Novel gear phase detection tool

A phase detection and gear technology, applied in the direction of angle/taper measurement, etc., can solve the problems of slow detection efficiency, long detection time, and deviation strike of the three-coordinate measuring instrument, so as to improve the gear phase detection efficiency, easy to operate, and reduce time consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

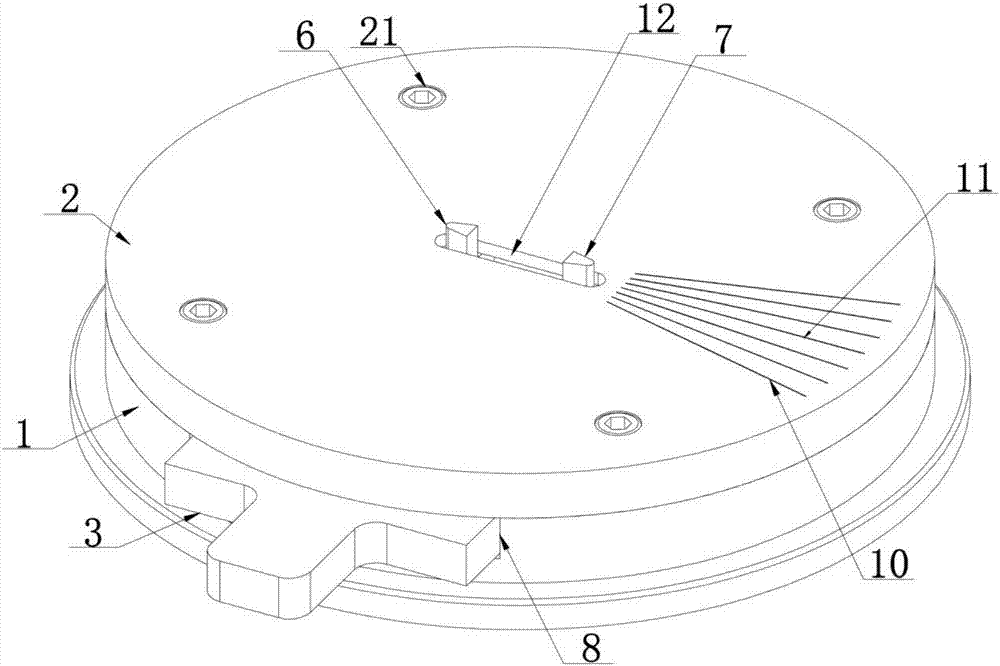

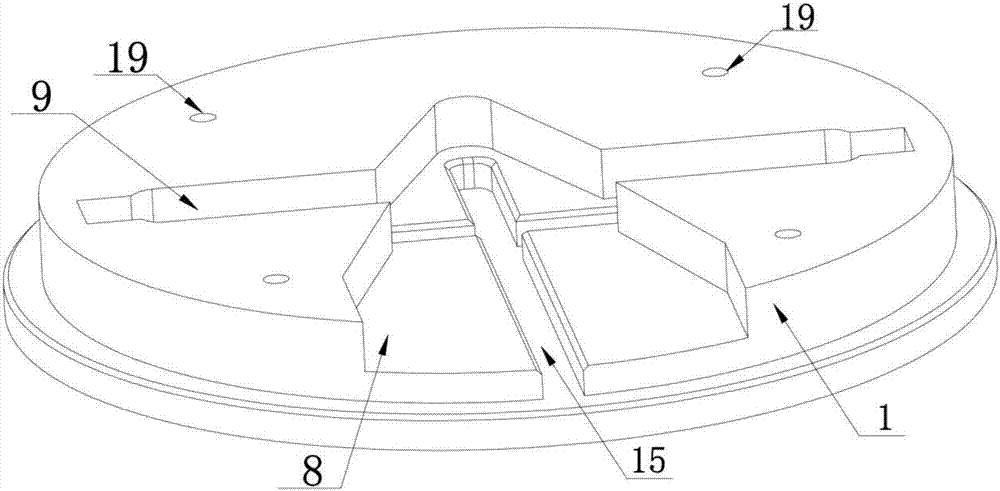

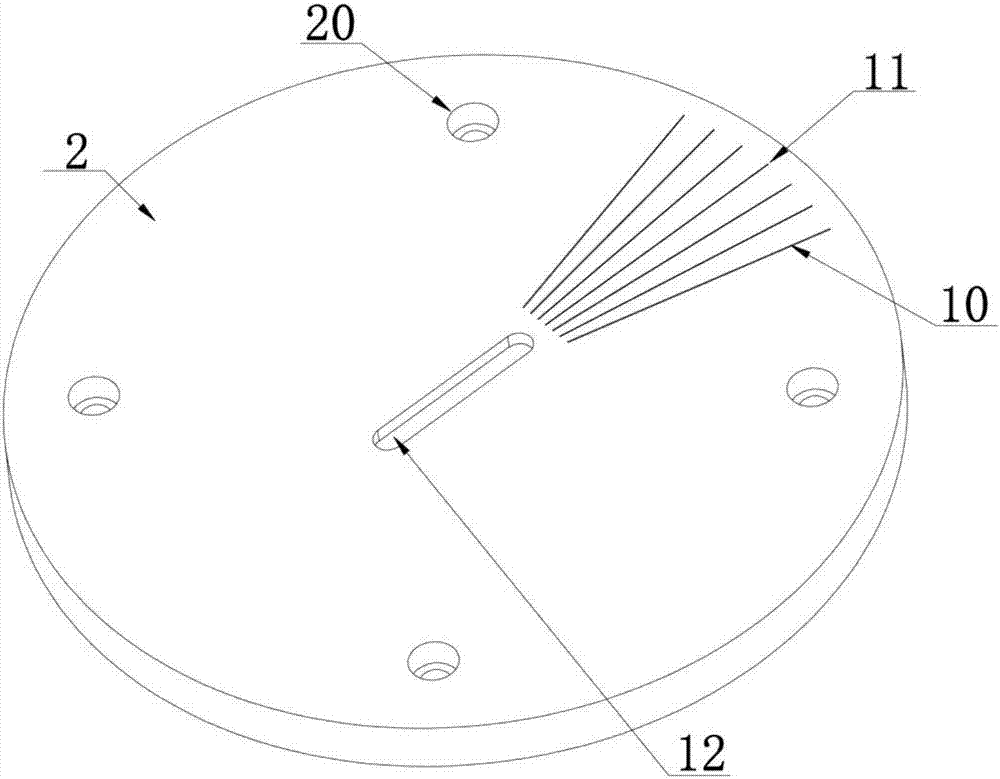

[0032] Such as Figure 1-Figure 8 As shown, a new type of gear phase detection tool includes a base 1, an upper end cover 2, a push plate 3 and a positioning mechanism. The top of the claw corresponds to the left top 6 and the right top 7 matched with the inner spline of the gear. The outer ends of the left and right claws are respectively connected to the base 1 through telescopic springs. The push plate groove 8 matched with the push plate, the left and right claws slide in the positioning chute 9 under the action of the push plate, and the positioning chute is symmetrically arranged on the two sides of the push plate groove. On the base, the positioning chute and the push plate groove are vertically arranged, the telescopic spring is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com