Gray cloth defect visual inspection equipment and method

A visual detection and defect technology, applied in the direction of optical testing defects/defects, etc., can solve the problems of high price, poor stability, popularization and promotion of automatic cloth inspection machines, and insufficient technical maturity, so as to increase production efficiency and reduce labor intensity. , the effect of real-time guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

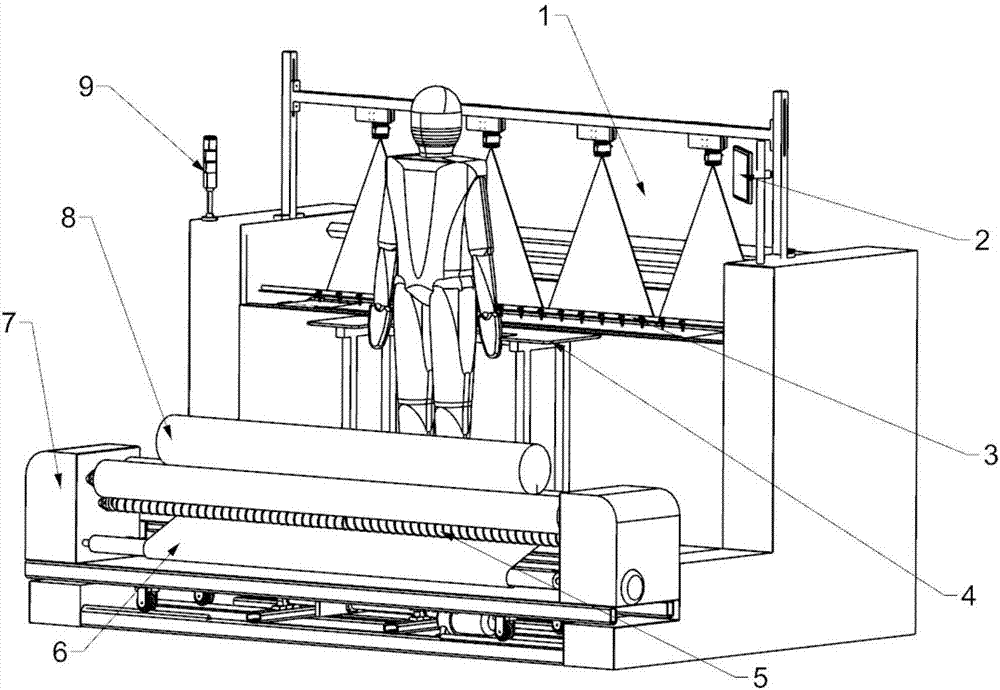

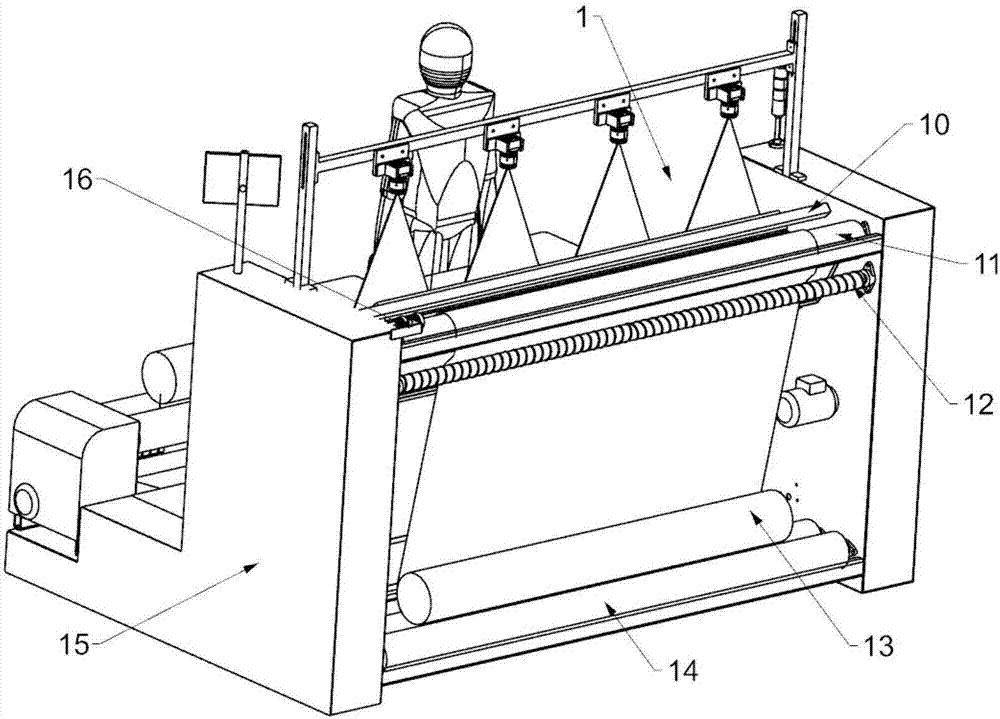

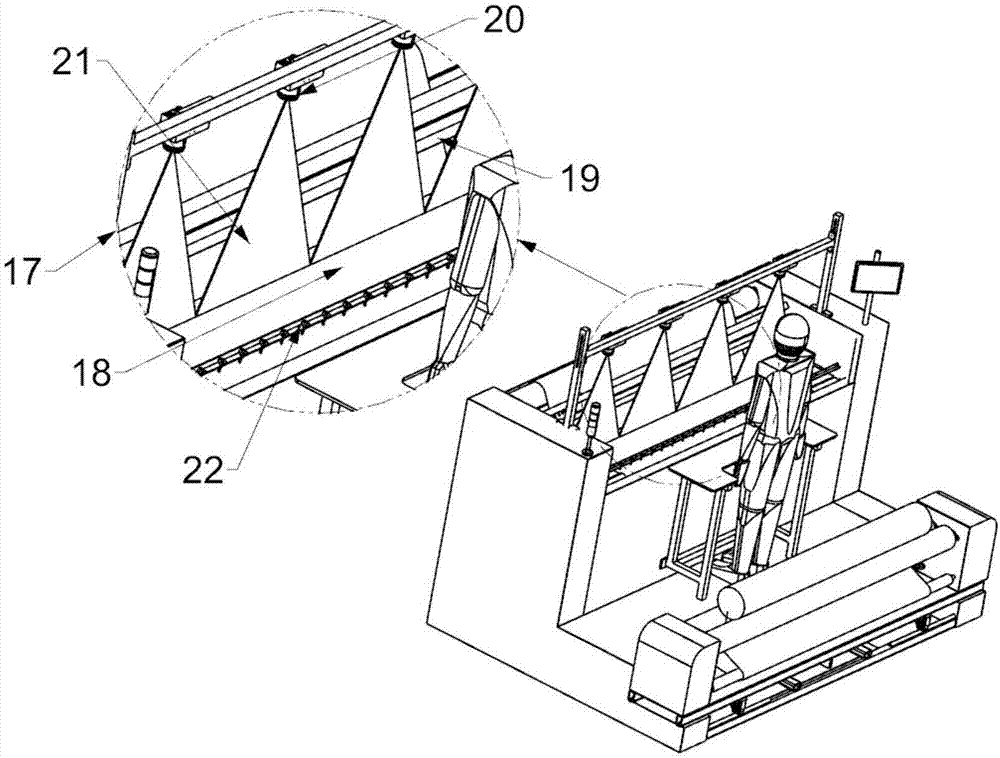

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0046] Aiming at the deficiencies of the existing detection technology, combined with the needs of various weaving factories, the present invention provides a visual detection device for gray cloth defects, which can automatically detect gray cloth defects and save the defect data in the local database. Its detection speed and The detection rate is much higher than that of manual inspection, which increases the production efficiency of the textile mill, greatly reduces the labor intensity, and reduces the labor cost of the textile factory in quality inspection. Simultaneously, the invention also provides a multi-thread-based gray cloth quality detection algorithm framework, so that the real-time performance of the algorithm is guaranteed. The maximum detection speed of the solution reaches 6.5 m / s, and the maximum detection width is 2 meters.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com