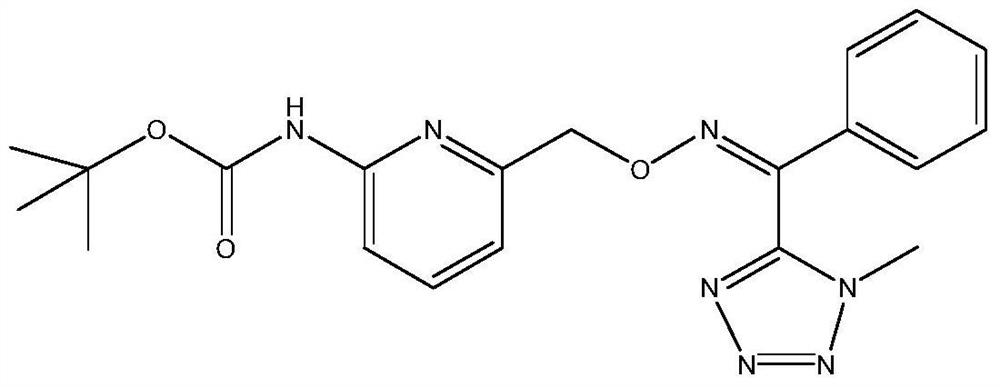

Bactericidal composition containing picarbutrazox and its preparation and application

A composition and preparation technology, applied in the field of fungicidal active compound composition, can solve the problem that a single fungicidal active compound cannot prevent and control multiple diseases at the same time, and achieve the effects of reducing the risk of resistance, reducing the pressure on the environment, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

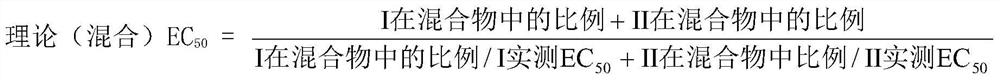

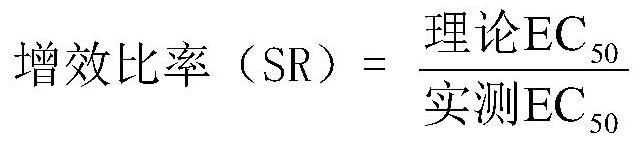

Method used

Image

Examples

Embodiment 1

[0130] 30% active compound (20.0% picarbutrazox and 10.0% zinc 2-mercaptobenzothiazole composition), alkylnaphthalene sulfonate 2.0%, phenolsulfonic acid condensate sodium salt 1.0%, methylnaphthalenesulfonate sodium formaldehyde condensation Compound 2.0%, sodium starch octenyl succinate 2.0%, glycerin 2.0%, silicone defoamer 0.1%, isothiazolinone 0.2%, tap water to make up to 100%, put into high shear homogenization High-speed shearing in an emulsifier for 25 minutes, then pumped to a sand mill for sand grinding for 90 minutes, and 30% active compound suspending agent is obtained after filtration.

Embodiment 2

[0132] 35% active compound (20.0% picarbutrazox and 15.0% oxalaxyl composition), alkylnaphthalene sulfonate 3.0%, sodium methylnaphthalene sulfonate formaldehyde condensate 2.0%, sodium starch octenylsuccinate 2.0%, Glycerol 2.0%, silicone defoamer 0.1%, isothiazolinone 0.2%, deionized water to make up to 100%, put into a high-shear homogeneous emulsifier for high-speed shearing for 25 minutes, and then pump to Sand milled in a sand mill for 90 minutes and filtered to obtain 35% active compound suspending agent.

Embodiment 3

[0134] 40% of active compounds (20.0% of picarbutrazox and 20.0% of isocyanurate composition), fatty alcohol polyoxyethylene ether 1.0%, sodium lignosulfonate 1.0%, high molecular polycarboxylate 4.0%, epoxidized soybean oil 5.0% %, ethylene glycol 3.0%, silicone defoamer 0.1%, formaldehyde 0.2%, tap water to make up to 100%, put into a high-shear homogeneous emulsifier for high-speed shearing for 30 minutes, and then transported to a sand mill, The 40% active compound suspending agent can be obtained by circulating sanding 1-3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com