Liftable cleaning type dyeing equipment

A technology of dyeing equipment and supporting components, which is applied in the direction of textile material cleaning device, spray/jet textile material treatment, etc. It can solve the problems of poor dyeing quality, inconvenient disassembly of dyeing equipment, and difficulty in quick disassembly, quick positioning and fixing, etc. , to achieve the effect of easy operation, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

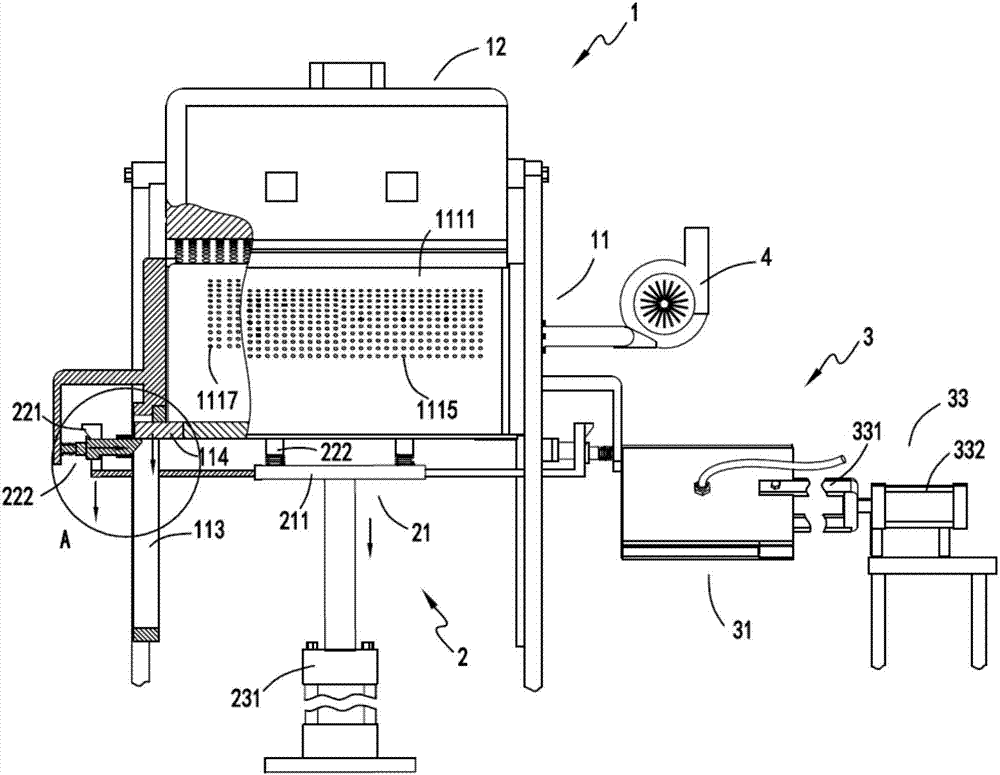

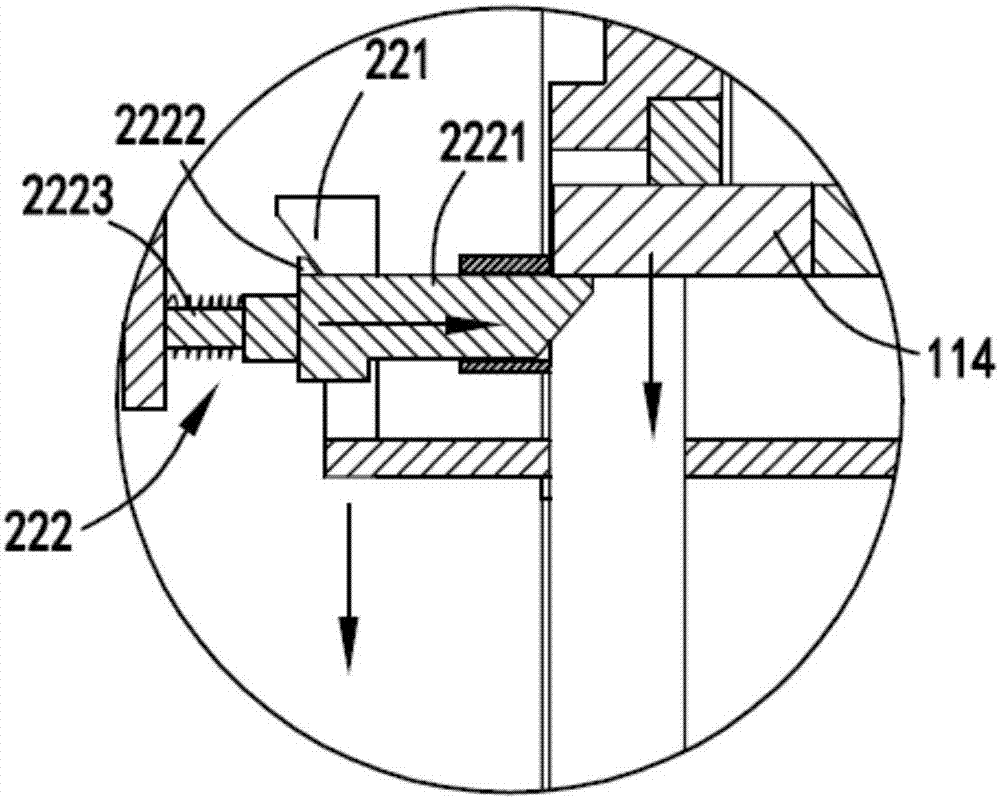

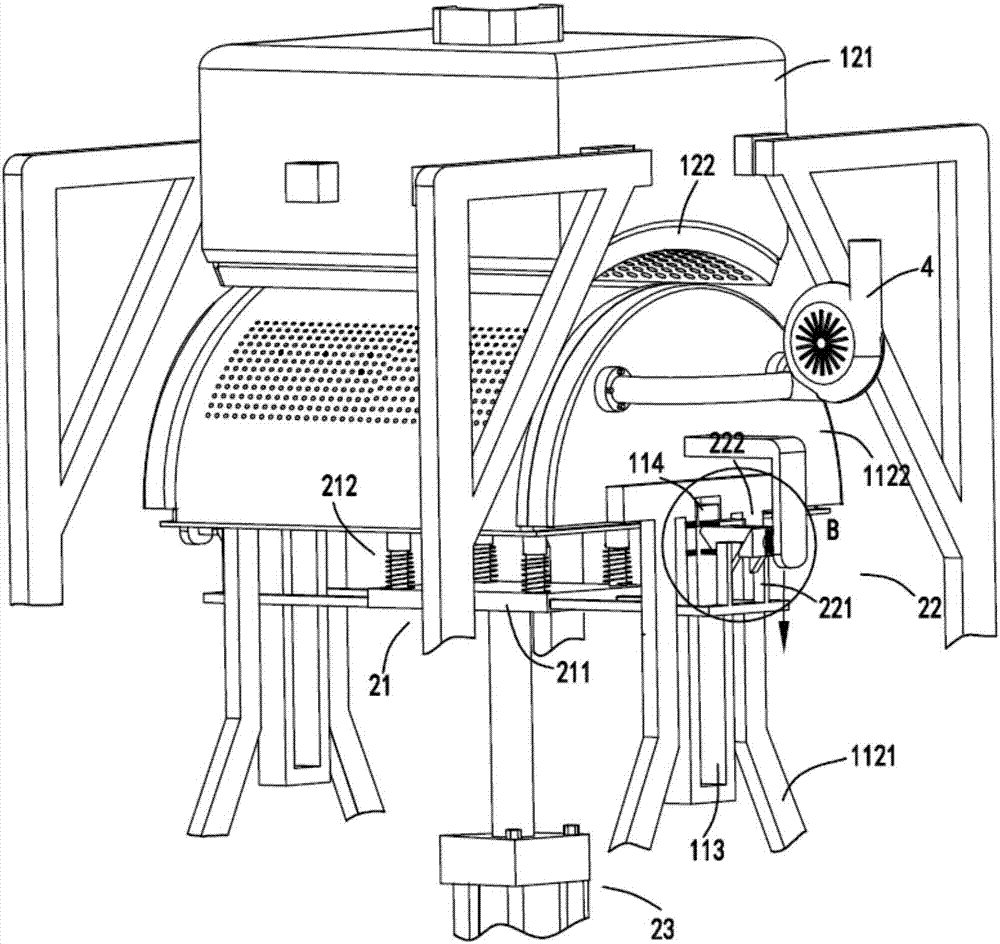

[0046] figure 1 It is a schematic diagram of the front view of the lifting and cleaning dyeing equipment, figure 2 Schematic diagram of the enlarged structure of the locking assembly, image 3 It is a schematic diagram of the structure when the supporting component is lowered, Figure 4 Schematic diagram of the enlarged structure of the locking assembly when the supporting assembly is lowered, Figure 5 It is a schematic diagram of the structure when the supporting component rises, Image 6 Schematic diagram of the enlarged structure of the locking assembly when the support assembly is raised, Figure 7 It is a schematic diagram of the structure of the scrubbing assembly, Figure 8 Schematic diagram of the structure of the auxiliary mechanism, Figure 9 is a schematic diagram of the structure of the slider unit, Figure 10 is a schematic diagram of the structure of the conduction device, Figure 11 is a schematic diagram of the cloth passing through the support component...

Embodiment 2

[0065] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the outer port of the wrinkle removal hole 1115 on the left side is inclined toward the center position on the arc surface corresponding to the negative pressure chamber a1114 with the center position as the dividing line, and the outer port on the right side is inclined towards the center position. The outer port of the corrugation hole 1115 is also inclined towards the center position.

[0066] The negative pressure chamber a1114 and the wrinkle removal hole 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com