Weaving method for multi-layer and multi-direction fabric

A fabric and oblique technology, applied in the weaving field of multi-layer multi-directional fabrics, can solve the problems of limited designability of fabric structure and mechanical properties, failure to meet the shear resistance of composite materials, etc., to meet the needs of low-cost manufacturing , Improved in-plane shear performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

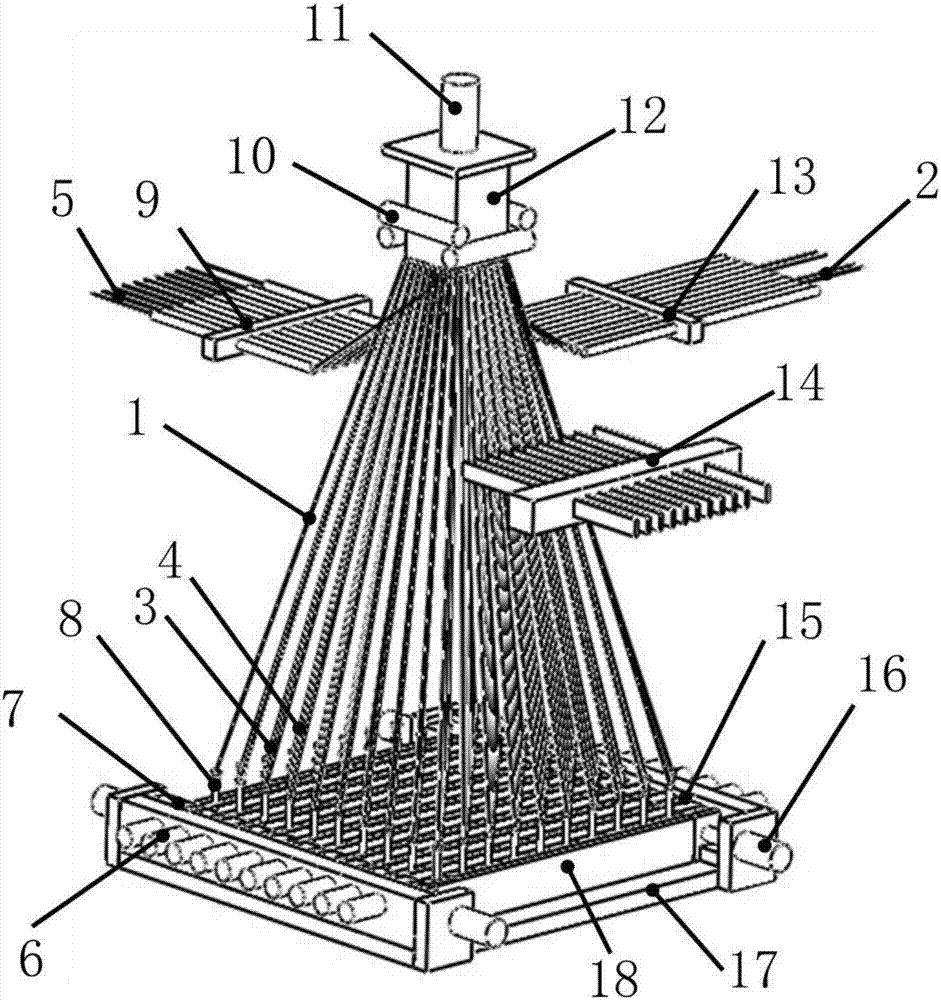

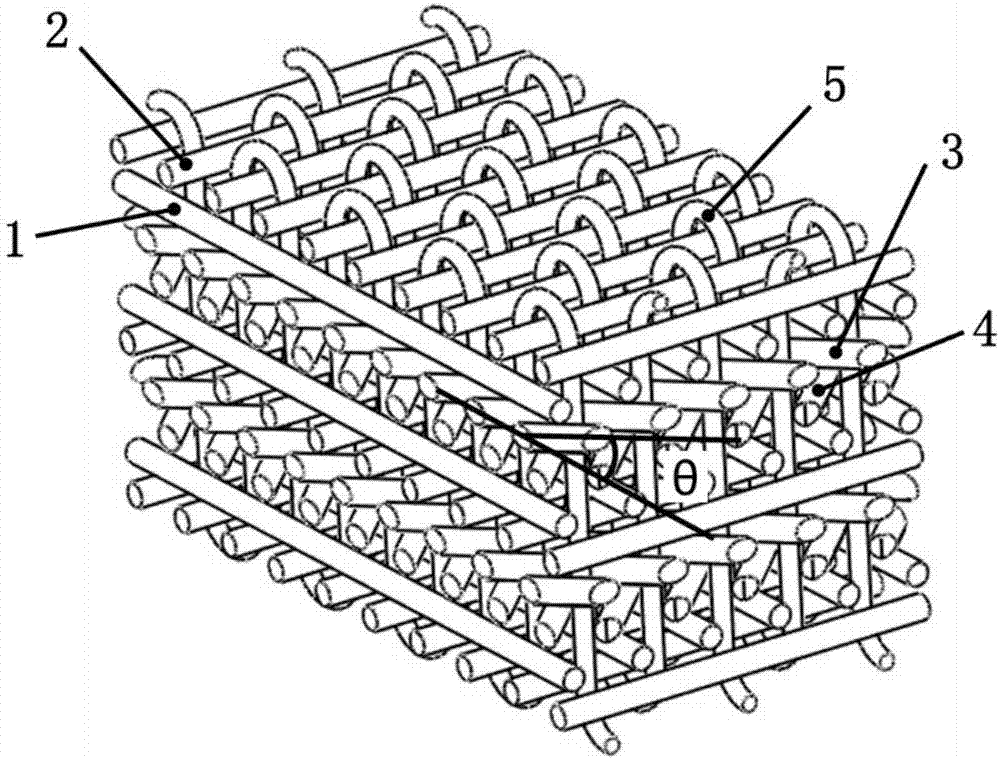

[0045] Develop multi-layer multi-directional fabrics with 10 layers, such as figure 2 shown. The width of the fabric is 30cm, including warp yarn 1, weft yarn 2, +θ oblique yarn 3, -θ oblique yarn 4 and normal yarn 5, all using 12K carbon fiber. The warp yarn density is 5 yarns / cm, and the weft yarn density is 5 yarns / cm. The angle between the oblique yarn and the length direction of the fabric is 45°. The arrangement of yarn layers in the thickness direction of the fabric is [90 / 0 / -45 / +45 / 90 / 0 / -45 / +45 / 0 / 90], where: 0 represents 0° warp yarn 1, 90 represents 90° weft yarn 2, +45 represents +θ diagonal yarn 3, and -45 represents -θ diagonal yarn 4. Its weaving method specifically comprises the following steps:

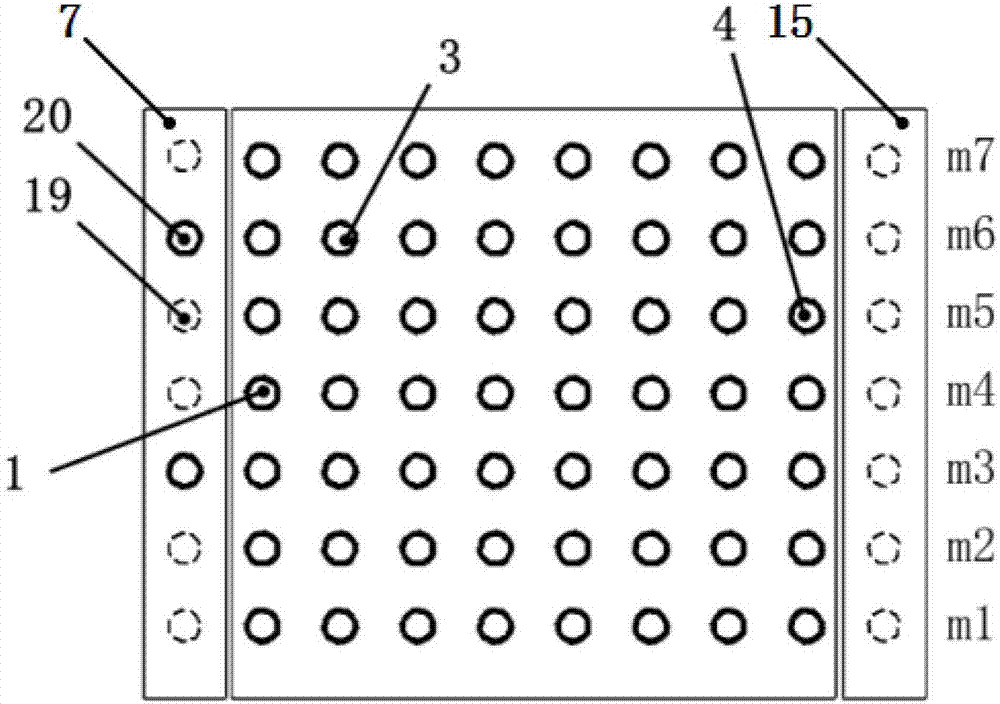

