An extendable steel bracket for solar photovoltaic panel power station

A technology of solar photovoltaic panels and power stations, applied in photovoltaic power generation, support structures of photovoltaic modules, photovoltaic modules, etc., can solve problems such as non-adjustable bracket angles and inconvenient installation of extended brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

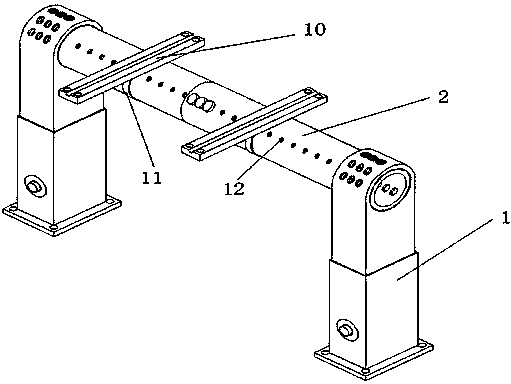

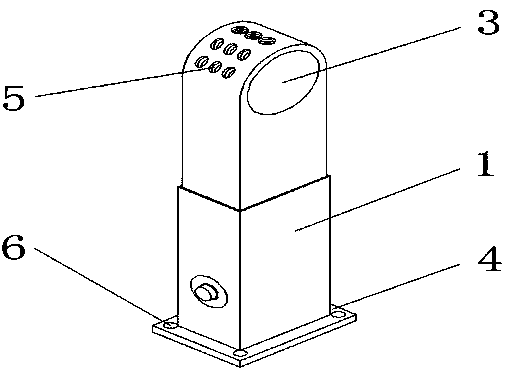

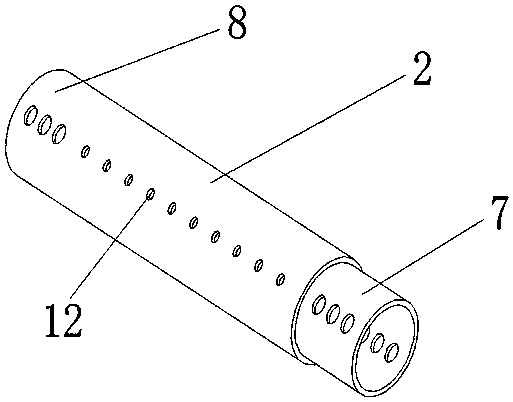

[0016] Such as Figure 1-5 As shown, an extendable solar photovoltaic panel power station steel bracket includes a support column 1 and a connecting pipe 2. The height of the support column 1 can be adjusted, and the support column 1 is provided with a connection hole 3 and a connection plate 4 for connection. , the connection hole 3 is opened on the side of the support column 1, and the outside of the connection hole 3 is uniformly provided with an angle adjustment hole 5, the connection plate 4 is welded to the bottom of the support column 1, and the ground anchor hole 6 is opened on the corner of the connection plate 4, and the connection pipe 2 Transversely installed in the connecting hole 3, the connecting pipe 2 is provided with a connecting male 7, a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com