A point heat source temperature test method for non-direct contact

A testing method and point heat source technology, which is applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electric/magnetic components, can solve the difficulty of directly measuring the temperature of point heat sources, and the test temperature and point heat sources cannot be directly measured. Measurement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

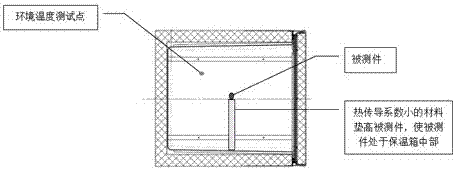

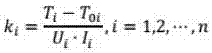

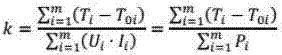

[0016] A point heat source temperature test method that cannot be directly contacted. The test piece is placed in the middle of the incubator, and it is padded with a material with good heat insulation effect and small volume. The purpose is to isolate the disturbance of air convection and the disturbance of external temperature change. Better simulate the environment, so that the thermal conductivity coefficient K value has the same value under the same ambient temperature and the same surface temperature of the tested part; further, the difference between the surface temperature of the tested part and the ambient temperature Under the same conditions, the thermal conductivity coefficient K has the same value. The test point of the ambient temperature is placed at a position that is neither close to the DUT nor close to the box wall. Since the DUT is a point heat source, when the temperature is stable, the influence of the ambient temperature by the heat source will be proport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com