Secondary pressure relief valve

A secondary decompression and decompression valve technology, which is applied in the field of decompression valves, can solve problems such as high cost, unstable decompression, and large volume, and achieve the effect of solving weld bead bubbles and top gun blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

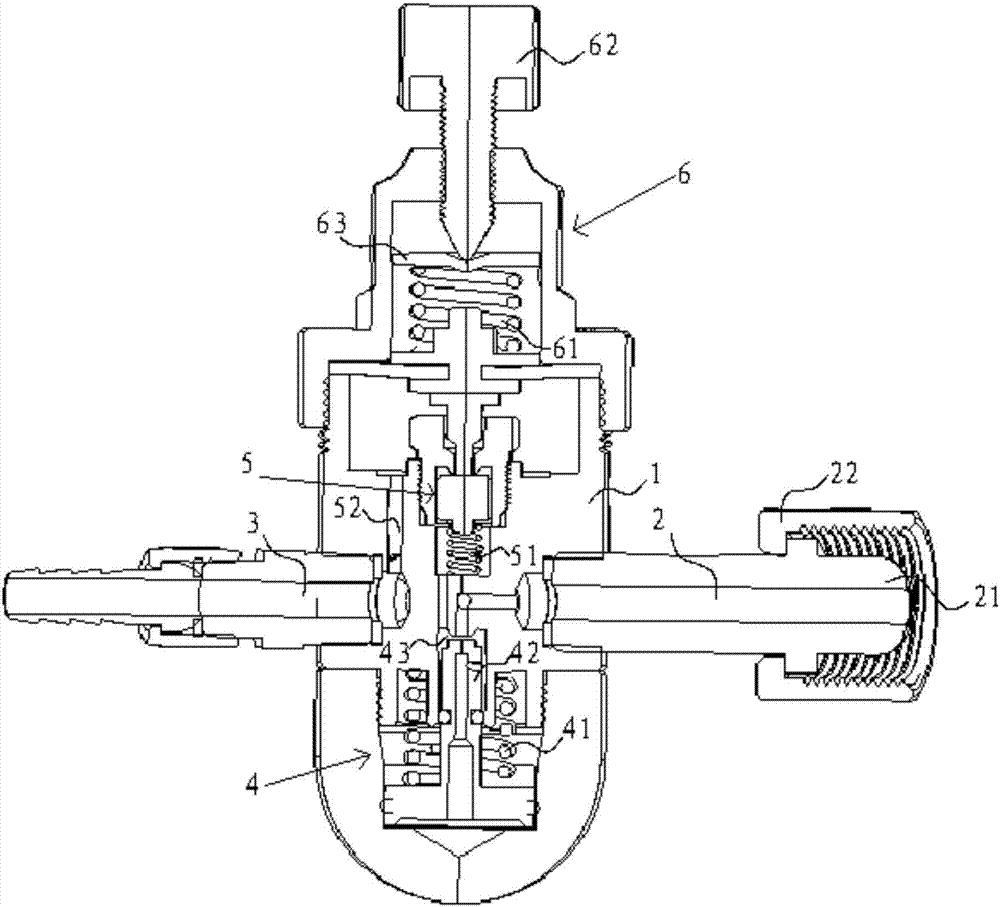

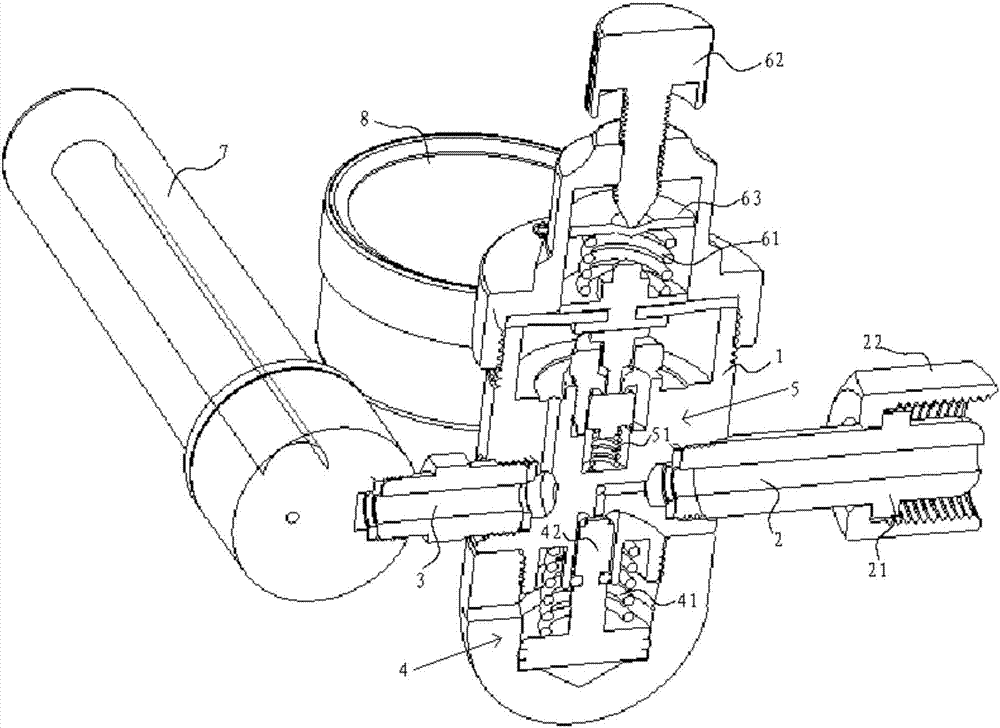

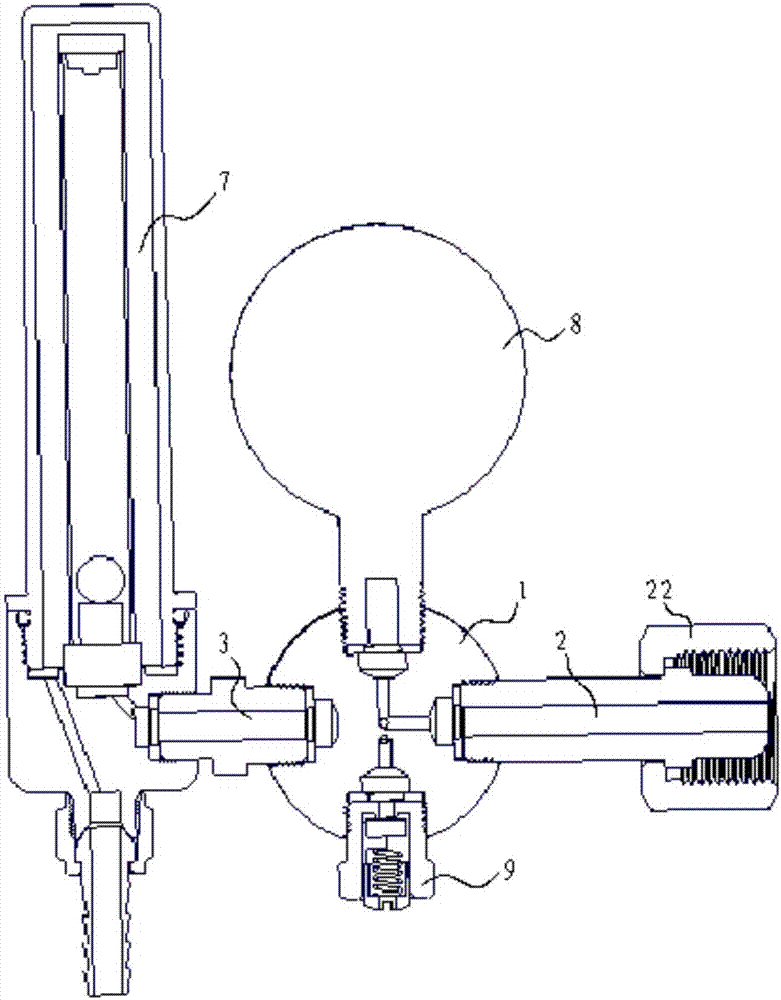

[0018] Such as figure 1 , 2 As shown, the secondary decompression valve includes a valve body 1, the valve body 1 is provided with an air inlet 2 and an air outlet 3, and the valve body 1 is provided with a primary decompression valve assembly 4 and a secondary decompression valve assembly 5 , the primary decompression valve assembly 4 includes a primary spring 41, a piston 42 and a primary vent hole 43, the piston 42 is installed in cooperation with the primary spring 41, and the primary vent hole 43 is connected to the air inlet 2 and the secondary decompression valve assembly 5 , the secondary decompression valve assembly 5 includes a secondary spring 51 and a secondary vent hole 52 , and the secondary vent hole 52 is connected to the air outlet 3 .

[0019] The valve body 1 is provided with an adjustment device 6 , and the adjustment device 6 includes an adjustment spring 61 , and the adjustment spring 61 cooperates with the secondary decompression valve assembly 5 . The...

Embodiment 2

[0029] For the secondary pressure reducing valve, on the basis of Embodiment 1, the low-pressure flow assembly 7 adopts a low-pressure gauge, and the pressure of the air outlet 3 is displayed through the detection of the low-pressure gauge, which is intuitive and simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com