Bismuth-doped phosphosilicate glass and preparation method thereof

A technology of phosphosilicate glass and phosphate glass, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of enhancing luminescence bandwidth, reducing bismuth luminescence performance, difficult to prepare high proportion, etc., and achieving high fluorescence half width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

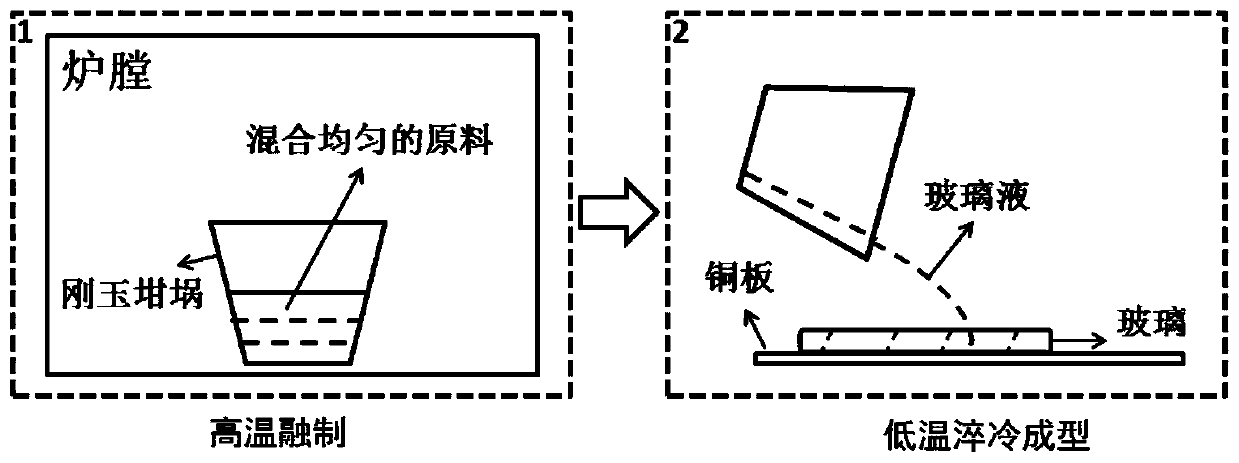

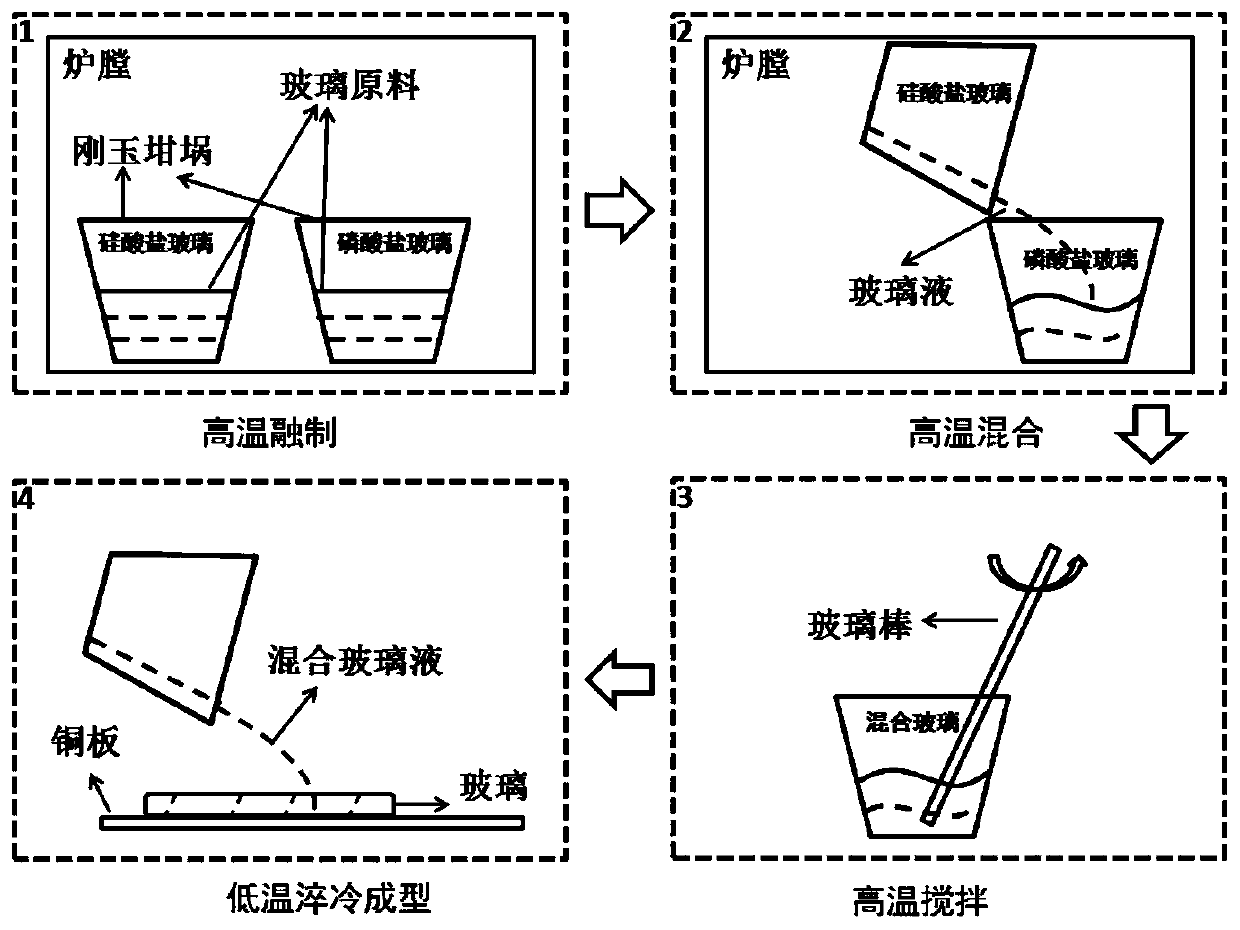

Method used

Image

Examples

Embodiment 1

[0029] Example 1: 50 (65SiO 2 -9Al 2 o 3 -25CaO-1Bi 2 o 3 )-50(82P 2 o 5 -17Al 2 o 3 -1Bi 2 o 3 )

[0030] Preparation method: According to the above molar ratio, weigh 16g and 34g of silicate and phosphate matrix glass raw materials respectively, totaling 50g, of which P 2 o 5 The ratio is 41mol.%, put into a ball mill and stir for 1 hour, then put into two crucibles, and preheat in a furnace at 600°C for 60min. Transfer the preheated raw materials to a furnace at 1600°C, and cover the crucible containing the phosphate glass raw materials. Melt for 120 minutes, then pour the silicate glass stock solution into the phosphate stock solution in the furnace, or pour the phosphate stock solution into the silicate glass stock solution, stir for 10 seconds, and pour it on a copper plate preheated at 500°C. Pressed into thin slices of 3mm thickness. Put it into a furnace at 500°C for annealing for 180 minutes, and cool down to room temperature with the furnace cooling. ...

