A joint for a frame fan assembly

An assembly and frame fan technology, which is applied to the joint field of frame fan assemblies, can solve the problems of looseness, impact on life, installation deviation, etc., and achieve the effect of improving service life, improving installation efficiency, and preventing scratches and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

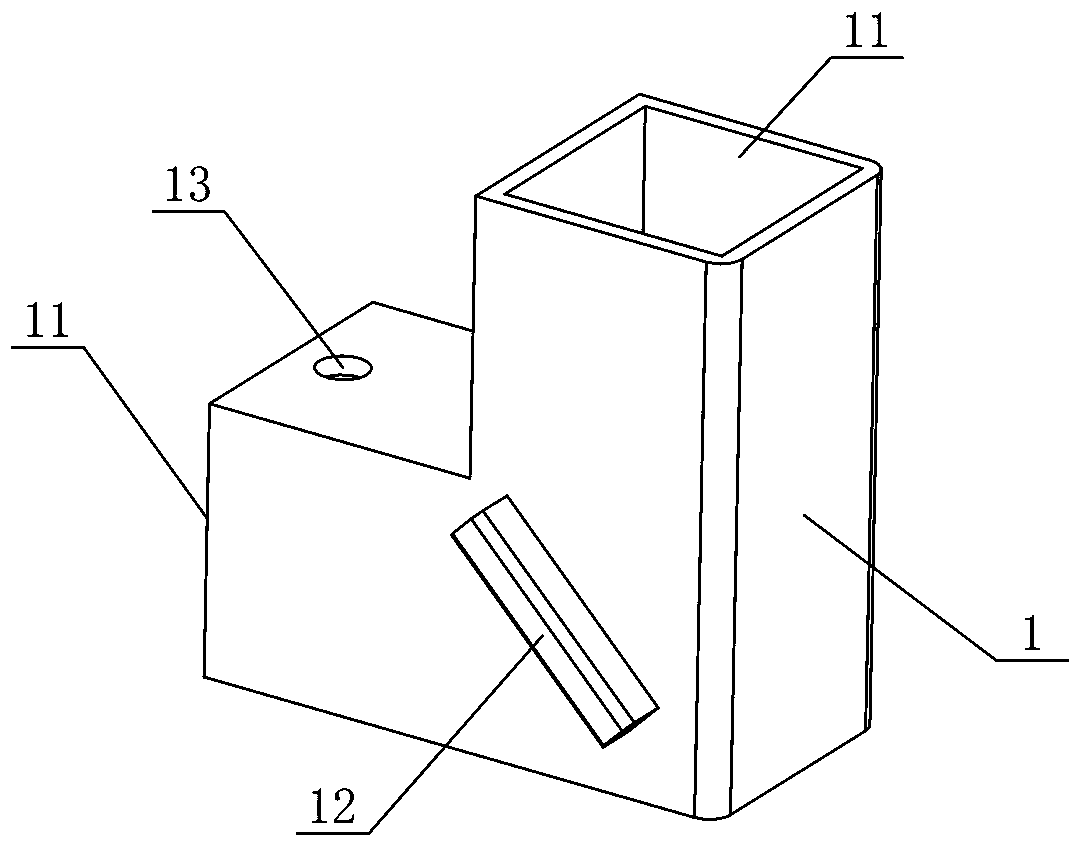

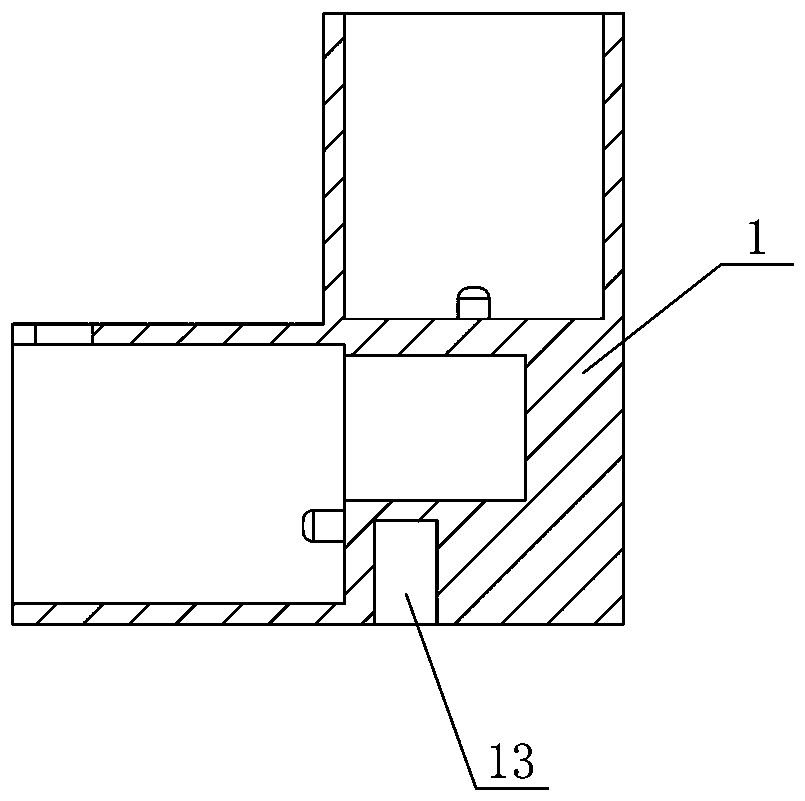

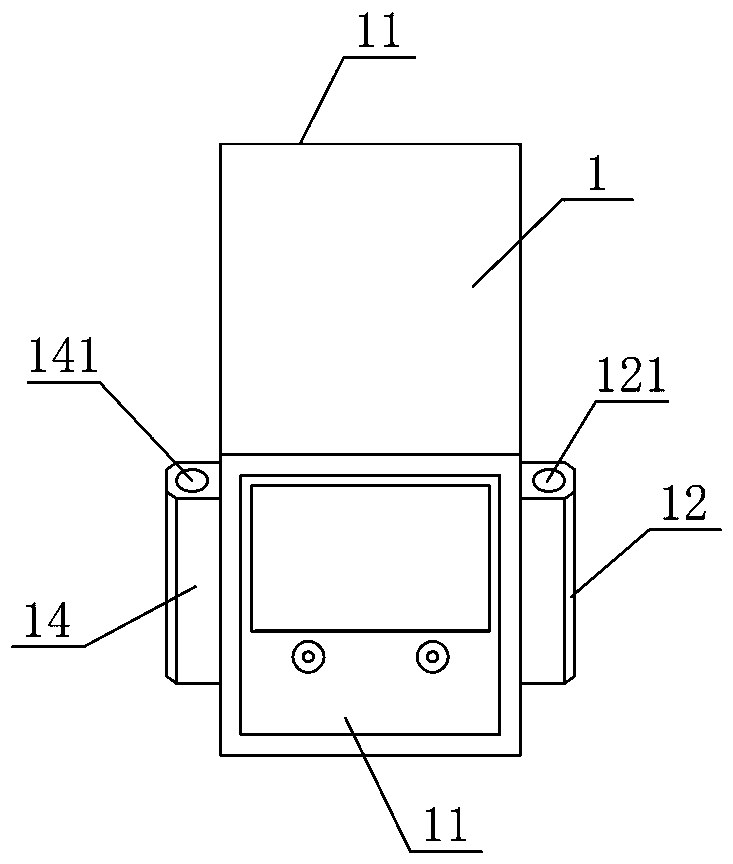

[0068] Figure 1 to Figure 7 It shows the first embodiment of the joint used in the frame sash assembly of the present invention, the joint used in the frame sash assembly includes a joint body 1, and the joint body 1 is provided with at least two connections for connecting frame sash rods part 11, the joint body 1 is also provided with a pull-joint part 12, a hinge part 13 and a plug-in part 14, the pull-joint part 12 is equipped with a cable 2, and the plug-in part 14 is equipped with a latch 3. In this structure, the ends of adjacent frame horizontal bars and frame vertical bars are connected and enclosed by the joint body 1 to form a frame structure, and the ends of adjacent fan horizontal bars and fan vertical bars are connected and enclosed by joint bodies 1 to form a fan frame structure. Frame structure, compared with the traditional built-in connecting hinge, the joint body 1 is externally installed at the end of the rod, so that it is convenient to form the pull joint...

Embodiment 2

