Wheel-Guiding Strut For A Motor Vehicle

A technology of guide rods and wheels, applied in the direction of body, vehicle parts, streamlined body, etc., can solve problems such as not being clearly reflected, and achieve the effect of improving air resistance coefficient, large free space for modeling, and reducing fluid separation and eddy current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

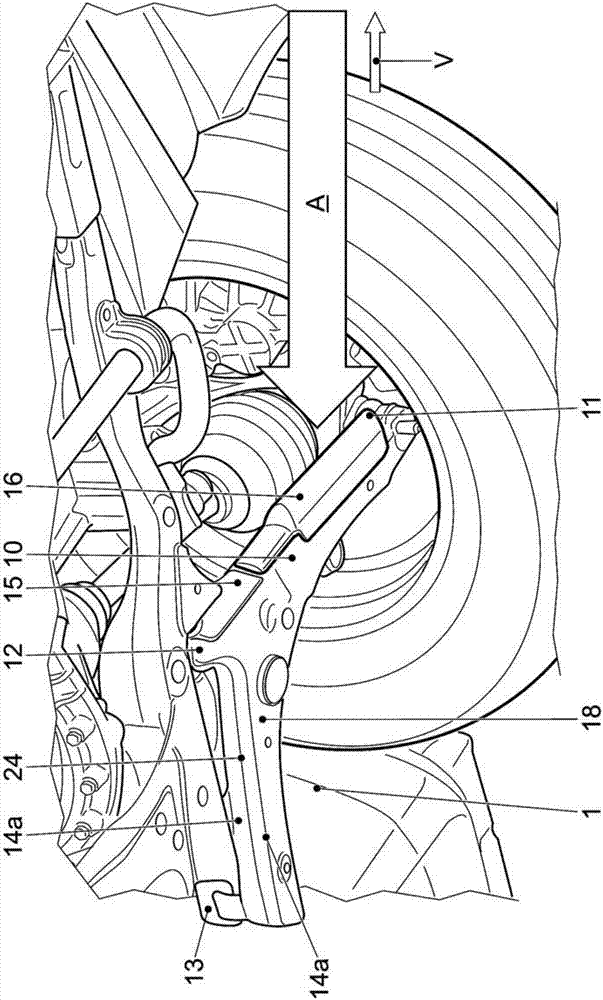

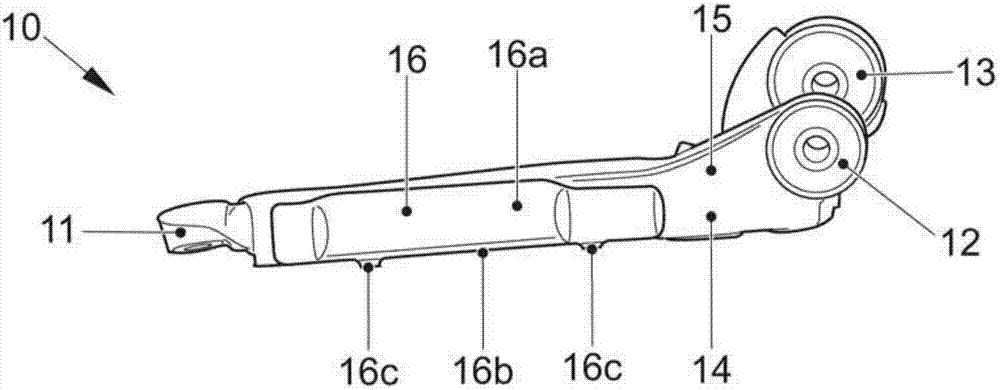

[0024] figure 1 The first exemplary embodiment of the wheel guide 10 according to the invention is shown in the installed position on the motor vehicle 1 . Wheel guide bars usually support the wheels of a car on its body. If terms such as above, below, front, rear or transverse are used in the following description of the wheel guide arm 10 , they are each referred to the intended general installation position on the motor vehicle.

[0025] In particular, wheel guide struts 10 arranged close to the underbody can be exposed to head-on currents A caused by the driving wind and thus adversely affect the air resistance coefficient of the motor vehicle.

[0026] In the shown first exemplary embodiment, the wheel guide link 10 is shown by way of example as a tie rod. However, the following explanations can likewise be transferred to other types of wheel guide rods 10 .

[0027] The wheel guide link 10 of the first exemplary embodiment accordingly comprises at least one wheel-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com