Ore collecting and crushing device for mining industry

A technology of crushing device and ore, applied in the direction of using liquid separating agent, grain processing, dispersing particle separation, etc., can solve the problems of high labor intensity, easy occurrence of dust, affecting the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

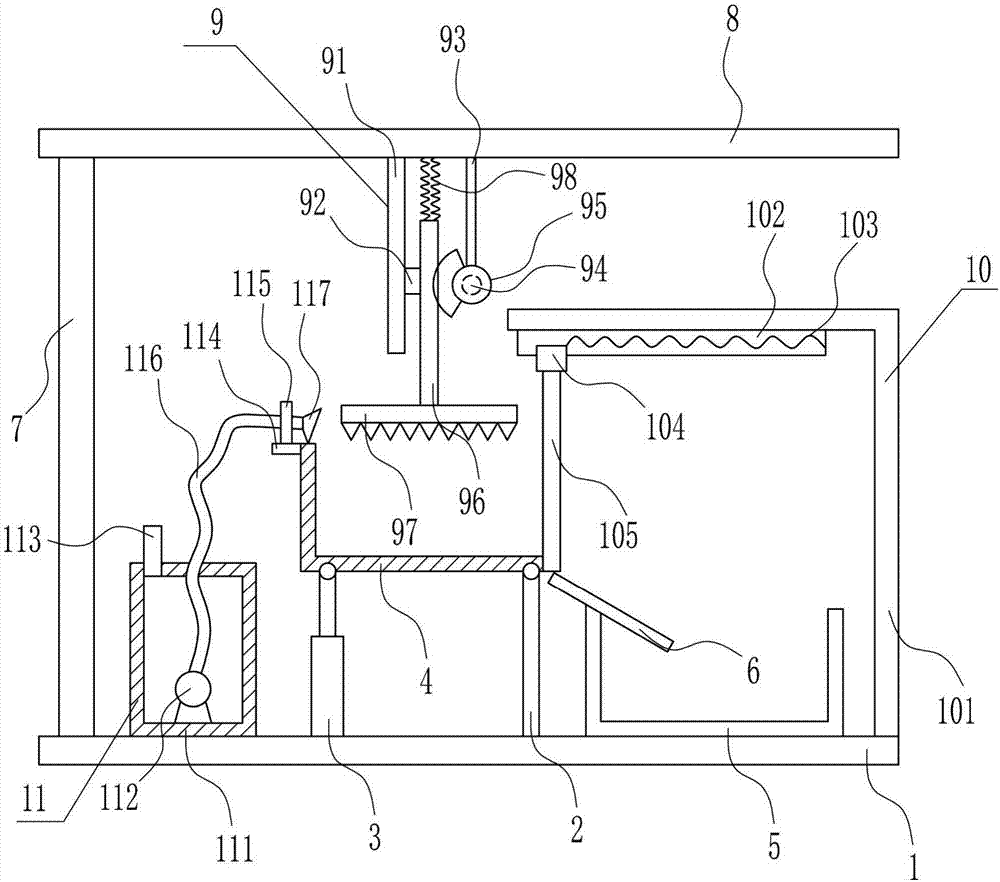

[0027] A kind of ore collecting crushing device for mining, such as Figure 1-3As shown, it includes a bottom plate 1, a support rod 2, a cylinder 3, a crushing frame 4, a collection frame 5, an inclined plate 6, a support plate 7, a top plate 8, a crushing device 9 and a material retaining device 10, and the bottom right side of the bottom plate 1 is passed through a bolt The connection method is to install a support rod 2, the top of the support rod 2 is connected with a crushing frame 4, and the left side of the bottom plate 1 is connected with a bolt to install a cylinder 3, the cylinder 3 is vertically arranged, and the expansion and contraction of the cylinder 3 The rod is connected to the left side of the outer bottom of the crushing frame 4 through a pin connection, and the collection frame 5 is installed on the top right side of the bottom plate 1 through bolt connection. The way of connection is installed with a sloping plate 6, the sloping plate 6 is located at the ...

Embodiment 2

[0029] A kind of ore collecting crushing device for mining, such as Figure 1-3 As shown, it includes a bottom plate 1, a support rod 2, a cylinder 3, a crushing frame 4, a collection frame 5, an inclined plate 6, a support plate 7, a top plate 8, a crushing device 9 and a material retaining device 10, and the bottom right side of the bottom plate 1 is passed through a bolt The connection method is to install a support rod 2, the top of the support rod 2 is connected with a crushing frame 4, and the left side of the bottom plate 1 is connected with a bolt to install a cylinder 3, the cylinder 3 is vertically arranged, and the expansion and contraction of the cylinder 3 The rod is connected to the left side of the outer bottom of the crushing frame 4 through a pin connection, and the collection frame 5 is installed on the top right side of the bottom plate 1 through bolt connection. The way of connection is installed with a sloping plate 6, the sloping plate 6 is located at the...

Embodiment 3

[0032] A kind of ore collecting crushing device for mining, such as Figure 1-3 As shown, it includes a bottom plate 1, a support rod 2, a cylinder 3, a crushing frame 4, a collection frame 5, an inclined plate 6, a support plate 7, a top plate 8, a crushing device 9 and a material retaining device 10, and the bottom right side of the bottom plate 1 is passed through a bolt The connection method is to install a support rod 2, the top of the support rod 2 is connected with a crushing frame 4, and the left side of the bottom plate 1 is connected with a bolt to install a cylinder 3, the cylinder 3 is vertically arranged, and the expansion and contraction of the cylinder 3 The rod is connected to the left side of the outer bottom of the crushing frame 4 through a pin connection, and the collection frame 5 is installed on the top right side of the bottom plate 1 through bolt connection. The way of connection is installed with a sloping plate 6, the sloping plate 6 is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com