[0077] Figure 8 to Figure 10 It shows the second embodiment of the joint used in the frame leaf assembly of the present invention, the joint used in the frame leaf assembly is basically the same as the first embodiment, the difference is that: in this embodiment, the hinge part 13 is set to be formed on the joint The boss on the body 1. In this structure, one of the frame body and the upper hinge part 13 of the fan body is a convex post, and the other is a connecting hole. Through the cooperation of the connecting hole and the convex post, the fan body can rotate around the convex post of the frame body, thereby realizing the opening and closing of the fan body. Combined function, its structure is simple and practical. Moreover, both the bosses and the connection holes are concealed, and are basically invisible from the outside, which greatly improves the aesthetics.

Embodiment 3

[0079] Figure 11 and Figure 12 Shows the third embodiment of the joint used in the frame fan assembly of the present invention, the joint used in the frame fan assembly is basically the same as the first embodiment, the difference is that in this embodiment, the hinge part 13 is equipped with a hinge column 4. In this structure, the hinged connection between the frame body and the upper hinged column 4 of the fan body is realized through the additionally provided hinged column 4, so as to realize the opening and closing function of the fan body, and its structure is simple and reliable.

[0080] In this embodiment, the hinge portion 13 is provided with a hinge hole 131 , and the hinge column 4 is installed in the hinge hole 131 . In this structure, the opening and closing function of the fan body is realized by inserting the hinge column 4 into the hinge hole 131 on the frame body and the fan body, and its structure is simple and reliable.

[0081] In this embodiment, at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com