Method for operating a motion device

A movement device and movement technology, applied in the direction of transportation and packaging, power control mechanism, wing leaf control mechanism, etc., can solve the problems of increased load on the mechanical structure, adverse effects on the movement comfort of components, abnormal shaking and swinging, etc., to achieve The effect of preventing overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

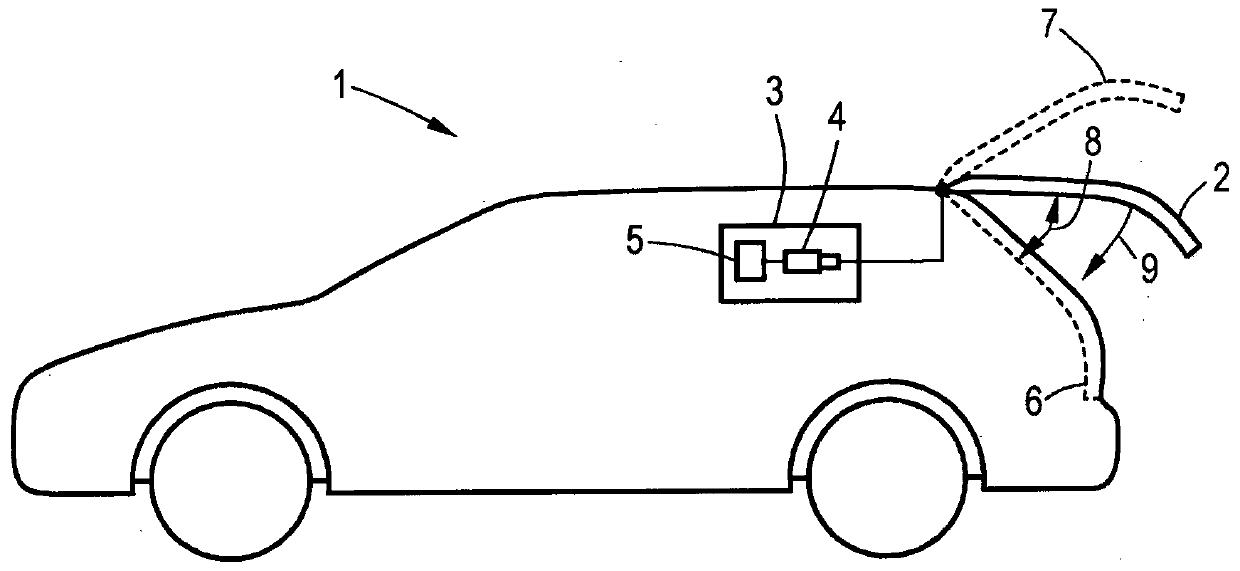

[0021] figure 1 A motor vehicle 1 according to the invention with a rear hood 2 and a movement device 3 with a drive unit 4 , which is controlled by a control unit 5 , is shown in schematic diagram form. Furthermore, the tailgate 2 is shown implicitly in the closed position 6 and in the maximum open position 7 , wherein the shown position of the tailgate 2 is currently the starting position. Positions 6 and 7 are end positions. In addition, the angle of inclination 8 of the rear lid 2 is shown.

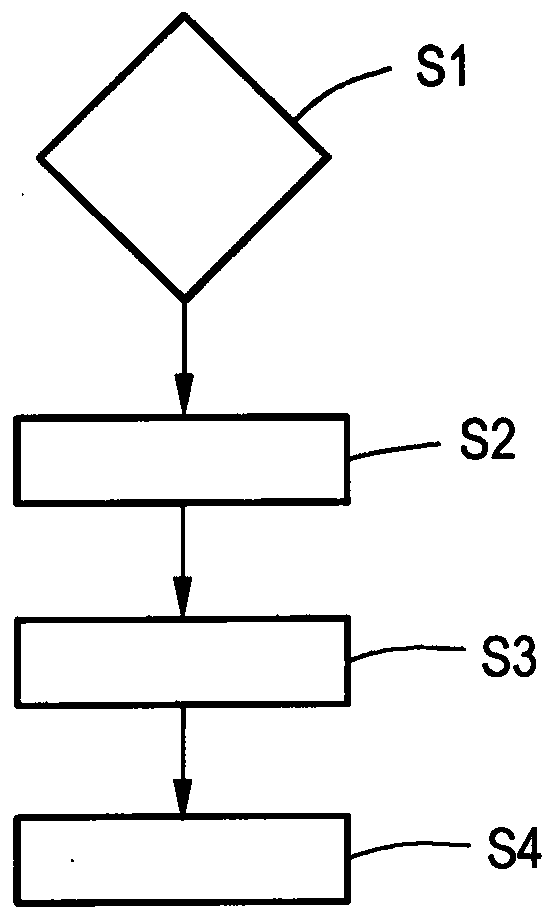

[0022] figure 2 A flow chart of an exemplary embodiment of the method according to the invention is shown. Step S1 here represents the initial state of the method, ie the movement of the rear lid 2 , for example by actuation of an operating element. In step S2, drive parameters are selected on the basis of the current inclination angle 8 representing the starting position and the desired direction of movement 9 . In the present case, this can be achieved, for example, by storing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com