Seeding device

A sowing device and a technology of a seeding port, which is applied to the parts of a seeder, manual sowing tools, etc., can solve the problems of not being able to sow seeds with a large difference in seed size at the same time, poor use effect, and poor stability of the cable drive mode. Achieve the effect of convenient operation, high seeding precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

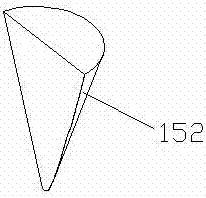

[0032] Such as figure 1 As shown, a sowing device of the present invention includes a housing 11, a first partition 12, a pressing rod 13, a spring 14, a seeding nozzle 151, a soil block 152, a first connecting rod 16, a gear 17, and a rack 18 And the seeding mechanism 2, the first partition 12 is located in the housing 11, and the inner cavity of the housing 11 is divided into an installation chamber 110 and a seeding chamber 111, and the bottom of the housing 11 is provided with the seeding chamber 111 through the discharge port, the seed nozzle 151 is fixed on the discharge port, the earth block 152 is hinged on the side wall of the discharge port, and the two gears 17 are rotated in the seed discharge chamber 111, and the two are meshed with each other. The upper end of the first connecting rod 16 is respectively hinged on the two gears 17, and the lower end is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com