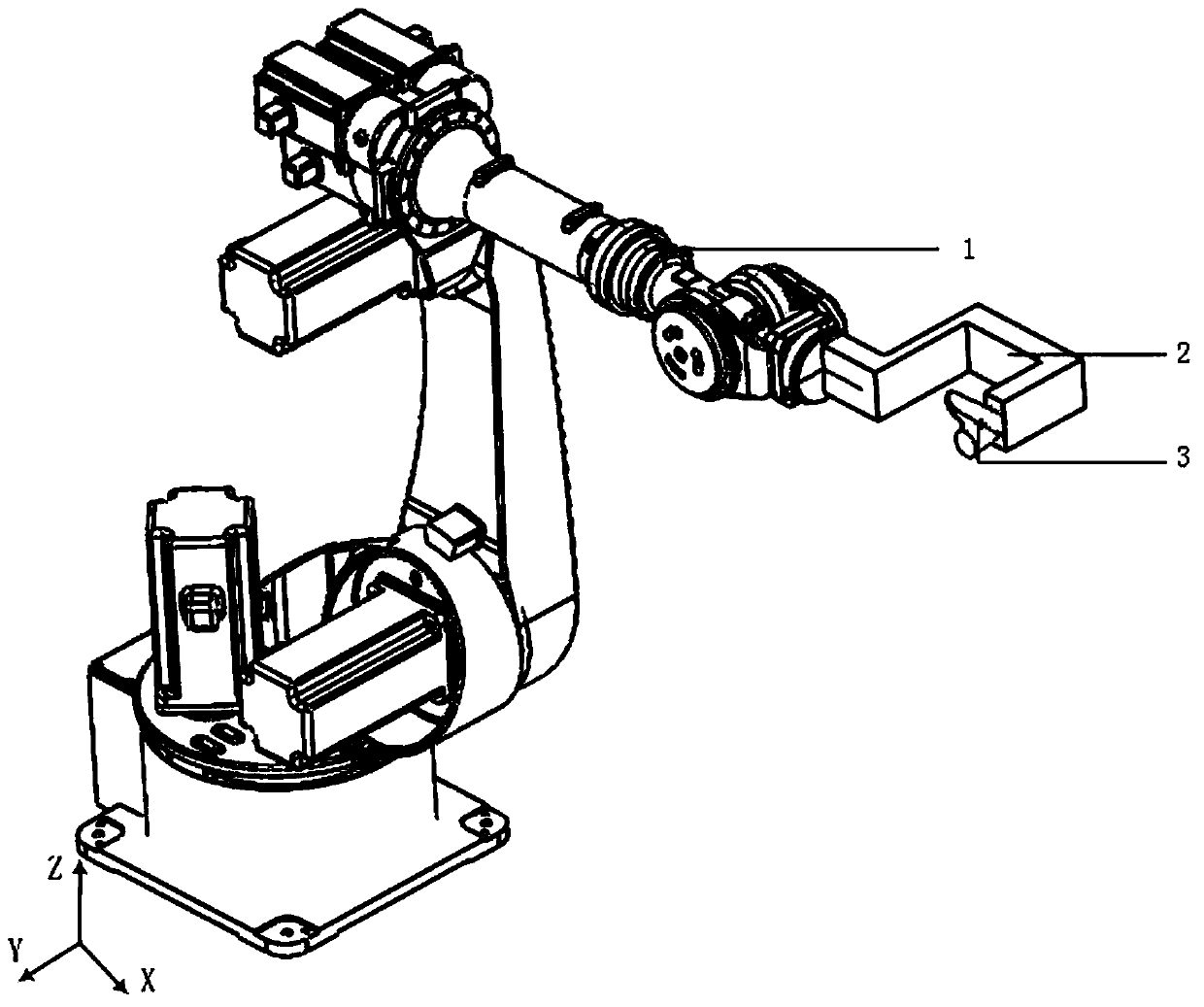

[0044] Example: In the present invention, a six-joint tandem robot blessed with faucet polishing is taken as an example to illustrate the steps of the method of the present invention:

