Multi-angle automobile lifting device and using method thereof

A lifting device, multi-angle technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of endangering human safety and health, causing occupational diseases, and easy fatigue of car maintenance personnel, so as to achieve the minimization of car lifting devices, convenient movement and Store and avoid the effect of muscle strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

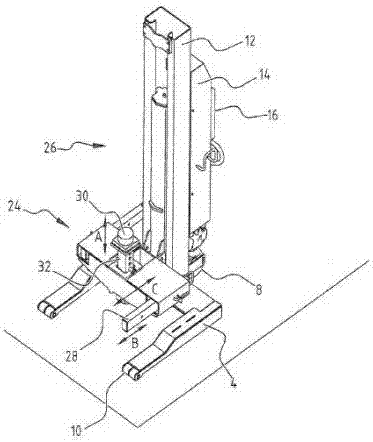

[0033] Multi-angle car lifting device, such as figure 1 As shown, it includes a column 12, a lifting platform, a base 4 and a central controller 14.

[0034] A hydraulic drive device 26 is installed in the column 12, and the hydraulic drive device 26 is connected with more than two lifting arms 28 that can freely expand and contract along the direction of the central axis. The lifting arms 28 are arranged in parallel and are respectively connected to the The lifting platform 24 is connected to support the rising and falling of the car. The lifting platform 24 can move back and forth along the lifting arm 28 to reach a certain position at the bottom of the vehicle. The hydraulic drive device 26 drives the lifting arm 28 and the lifting platform 24 to move up and down along the vertical direction of the column, and at the same time, the lifting arm 28 drives the vehicle to move up and down.

[0035] In this embodiment, the lifting arm 28 passes through the inside of the liftin...

Embodiment 2

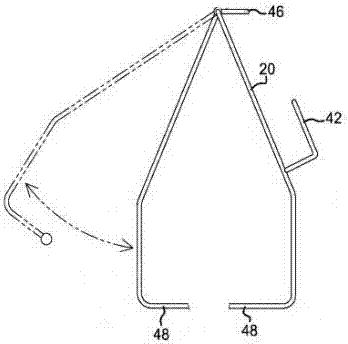

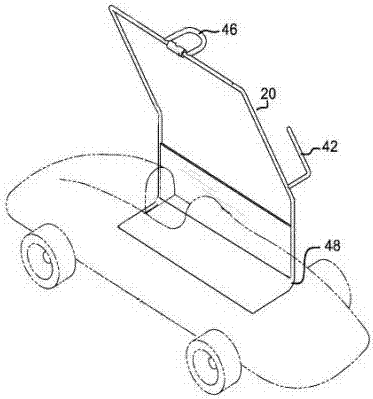

[0048] Due to the movement of the center of gravity during the turning process of the car, one side of the car is lifted to a certain height. When the car is at a certain angle with the ground, it is easy to have a slight collision or other external force, and the car will completely turn over, threatening the body of the car maintenance personnel present. Health and life safety, while causing damage to the car. Therefore, it is necessary to fix the car during the overturning process of the car, so as to avoid the danger, and at the same time, it is convenient for the car maintenance personnel to overhaul the car.

[0049]The upper surface of the lifting arm 28 is covered with a fixed plate 48, the fixed plate 48 is composed of two plates hinged to each other, and the hinge of the fixed plate 48 is provided with a buffer area. A fixed frame 20 is hinged on the upwardly folded flat plate, and in this embodiment, the fixed frame 20 is a square frame. When used specifically, suc...

Embodiment 3

[0061] The lifting arm 28 is fixedly connected to the lifting platform 24 , and during specific use, the lifting arm 28 drives the lifting platform 24 to move when stretching along its central axis.

[0062] All the other are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com