example 2

[0031] Example 2: 40 (65SiO 2 -10Al 2 o 3 -25CaO-1Bi 2 o 3 )-60(82P 2 o 5 -18Al 2 o 3 -1Bi 2 o 3 )

[0032] Preparation method: According to the above molar ratio, weigh 12g and 38g of silicate and phosphate matrix glass raw materials respectively, totaling 50g, of which P 2 o 5The proportion is 49.2 mol.%. Bismuth-doped phosphosilicate glass is prepared by the same method as in Example 1 to obtain the final product. Carry out performance test to the sample, among them, image 3 The second from the left is the actual picture of the prepared glass; Figure 4 is the fluorescence spectrum of the sample excited by a near-infrared semiconductor laser, and its fluorescence half maximum width is 255nm.

example 3

[0033] Example 3: 30 (65SiO 2 -10Al 2 o 3 -25CaO-1Bi 2 o 3 )-70(82P 2 o 5 -18Al 2 o 3 -1Bi 2 o 3 )

[0034] Preparation method: According to the above molar ratio, weigh 8g and 42g of silicate and phosphate matrix glass raw materials respectively, totaling 50g, of which P 2 o 5 The ratio is 57.4 mol.%. Bismuth-doped phosphosilicate glass is prepared by the same method as in Example 1 to obtain the final product. Carry out performance test to the sample, among them, image 3 The third from the left is the actual picture of the prepared glass; Figure 4 is the fluorescence spectrum of the sample excited by a near-infrared semiconductor laser, and its fluorescence half-maximum width is 265nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com