[0045] 1. Import the assembly model of the faucet of the six-joint tandem robot into the 3D modeling software, make the robot base zero point at the origin of the assembly coordinate system, and make the X axis positive direction of the robot coordinate system point to the positive X axis direction of the assembly coordinate system , The positive direction of the Y axis of the robot coordinate system points to the positive direction of the Y axis of the assembly coordinate system, and the positive direction of the Z axis of the robot coordinate system points to the positive direction of the Z axis of the assembly coordinate system, so that the robot coordinate system and the assembly coordinate system are The origin and direction are exactly the same;

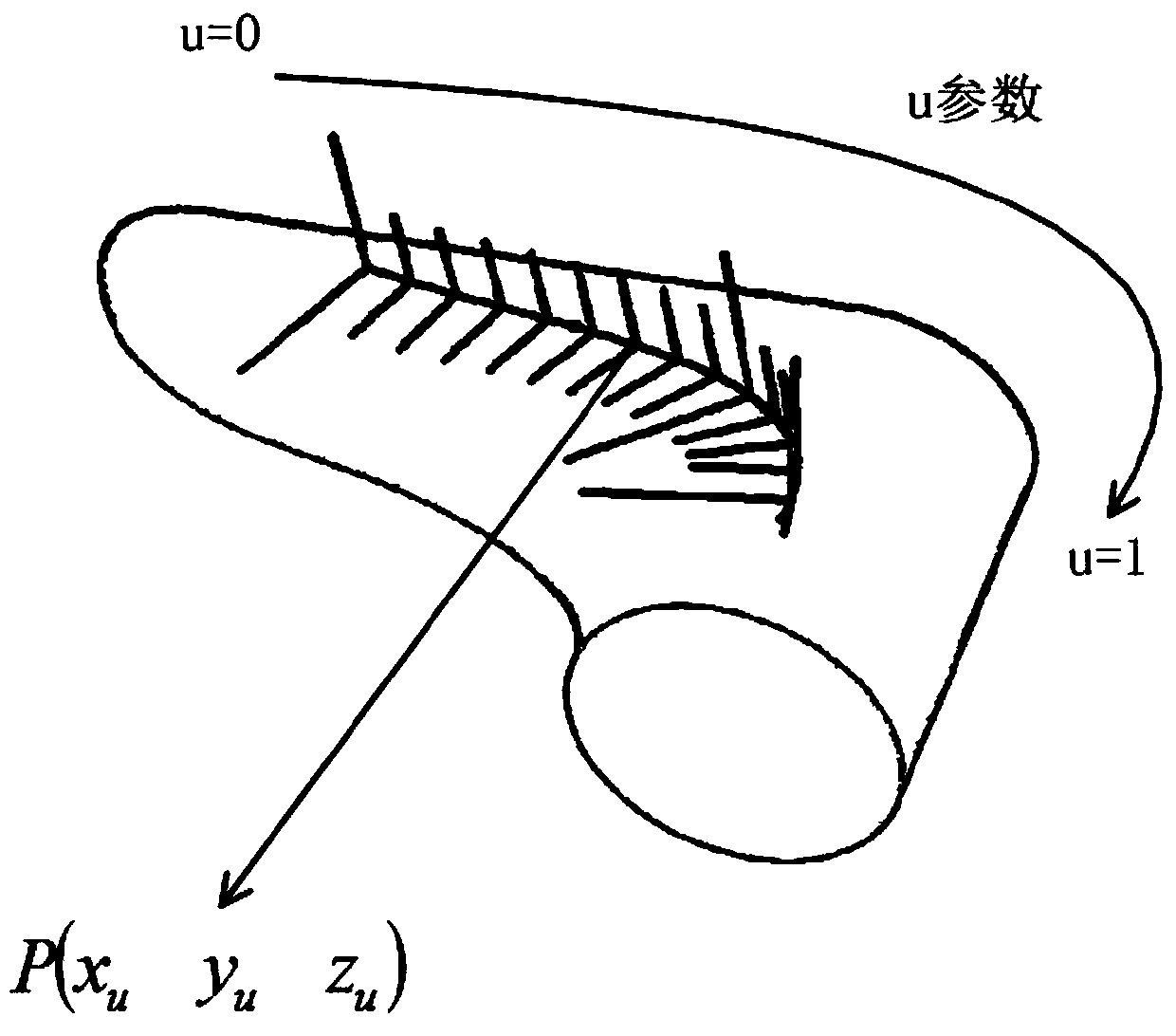

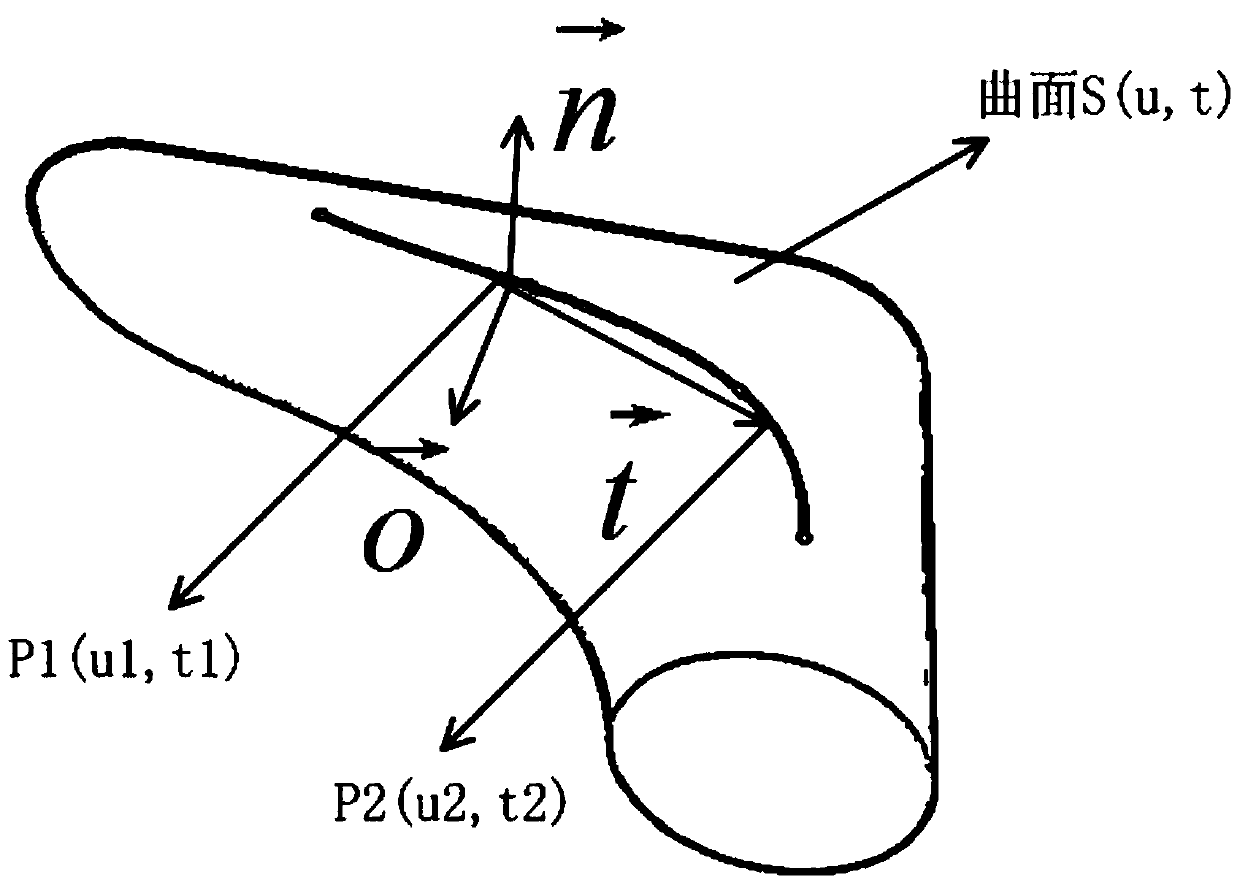

[0046] 2. In this example, use the robot's def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com