Preparation method of mellow modified corn flour and application

A corn flour and modified technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems of changing the processing quality and nutritional quality of corn flour, rough taste of corn flour, poor plasticity of corn flour dough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

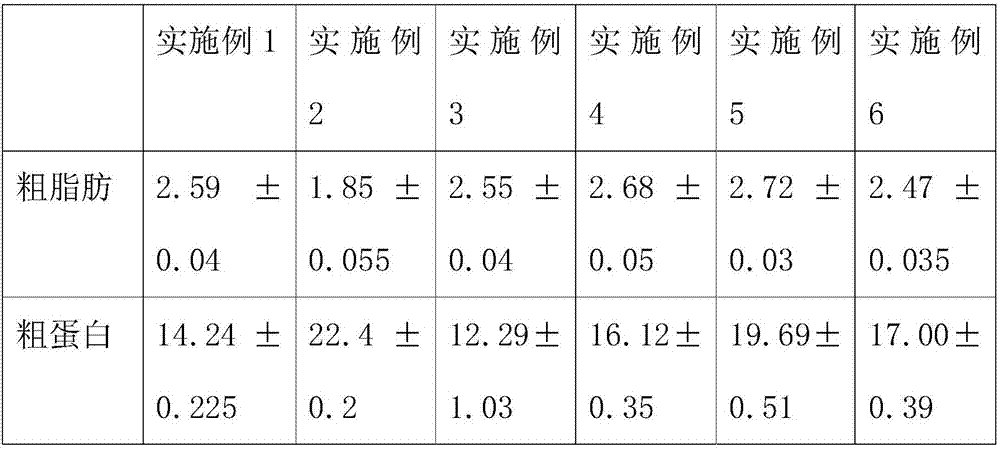

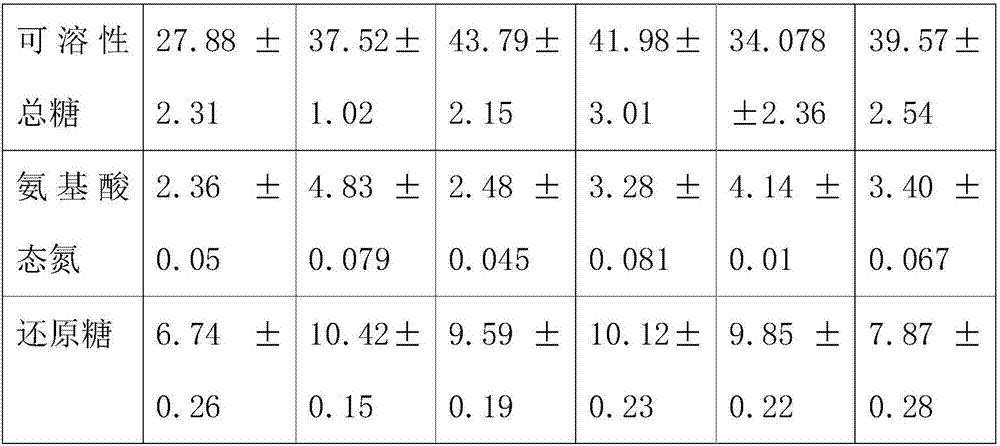

Examples

Embodiment 1

[0026] A preparation method of modified corn flour, comprising the following steps:

[0027] a. Strain preparation steps:

[0028] a1: Preparation of slant strains: Flammulina velutipes and Saccharomyces cerevisiae are inoculated on the slant medium for cultivation, the slant medium is PDA medium, and the culture conditions are: 25-28°C, with In activated bacteria;

[0029] a2: Preparation of liquid spawn:

[0030] Flammulina velutipes liquid strain: add 200mL liquid culture medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid culture medium, shake and culture at 25°C and 130r / min for 5 days, and then it is ready;

[0031] Described liquid culture medium comprises following material: Glucose 3%, peptone 0.2%, MgSO 4 ·7H 2 O 0.05%, CaCl 2 0.01%, KH 2 PO 4 0.05%, the rest is water;

[0032] Saccharomyces cerevisiae liquid strain: Add 200mL liquid medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid medium, sha...

Embodiment 2

[0038] A preparation method of modified corn flour, comprising the following steps:

[0039] a1: Preparation of slant strains: Flammulina velutipes and Saccharomyces cerevisiae are inoculated on the slant medium for cultivation, the slant medium is PDA medium, and the culture conditions are: 25-28°C, with In activated bacteria;

[0040] a2: Preparation of liquid spawn:

[0041] Flammulina velutipes liquid strain: add 200mL liquid culture medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid culture medium, shake and culture at 25°C and 130r / min for 5 days, and then it is ready;

[0042] Described liquid culture medium comprises following material: Glucose 3%, peptone 0.2%, MgSO 4 ·7H 2 O 0.05%, CaCl 2 0.01%, KH 2 PO 4 0.05%, the rest is water;

[0043] Saccharomyces cerevisiae liquid strain: Add 200mL liquid medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid medium, shake and culture at 25°C and 130r / min for...

Embodiment 3

[0049] A preparation method of modified corn flour, comprising the following steps:

[0050] a1: Preparation of slant strains: Flammulina velutipes and Saccharomyces cerevisiae are inoculated on the slant medium for cultivation, the slant medium is PDA medium, and the culture conditions are: 25-28°C, with In activated bacteria;

[0051] a2: Preparation of liquid spawn:

[0052] Flammulina velutipes liquid strain: add 200mL liquid culture medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid culture medium, shake and culture at 25°C and 130r / min for 5 days, and then it is ready;

[0053] Described liquid culture medium comprises following material: Glucose 3%, peptone 0.2%, MgSO 4 ·7H 2O 0.05%, CaCl 2 0.01%, KH 2 PO 4 0.05%, the rest is water;

[0054] Saccharomyces cerevisiae liquid strain: Add 200mL liquid medium to the Erlenmeyer flask (500mL), inoculate the slant strain into the liquid medium, shake and culture at 25°C and 130r / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com