Tamping machine for civil engineering

A tamping machine and civil engineering technology, applied in the field of construction machinery, can solve problems such as undulations, uneven ground tamping, etc., and achieve the effect of stable and reliable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

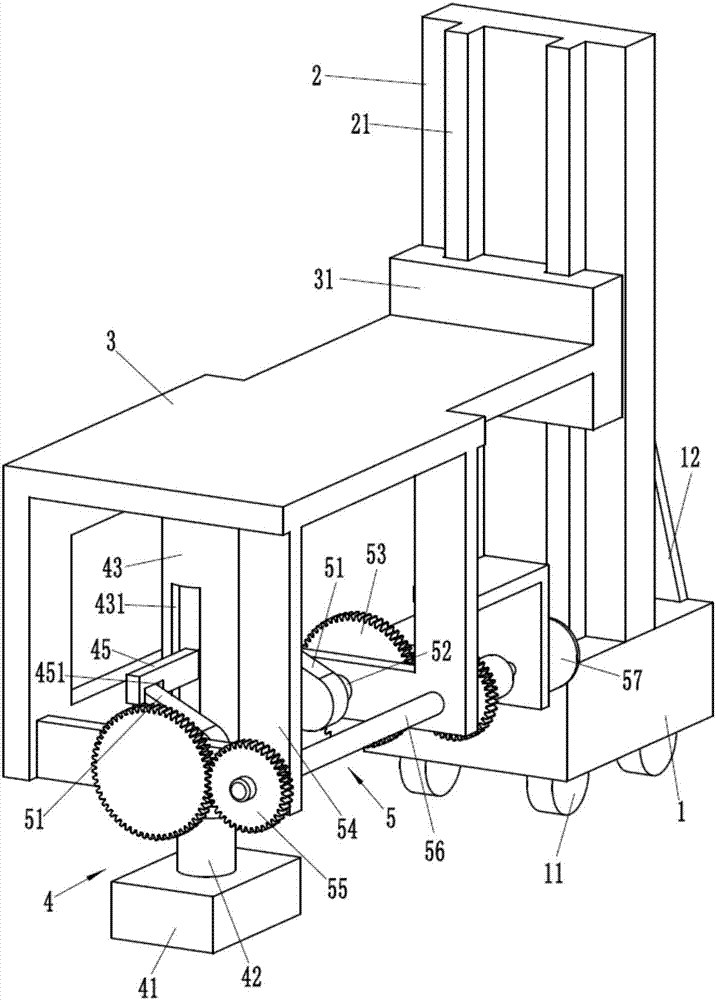

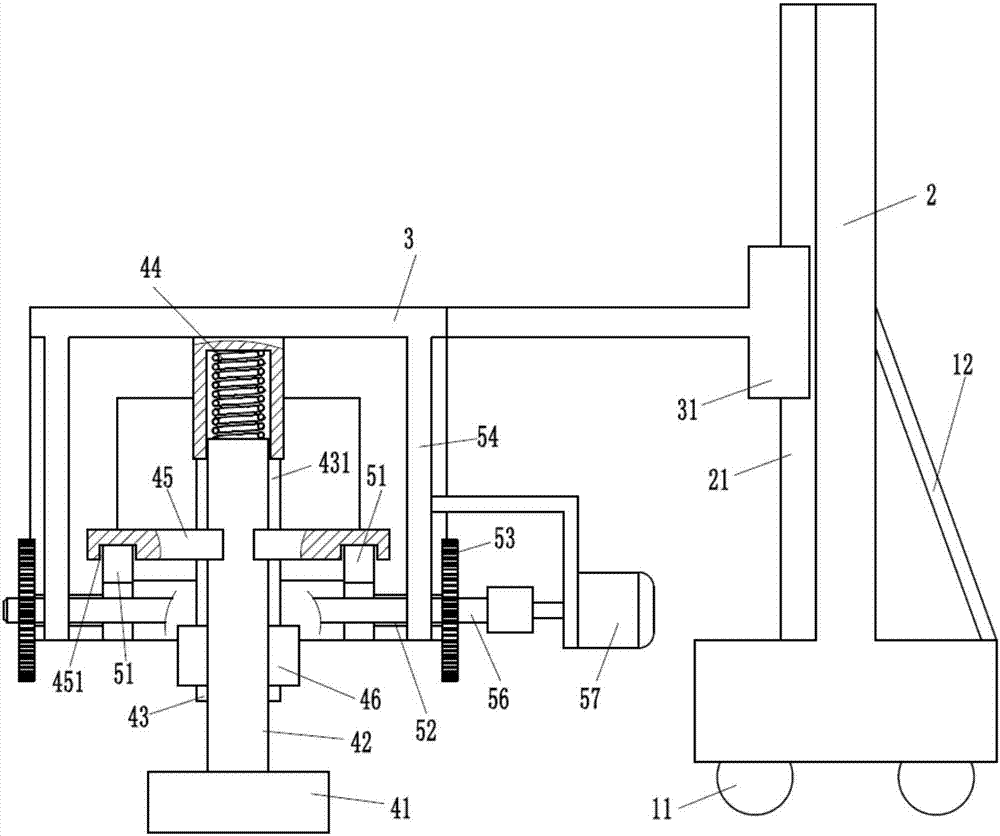

[0019] Examples, see e.g. Figure 1 to Figure 2 As shown, a tamping machine for civil engineering includes a support base 1, a vertical support plate 2 is fixedly connected to the support base 1, and the support plate 2 is slidably connected with a right-angle bearing plate through a vertically arranged slide rail 21. 3. A tamping part 4 is provided on the right-angle bearing plate 3 .

[0020] Furthermore, the tamping part 4 includes a tamp block 41 in the shape of a rectangular bar, the tamp block 41 is fixed on the lower end of the slide bar 42, and the upper end of the slide bar 42 is movably socketed in the cylindrical base 43 , the base 43 is fixed on the right-angle bearing plate 3, the base 43 is sleeved with a compressed spring 44, and the two ends of the spring 44 are respectively pressed against the bottom surface of the inner hole of the base 43 and the top of the slide bar 42 , the slide bar 42 is provided with a drive mechanism 5 that drives the slide bar 42 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com