[0046] (1) Main yarn arrangement: According to the design requirements of the fabric structure, the arrangement of the yarn layers of the fabric is [90 / 0 / -45 / +45 / 90 / 0 / -45 / +45 / 0 / 90]. The initial arrangement of main yarns only considers warp yarn 1, +θ oblique yarn ...

Embodiment 2

[0055] A multi-layer multi-directional fabric of 13 layers was developed. The width of the fabric is 50 cm, including warp yarn 1, weft yarn 2, +θ diagonal yarn 3, -θ diagonal yarn 4 and normal yarn 5. Warp yarn 1, weft yarn 2, +θ oblique yarn 3, and -θ oblique yarn 4 all use 190Tex×4 strands of quartz fiber, and the normal yarn uses 190Tex×2 strands of quartz fiber. The warp yarn density is 6 yarns / cm, the angle between the oblique yarn and the fabric length direction is 60°, and the weft yarn density is 5.2 yarns / cm. The arrangement of the yarn layers in the thickness direction of the fabric is [90 / -60 / 0 / +60 / 90 / -60 / 0 / +60 / 90 / -60 / 0 / +60 / 90]. Its weaving method specifically comprises the following steps:

[0056] (1) Main yarn arrangement: According to the design requirements of the fabric structure, the arrangement of the yarn layers of the fabric is [90 / -60 / 0 / +60 / 90 / -60 / 0 / +60 / 90 / -60 / 0 / +60 / 90]. The initial arrangement of main yarns only considers warp yarn 1, +θ oblique ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com