High-precision well track monitoring method

A wellbore trajectory and high-precision technology, applied in construction and other fields, can solve problems such as inaccurate calculation results, affecting the accuracy of wellbore trajectory monitoring, errors, etc., to eliminate errors, solve large errors, and improve accuracy and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

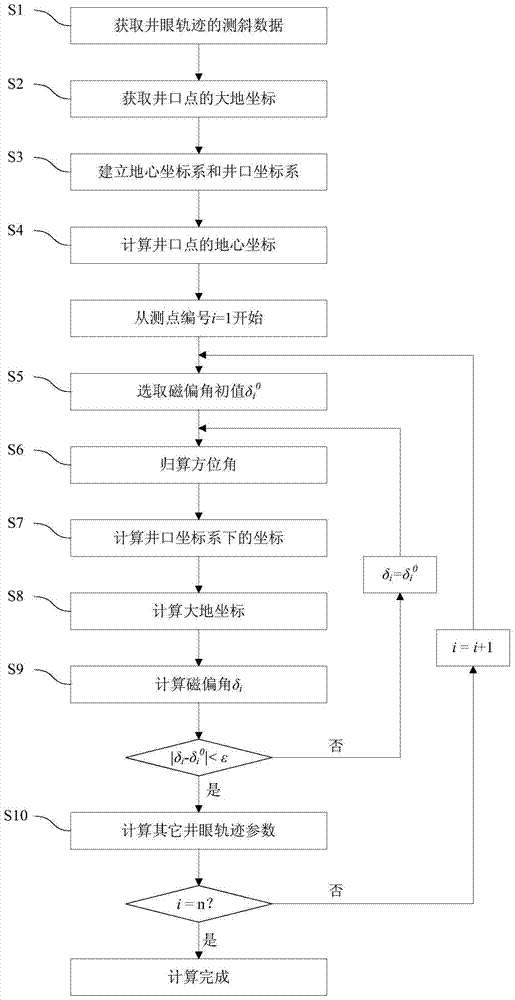

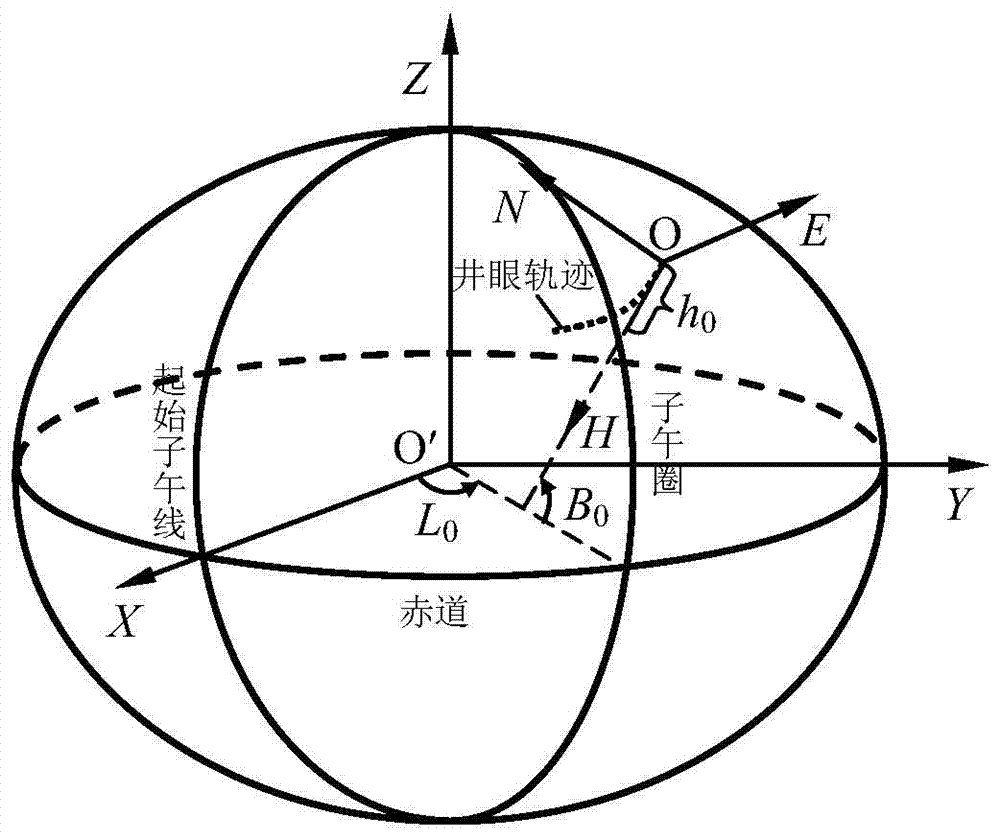

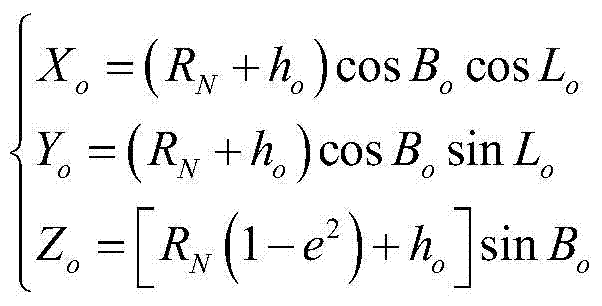

[0049] The basic task of borehole trajectory monitoring is to obtain the spatial coordinates of each measuring point. For this reason, a spatial Cartesian coordinate system O-NEH, referred to as the wellhead coordinate system, is established at the wellhead. For the first measurement point, it can be considered as a measurement section with the wellhead point. The wellhead point is not the actual measuring point, it can be marked with i=0 for convenience. Since all the parameters of the wellhead point are known data, the spatial coordinates of the first measuring point can be obtained as long as the coordinate increment in the measuring section is calculated. The calculation results of the actual drilled wellbore trajectory can be obtained by analogy of the measured section by section. Therefore, the real drilling trajectory monitoring problem can be attributed to the following proposition: on the real drilling trajectory, the inclination data of two adjacent measuring point...

Embodiment 2

[0094] This embodiment is an example of monitoring a horizontal well by using the wellbore trajectory monitoring method provided in the above embodiments.

[0095] The geodetic coordinates of the wellhead point of the horizontal well is the geodetic longitude L 0 =85°20′E, geodetic latitude B 0 =38°50′N, elevation h 0 = 1000.00m, the date of drilling is August 12, 2016. Adopt the natural curve model of wellbore trajectory and the International Geomagnetic Reference Field (IGRF-12) model, see Table 1 and Table 2 for the actual drilling wellbore trajectory calculated by the inclination data according to the prior art and the method of the present invention.

[0096] Table 1. Wellbore trajectory monitoring results of the prior art

[0097]

[0098] Table 2 Borehole trajectory monitoring results of the embodiment of the present invention

[0099]

[0100]

[0101] The results show that the vertical depth and horizontal length of each measuring point calculated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com