Method for determining minimum replacement thicknesses of ballastless track swelling soil cuttings and low-embankment bases

A ballastless track, determination method technology, applied in the fields of instrument, geometric CAD, calculation, etc., can solve the problems of non-uniform excavation and replacement thickness standards, lack of calculation theory, and ballastless track diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

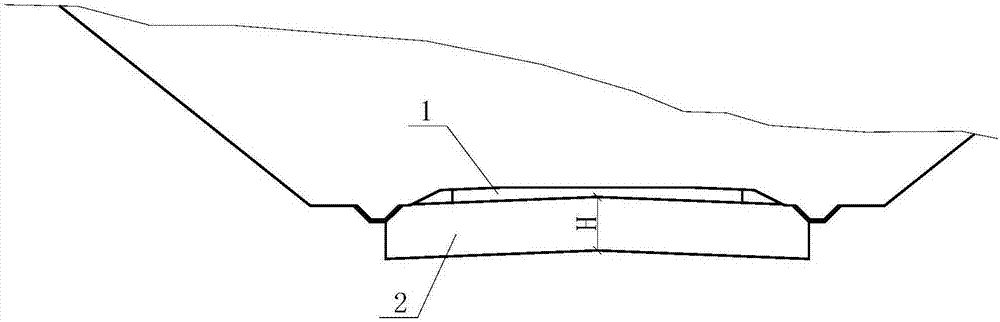

[0037] refer to figure 1 The excavation depth of an expansive rock-soil cutting on Iran’s Dehran-Qom-Isfahan high-speed railway was 6.39m, the width of the top surface of the cutting bed was 13.4m, and the cutting-side-slope ratio was 1:1.25. The thickness of the cutting base replacement body is H.

[0038] figure 1 Among them, the mark 1 is the surface layer of the foundation bed, and the mark 2 is the base replacement body.

[0039] Step ①, according to the deformation control requirements of high-speed railway ballastless track, the allowable uplift deformation of the top surface of the surface layer 1 of the expansive rock-soil cutting subgrade Take 1.0mm.

