Portable corn kernel recycling device

A recycling device and a convenient technology, applied in the field of convenient corn kernel recycling devices, can solve the problems of reducing the storage space of the recycling box, increasing the labor intensity of farmers, reducing work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

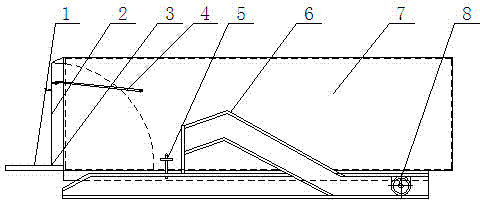

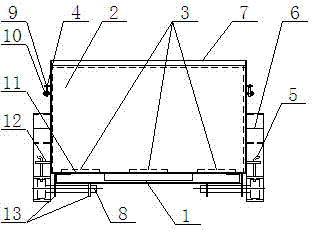

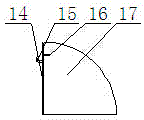

[0023] This convenient corn kernel recovery device includes a handle 1 , an unloading chute 2 , a hinge 3 , a hook 4 , a fixing pin 5 , a rolling groove 6 , a kernel recovery box 7 and a rolling roller device 8 . The handle 1 is welded to the front end of the grain recovery box 7; the unloading chute 2 is connected to the bottom plate 11 of the grain recovery box 7 through three sets of hinges 3; one end of the hook 4 is hooked on the support plate 16 of the side plate 17 of the unloading chute 2, The other end of the ring passes through the stud 9 welded on the side plate of the grain recovery box 7, and the outside is fixed with a nut 10; the fixing pin 5 is inserted through the lug plate 12 welded on the side plate of the grain recovery box 7 and insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com