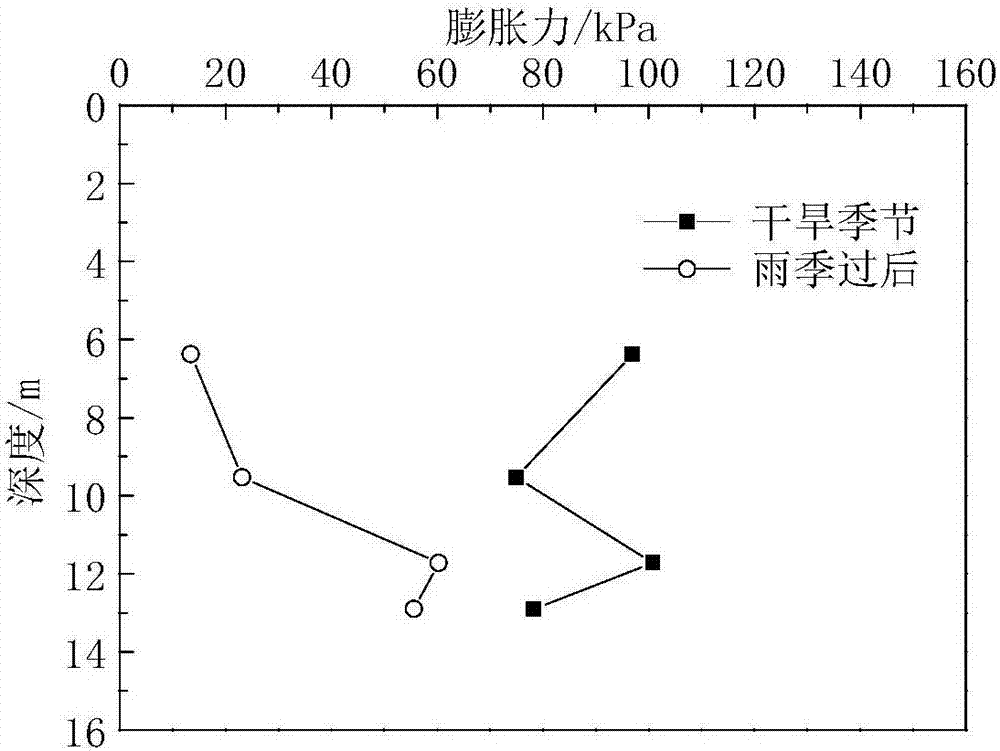

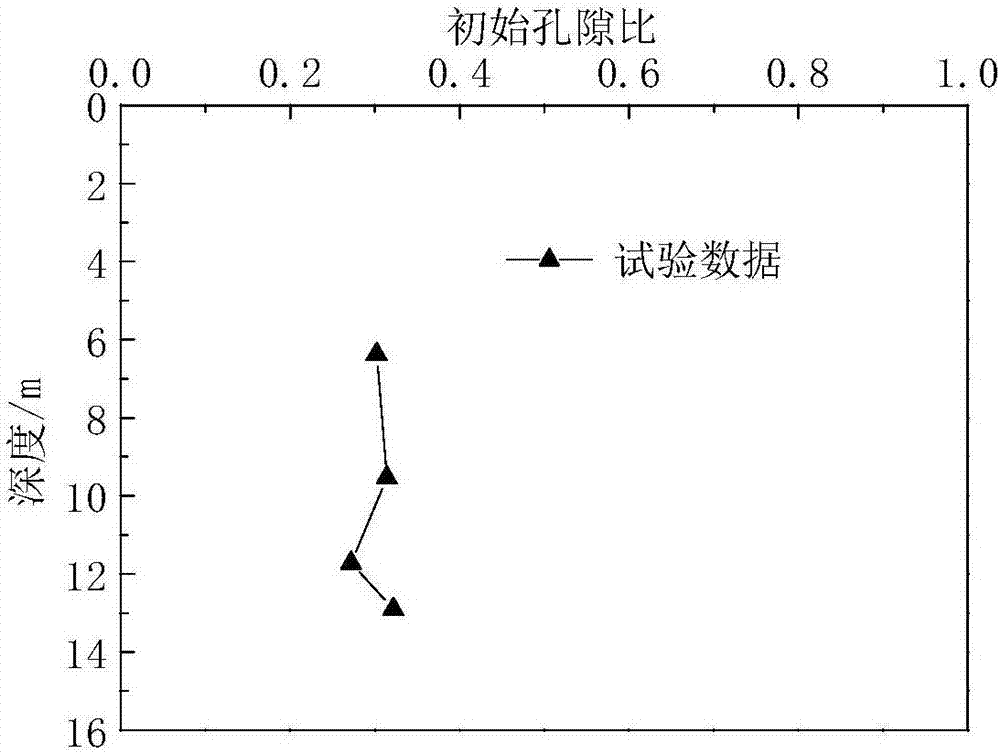

[0040] Step ②, through on-site geological drilling and indoor geotechnical testing, the expansion force σ of the expansive rock and soil layer in the dry season is obtained sN and the remaining expansive force σ of the expansive soil layer after the rainy season sP Along the depth distribution see figure 2 , th...

Embodiment 2

[0048] refer to Figure 5 The filling height of the low embankment on a certain expansive rock soil of Yungui (Kunming to Nanning) high-speed railway in China is 1.60m, the width of the top surface of the subgrade bed of the low embankment is 13.4m, the slope ratio of the low embankment is 1:1.5, and the low embankment The thickness of the base replacement body is H.

[0049] Figure 5 Among them, mark 1 is the surface layer of the subgrade bed, mark 2 is the base replacement body, and mark 3 is the low embankment filling body.

[0050] Step ①, according to the deformation control requirements of high-speed railway ballastless track, the allowable uplift deformation of the top surface of the surface layer 1 of the expansive rock-soil low embankment bed Take 1.0mm.

[0051] Step ②, through on-site geological drilling and indoor geotechnical testing, the expansion force σ of the expansive rock and soil layer in the dry season is obtained sN and the remaining expansive force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com